Product Description

Product Description

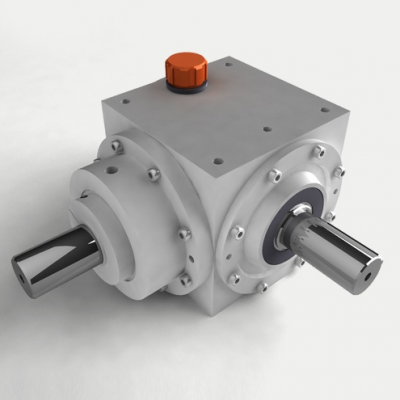

-K Series Helical Bevel Gearbox

K series gear reducer, manufactured according to international technical requirements, has a high scientific and technological content; Space saving, reliable and durable, high overload capacity, power up to 132KW; Low energy consumption, superior performance, reducer efficiency up to 95%

It is designed and manufactured on the basis of module combination system. There are a lot of motor combinations, installation forms and structural schemes. The transmission ratio is classified carefully to meet different operating conditions and realize electromechanical integration.

High transmission efficiency, low energy consumption and superior performance.

Reinforced high rigid cast iron box; The hardened gear is made of high-quality alloy steel. Its surface is carburized, quenched and hardened, and the gear is finely ground. It features stable transmission, low noise, large bearing capacity, low temperature rise, and long service life. Performance and characteristics:

1. The gear is carburized and quenched with high-quality alloy, the hardness of the tooth surface is up to 60 ± 2hrc, and the grinding accuracy of the tooth surface is up to 5-6

2. The computer modification technology is used to pre modify the gear, which greatly improves the bearing capacity of the reducer

3. Complete modular structure design is adopted from the box to the internal gear, which is suitable for large-scale production and flexible selection

4. The standard reducer models are divided according to the form of decreasing torque. Compared with the traditional equal proportion division, they are more in line with customer requirements and avoid power waste

5. It is designed and manufactured by cad/cam to ensure the stability of quality

6. Multiple sealing structures are adopted to prevent oil leakage

7. Multi directional noise reduction measures to ensure the excellent low noise performance of the reducer

8. The installation mode of Liyi products is flexible, which makes it easy for customers to choose K57 reducer, K67 reducer, K77 reducer, K87 reducer, K97 reducer, KA87 reducer, KA97 reducer, KA107 reducer, KA127 reducer

Product Features

1. Input mode: Coupled motor, belted motor, input shaft or connection flange.

2. Output: Right angle

3. Compact structure. Rigid tooth face. Carrying greater torque, high loading capacity.

4.High precision gear, ensuring the unit to operate stably, smooth transmission.

5. Low noise, long lifespan. Large overlap coefficient, abrasion resistant.

Our product line

| Hardness: | Hardened Tooth Surface |

|---|---|

| Installation: | 90 Degree |

| Layout: | Expansion |

| Gear Shape: | Bevel Gear |

| Step: | Single-Step |

| Type: | Gear Reducer |

| Samples: |

US$ 1000/Piece

1 Piece(Min.Order) | |

|---|

Contribution of Spiral Bevel Gearboxes to Mechanical System Efficiency

Spiral bevel gearboxes play a crucial role in enhancing the overall efficiency of mechanical systems by:

- Power Transmission: Spiral bevel gearboxes efficiently transmit power between non-parallel and intersecting shafts, allowing mechanical systems to transfer rotational motion with minimal energy loss.

- High Efficiency: The unique tooth geometry of spiral bevel gears ensures smooth and continuous contact between gear teeth, resulting in higher mechanical efficiency compared to other types of gearboxes.

- Optimized Torque Distribution: Spiral bevel gearboxes distribute torque uniformly across the gear teeth, minimizing the concentration of stress and wear on specific teeth. This leads to improved load-sharing capabilities and reduced mechanical losses.

- Reduced Friction and Heat Generation: The rolling action of spiral bevel gears reduces sliding friction, minimizing heat generation and energy losses that often occur in sliding contact gear systems.

- Noise and Vibration Reduction: The meshing of spiral bevel gears generates less noise and vibration compared to other gear types, resulting in smoother and quieter operation.

- Compact Design: Spiral bevel gearboxes can be designed with a compact form factor, allowing for efficient utilization of space in various mechanical systems.

- Customizable Ratios: Gear ratios in spiral bevel gearboxes can be tailored to specific application requirements, ensuring optimal speed and torque matching.

- Reliable Power Transfer: Spiral bevel gears’ robust design and accurate tooth meshing contribute to reliable power transfer even under varying loads and operating conditions.

- Long Service Life: Properly designed and maintained spiral bevel gearboxes exhibit high durability and wear resistance, contributing to extended service life.

By effectively transmitting power, optimizing torque distribution, reducing friction, and providing smooth and reliable operation, spiral bevel gearboxes significantly enhance the overall efficiency of mechanical systems in various industries.

Emerging Trends in Spiral Bevel Gearbox Technology

The field of spiral bevel gearbox technology is witnessing several emerging trends that are shaping the future of these components:

- Advanced Materials: Manufacturers are exploring new materials and alloys to enhance the strength, durability, and heat resistance of spiral bevel gearboxes.

- Precision Manufacturing: Advancements in manufacturing technologies, such as CNC machining and 3D printing, are enabling more precise and efficient production of gear components.

- Improved Lubrication: Research into advanced lubricants and lubrication systems is resulting in better performance, reduced friction, and extended service intervals.

- Condition Monitoring: Integration of sensors and monitoring systems allows real-time tracking of gearbox health, facilitating predictive maintenance and minimizing downtime.

- Simulation and Modeling: Computer-aided design (CAD) and simulation tools are being used to optimize gear designs for efficiency, durability, and noise reduction.

- Noise Reduction: Focus on noise reduction techniques is leading to quieter gearboxes, which is especially crucial in noise-sensitive applications.

- Efficiency Enhancement: Innovations in gear profile design and tooth modifications are improving gearbox efficiency, translating to energy savings.

- Compact Design: Demand for compact and space-efficient gearboxes is driving innovations in compact spiral bevel gearbox designs.

- Customization: Manufacturers are increasingly offering customization options to meet specific application requirements.

- IoT Integration: Integration of the Internet of Things (IoT) technology allows remote monitoring and control of gearboxes, enhancing operational efficiency.

These trends reflect the ongoing advancements in spiral bevel gearbox technology, addressing challenges, improving performance, and expanding their applications in various industries.

Industries Using Spiral Bevel Gearboxes

Spiral bevel gearboxes find applications across various industries where precise power transmission, high torque capacity, and efficient motion transfer are essential. Some of the industries that commonly utilize spiral bevel gearboxes include:

- Automotive: Spiral bevel gears are used in automotive differentials, axles, and steering systems to transmit power efficiently and handle changing loads and directions.

- Aerospace: Aerospace applications require reliable and lightweight power transmission, making spiral bevel gears suitable for aircraft engines, landing gear, and control systems.

- Heavy Machinery: Industries like construction, mining, and agriculture use spiral bevel gearboxes in equipment such as excavators, bulldozers, tractors, and loaders.

- Manufacturing: Spiral bevel gears play a role in industrial machinery, conveyors, robotics, and machine tools, ensuring precise motion and power distribution.

- Marine: Marine propulsion systems and steering mechanisms benefit from the robustness and efficiency of spiral bevel gears.

- Energy: Spiral bevel gearboxes are used in power generation equipment, including wind turbines, hydroelectric generators, and gas turbines.

- Railways: Trains rely on spiral bevel gears in their transmission systems and bogie assemblies to deliver power and maintain stability.

The versatility, durability, and reliable performance of spiral bevel gearboxes make them a valuable component in various industrial sectors.

editor by CX 2023-09-08

China Hot selling R K S F Series Speed Reducers Spiral Bevel Gear Reducer Bevel Gearboxes manufacturer

Product Description

| Model Number | F series Parallel Shaft Helical Gear Reducer | Structure Type | F FA FF FAF FAZ |

| Assembly Method | 1-6 | Input power | 0.18-200W |

| Enamelled Wire: | 100% Copper Wire | Reducer body | Steel |

| Ratio | 3.81-267.43 | Brand | FOX MOTOR |

|

Shipping Cost:

Estimated freight per unit. |

To be negotiated |

|---|

| Application: | Motor, Machinery, Agricultural Machinery, paper machine |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal or Vertical |

| Samples: |

US$ 99/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

Lubrication Requirements for Maintaining Spiral Bevel Gearboxes

Lubrication is crucial for ensuring the smooth operation and longevity of spiral bevel gearboxes. Proper lubrication helps reduce friction, prevent wear, dissipate heat, and protect gear components from corrosion. Consider the following lubrication requirements:

- Lubricant Selection: Choose a high-quality lubricant specifically formulated for gear applications. The lubricant should have the appropriate viscosity and additives to withstand the operating conditions and load demands of the gearbox.

- Lubrication Interval: Establish a regular lubrication schedule based on the manufacturer’s recommendations and the application’s operating conditions. Regular lubrication prevents inadequate lubrication and excessive wear.

- Lubrication Method: Depending on the design of the gearbox, lubrication can be achieved through splash lubrication, oil bath lubrication, or forced lubrication systems. Ensure that lubricant is evenly distributed across gear surfaces.

- Quantity: Use the correct amount of lubricant to ensure proper coverage and prevent overfilling, which can lead to excessive heat generation and foaming.

- Temperature: Monitor the operating temperature of the gearbox. Lubricants can degrade at high temperatures, leading to reduced effectiveness. Ensure that the gearbox operates within the recommended temperature range.

- Contamination Control: Keep the lubricant free from contaminants, such as dirt, debris, and water. Regularly check the gearbox’s breathers, filters, and seals to prevent contaminants from entering the system.

- Oil Analysis: Perform regular oil analysis to monitor the condition of the lubricant and identify signs of wear or contamination. Oil analysis helps identify potential issues early and allows for timely corrective actions.

- Re-lubrication After Maintenance: Whenever maintenance is performed on the gearbox, ensure that proper lubrication is applied before restarting the equipment. This prevents dry starts and ensures immediate lubrication to critical components.

Adhering to proper lubrication requirements and practices is essential for maximizing the performance, efficiency, and lifespan of spiral bevel gearboxes in industrial applications.

Extending the Lifespan of Spiral Bevel Gearboxes through Maintenance

To ensure the longevity of spiral bevel gearboxes, the following maintenance practices are essential:

- Regular Inspection: Conduct routine visual and functional inspections to identify wear, damage, or anomalies.

- Lubrication: Maintain proper lubrication by using recommended oils or greases. Regularly check oil levels and quality.

- Cleaning: Keep the gearbox clean and free from debris or contaminants that can accelerate wear.

- Tightening and Alignment: Periodically check and tighten bolts, ensuring proper alignment and reducing vibration.

- Temperature Monitoring: Monitor operating temperatures to prevent overheating, which can lead to premature wear.

- Vibration Analysis: Implement vibration analysis to detect potential issues and abnormal wear patterns.

- Seal Inspection: Inspect seals for leaks and damage, as proper sealing prevents contaminants from entering the gearbox.

- Replacement of Worn Parts: Replace worn or damaged components promptly to prevent further deterioration.

- Gear Tooth Inspection: Regularly assess gear tooth condition and contact patterns to detect wear and misalignment.

- Professional Maintenance: Engage qualified technicians for more in-depth inspections, adjustments, and maintenance.

By adhering to these maintenance practices, operators can extend the lifespan of spiral bevel gearboxes, ensure optimal performance, and minimize the risk of unexpected failures.

Advantages of Using Spiral Bevel Gearboxes in Industrial Applications

Spiral bevel gearboxes offer several advantages when used in industrial applications:

- High Efficiency: Spiral bevel gearboxes have high efficiency due to the smooth and gradual meshing of their angled teeth. This reduces friction and power loss during gear operation.

- Robust and Durable: The design of spiral bevel gears provides robustness and durability, allowing them to handle heavy loads and high torque without premature wear.

- Compact Design: Spiral bevel gearboxes have a compact and space-saving design, making them suitable for applications with limited installation space.

- Smooth Operation: The gradual tooth engagement of spiral bevel gears results in smoother and quieter operation compared to straight bevel gears, minimizing noise and vibration.

- Direction Changes: Spiral bevel gearboxes are ideal for applications requiring changes in the direction of power transmission due to their intersecting shafts at right angles.

- High Torque Transmission: The larger contact area of the spiral bevel gear teeth allows for efficient and reliable transmission of high torque, making them suitable for heavy-duty applications.

- Reliable Power Transmission: Spiral bevel gearboxes ensure accurate and consistent power transmission between intersecting shafts, reducing the risk of gear slippage or misalignment.

- Wide Range of Applications: Spiral bevel gearboxes find use in a variety of industrial applications, including automotive, aerospace, mining, construction, and manufacturing.

- Customization: Manufacturers can customize spiral bevel gearboxes to meet specific application requirements, such as gear ratios, input and output shaft sizes, and mounting options.

Overall, the advantages of spiral bevel gearboxes make them a preferred choice in industrial settings where efficient, reliable, and precise power transmission is essential.

editor by CX 2023-09-05

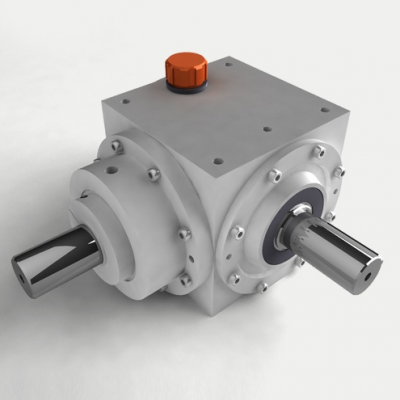

China Good quality Manufacturer Provides K Series 127 Spiral Bevel Gear Reducer K/Ka/Kf/Kaf127 Multi-Stage Variable Speed Gearbox gearbox drive shaft

Product Description

Product Description

-K Series Helical Bevel Gearbox

K series gear reducer, manufactured according to international technical requirements, has a high scientific and technological content; Space saving, reliable and durable, high overload capacity, power up to 132KW; Low energy consumption, superior performance, reducer efficiency up to 95%

It is designed and manufactured on the basis of module combination system. There are a lot of motor combinations, installation forms and structural schemes. The transmission ratio is classified carefully to meet different operating conditions and realize electromechanical integration.

High transmission efficiency, low energy consumption and superior performance.

Reinforced high rigid cast iron box; The hardened gear is made of high-quality alloy steel. Its surface is carburized, quenched and hardened, and the gear is finely ground. It features stable transmission, low noise, large bearing capacity, low temperature rise, and long service life. Performance and characteristics:

1. The gear is carburized and quenched with high-quality alloy, the hardness of the tooth surface is up to 60 ± 2hrc, and the grinding accuracy of the tooth surface is up to 5-6

2. The computer modification technology is used to pre modify the gear, which greatly improves the bearing capacity of the reducer

3. Complete modular structure design is adopted from the box to the internal gear, which is suitable for large-scale production and flexible selection

4. The standard reducer models are divided according to the form of decreasing torque. Compared with the traditional equal proportion division, they are more in line with customer requirements and avoid power waste

5. It is designed and manufactured by cad/cam to ensure the stability of quality

6. Multiple sealing structures are adopted to prevent oil leakage

7. Multi directional noise reduction measures to ensure the excellent low noise performance of the reducer

8. The installation mode of Liyi products is flexible, which makes it easy for customers to choose K57 reducer, K67 reducer, K77 reducer, K87 reducer, K97 reducer, KA87 reducer, KA97 reducer, KA107 reducer, KA127 reducer

Product Features

1. Input mode: Coupled motor, belted motor, input shaft or connection flange.

2. Output: Right angle

3. Compact structure. Rigid tooth face. Carrying greater torque, high loading capacity.

4.High precision gear, ensuring the unit to operate stably, smooth transmission.

5. Low noise, long lifespan. Large overlap coefficient, abrasion resistant.

Our product line

| Hardness: | Hardened Tooth Surface |

|---|---|

| Installation: | 90 Degree |

| Layout: | Expansion |

| Gear Shape: | Bevel Gear |

| Step: | Single-Step |

| Type: | Gear Reducer |

| Samples: |

US$ 1000/Piece

1 Piece(Min.Order) | |

|---|

Torque and Load Distribution in Spiral Bevel Gearboxes

Spiral bevel gearboxes are designed to efficiently handle torque and distribute loads across their gear teeth. The unique geometry of spiral bevel

Precision Applications of Spiral Bevel Gearboxes

Spiral bevel gearboxes are well-suited for precision applications that require accurate and controlled motion. Here’s how they can be used in precision settings:

1. Automotive Manufacturing: Spiral bevel gearboxes play a critical role in automotive assembly lines, where precision is essential for proper alignment and fit of components. They help in controlling robotic arms, conveyors, and tool movements with high accuracy.

2. Aerospace Industry: In the aerospace sector, precision is paramount. Spiral bevel gearboxes are used in various applications, including aircraft landing gear systems, where they enable controlled and accurate movement during takeoff and landing.

3. Medical Equipment: Medical devices, such as robotic surgical systems and imaging equipment, require precise and reliable motion control. Spiral bevel gearboxes ensure accurate positioning and movement in these critical applications.

4. Semiconductor Manufacturing: The semiconductor industry demands extreme precision for the fabrication of microchips. Spiral bevel gearboxes are used in equipment like lithography machines, ensuring precise alignment and motion during the manufacturing process.

5. Optics and Instrumentation: Precision optics, telescopes, and scientific instruments require accurate adjustments and controlled movement. Spiral bevel gearboxes provide the necessary motion control for alignment and focusing.

6. Laboratory Automation: In research laboratories, spiral bevel gearboxes are utilized in robotic systems and automated equipment to handle delicate tasks with precision.

Thanks to their high-precision capabilities, spiral bevel gearboxes contribute to improved accuracy, repeatability, and reliability in a wide range of applications where precise motion control is critical.

gears contributes to their capability in managing torque and load distribution:

- Interlocking Teeth

Selecting a Spiral Bevel Gearbox: Key Considerations

Choosing the right spiral bevel gearbox for a specific application requires careful evaluation of various factors:

- Load Requirements: Determine the torque and load demands of the application to select a gearbox with an appropriate torque rating.

- Speed Range: Consider the desired speed range and ensure that the gearbox can handle the required speeds without compromising efficiency or durability.

- Environmental Conditions: Evaluate the operating environment, including temperature, humidity, and presence of dust or debris, to select suitable materials and sealing mechanisms.

- Mounting and Space Constraints: Assess available space and mounting requirements to ensure that the gearbox can be properly integrated into the machinery.

- Efficiency and Power Loss: Evaluate the gearbox’s efficiency to minimize energy loss and optimize power transmission.

- Noise and Vibration: Consider noise and vibration levels to ensure smooth and quiet operation, especially in applications where low noise is crucial.

- Maintenance and Serviceability: Choose a gearbox that is easy to maintain and service, with accessible lubrication points and inspection covers.

- Budget: Balance the required features and performance with the available budget for the gearbox.

- Manufacturer Reputation: Select a reputable manufacturer with a history of producing high-quality spiral bevel gearboxes.

By carefully evaluating these factors and collaborating with gearbox experts, you can make an informed decision and select a spiral bevel gearbox that meets the specific needs of your application.

:

Spiral bevel gears have curved teeth that gradually engage and disengage as they rotate. This design allows for smoother contact between the gears, reducing abrupt torque spikes and load shocks. - Multiple Contact Points: The spiral teeth provide multiple contact points along the gear tooth profile. This distributed contact helps spread the load evenly, minimizing concentrated stress points.

- High Tooth Engagement: The meshing of spiral bevel gears involves a significant amount of tooth engagement, ensuring that the load is distributed over a larger area of the gear teeth.

- Optimized Tooth Profile: The tooth profile of spiral bevel gears is designed to maintain consistent contact as the gears rotate. This optimized profile contributes to even load distribution.

- Precision Manufacturing: Spiral bevel gears are manufactured with high precision, ensuring accurate gear tooth profiles and minimal deviations. This precision results in uniform load distribution.

Overall, the interplay of these design features allows spiral bevel gearboxes to effectively manage torque and load distribution, leading to reliable and efficient power transmission.

editor by CX 2023-09-01

China 1 year warranty durable 14-186.7rpm NMRV110 series 7.5-100 ratio worm gear reducer for industrial gearbox design

Warranty: 1 a long time

Applicable Industries: Building Content Shops, Manufacturing Plant, Building works , Energy & Mining

Weight (KG): 40 KG

Personalized assistance: OEM

Gearing Arrangement: Worm

Output Torque: 242-767N.M

Enter Velocity: 1400rpm

Output Pace: fourteen-186.7rpm

Item identify: NMRV Worm Equipment Reducer

Product: NMRV110

Material: aluminum alloy Die casting

Colour: Blue

Kind: Worm Equipment Pace Reducer Gearbox

Good quality: 1 Yr Certain

Gears Design: Metallic Equipment

Motor kind: Suitable

Customization: Assistance Drawing Customization

Port: HangZhou or ZheJiang

Why Pick Us Product Display Merchandise Paramenters

| Product title | NMRV Worm Equipment Reducer |

| Warranty | 1 a long time |

| Applicable Industries | Building Materials Outlets, Manufacturing Plant, Development functions , Energy & Mining |

| Weight (KG) | 40KG |

| Customized help | OEM |

| Gearing Arrangement | Worm |

| Output Torque | 242-767N.M |

| Input Velocity | 1400rpm |

| Output Velocity | 14-186.7rpm |

| Place of Origin | ZHangZhoug, China |

| Brand Title | Jiahuang |

| Model | NMRV110 |

| Material | aluminum alloy Die casting |

| Color | Blue |

| Type | Worm Gear Pace Reducer Gearbox |

| Quality | 1 12 months Assured |

| Gears Type | Metal Equipment |

| Motor variety | Suitable |

| Customization | Support Drawing Customization |

The Different Types of Gearboxes

There are many different types of gearboxes. Some brands have more than one type. In this article, we’ll discuss the planetary gearbox, the worm reduction gearbox, the shaft mounted gearbox, and the one speed gearbox. This article will also help you determine which type of gearbox is best for your vehicle. And don’t worry if you don’t know the terminology yet. We’ll explain each type in detail so that you know what you’re getting yourself into.

Planetary gearbox

Planetary gears have many advantages. The multiple gears in a planetary gearbox mesh simultaneously during operation. As such, they provide high efficiency and transmit high transmittable torque. These gears are widely used in various industries and are resistant to high shock loads and demanding conditions. CZPT is one of the companies that offer planetary gearboxes. Its products do not require special tools for assembly, and its scalable design minimizes safety stock.

Among the numerous benefits of planetary gearing is its compactness and lightweight. As such, it is suitable for wide applications with space and weight constraints. However, to truly appreciate its benefits, it is necessary to understand its mechanisms. Here are some of the most common details about planetary gearing:

The planetary gearbox has two mounted gears: an input shaft and an output shaft. Each gear has multiple teeth that are attached to a carrier and rotate with the input shaft. The carrier is connected to the output shaft. A planetary gear is mounted on both gears via a carrier. The carrier rotates in order to drive the planetary gear. The sun gear is often the input gear. The other gear is called the outer gear.

Planetary gearboxes are highly customizable. The size, mounting, and housing options vary, as do the reduction ratios and input speeds. Different types can be manufactured for different applications and include options such as electrical or mechanical preload. The final design of a planetary gearbox can be highly customized, based on the specifications of the application. By combining engineering excellence and ongoing innovation, planetary gearboxes provide years of trouble-free operation.

A planetary gearbox can be either an electric motor or a manual one. The latter has more features than the former, and can be used in applications where space is an issue. The primary features of a planetary gearbox include its backlash, torque, and ratio. Secondary features include noise, corrosion resistance, and construction. A planetary gearbox is a highly versatile gearbox that can drive anything from simple machinery to advanced electrical systems.

Worm reduction gearbox

The global worm reduction gearbox market report compiles key insights from the industry to help you improve your business strategy. This report will help you create a comprehensive business document that will enhance your company’s competitive edge. To obtain this report, visit our website now! Read our latest report to find out what you can expect from the global worm reduction gearbox market. Alternatively, request a sample copy for more details. Here is a sneak peek of the report:

Worm gears are made with different thread counts and are usually not matched with the CZPT standard. In general, a single thread worm should be used with a single thread worm. Worm gears have either right or left threads, and their thread count will be different as well. This type of gear is used to reduce the speed of a rotating shaft. The speed reduction ratio will be about 50 percent if the worms have the same thread count as the CZPT gears.

The standard gear set transfers power at the peak load point of a tooth, called the pitchline. The worm gear moves slowly against the wheel’s metal surface. The worm gear is also more complex than the standard gear because the worm is sliding rather than rolling. Worm gears are hard to lubricate. Moreover, the sliding contact between the gear and worm increases the complexity of the gear set. They can be a great solution for applications where noise is a significant factor.

The axial pitch and circular pitch of the worm are equal. The ratio of these two indices determines the speed of transmission. For a worm reduction gearbox to work, the axial pitch and the circular pitch must match. The pitch angle of a worm can either be left-handed or right-handed. The lead of a worm is the distance one thread travels in one revolution. The lead angle is the angle tangent to the thread helix of the cylinder’s pitch. When a worm mesh is reversed, the majority of the mesh will be on the receding arc.

Worm gears generate more heat than their counterparts, so it is important to choose a worm reduction gearbox carefully. You will want to choose the material and amount of lubricating oil carefully. Worm gears are generally made of tin bronze. The paired worms are hardened to HRC45-55. In general, they are durable, lasting up to ten years. But they will wear out – and they wear out – so you may want to consider some other factors.

Shaft-mounted gearbox

Shaft-mounted gearboxes are designed for a variety of mining and quarry applications. Their high reliability and low maintenance make them an excellent choice in these types of applications. Shaft-mounted gearboxes also feature an optional backstop device that prevents the unit from rotating in one direction. This makes them an excellent choice for applications where alignment accuracy is an issue. Here are some of the benefits of using a shaft-mounted gearbox:

Shaft-mounted gearboxes are typically constructed of aluminium, and come in sizes ranging from 050 to 125. They feature a variety of reduction ratios and ensure optimum efficiency in all operating conditions. New S series sizes, 140 and 150, extend the application range of shaft-mounted gearmotors. They are both backed by a two-year warranty. For even greater peace of mind, Shaft-mounted gearboxes are available with a range of warranty options.

The most common applications for a Shaft-mounted gearbox include traction-driven applications where a low-speed shaft is required for operation. They also are suitable for applications without a foundation, where the motor is mounted next to the reducer. To prevent the gear drive from rotating, a torque arm is attached between the motor and the shaft. Small-sized shaft-mounted gear drives are usually made without motor mount kits, which can make them an excellent choice for conveying light loads.

Another important feature of a Shaft-mounted gearbox is its mounting position. The reduced motion through the drive is redirected through the shaft, creating additional forces. These additional forces can affect the performance of the gearbox, causing vibrations and noise. Consequently, it is important to replace worn or damaged belts on a regular basis. Further, shaft-mounted gearboxes can be affected by problems with other components and amplify vibrations.

1 speed gearbox

CZPT Group Components produces one speed gearboxes. These transmissions are produced in the CZPT Group’s Kassel plant. They are compact and robust, and are designed for easy integration. The Bosch Rexroth GD1 one-speed gearbox is easy to install horizontally or vertically. The Plug and Drive system integrates the gearbox with the existing cooling system. There are many other benefits to this gearbox.

With an ID.3 electric drive motor, the maximum torque is delivered at 16,000 rpm. This single-speed transmission offers high power density and excellent noise-reduction, making it ideal for electric vehicles. The e-drive motor is extremely quiet and requires precision manufacturing. The e-drive motor also enables a wide range of driving conditions. It can reverse when needed, and reaches its maximum speed at 16,000.

The single-speed gearbox is a standard feature on most electric vehicles. Some electric vehicles, such as the Porsche Taycan, will be equipped with a two-speed gearbox. This gearbox offers more top speed and range, but it is more complex than a standard single-speed gearbox. CZPT doesn’t need to add complexity to its electric vehicles. After all, a 355 horsepower family wagon is not likely to need a dual-speed gearbox.

In addition to simplifying the transmission, the patent claims also address improvements in structural design. Fig. 5 shows a schematic representation of a transmission 50′, wherein gear sets Z1 and Z4 are exchanged between partial transmissions. This switch matrix also reflects the synchronized gears and lastshelf gears. Hydraulically betatigte Lamellenkupplungen (HBA) also form a last-shelf gear.

Another advantage of the patent claim is that it offers numerous functional freedoms, which is especially valuable in the design of an automobile. One of the patent claims identifies a tosatzlicher middle gear that allows a driver to switch between second and third gears, with a single gearbox. In a conventional one-speed transmission, the tosatzlicher middle gear is attached to the second and first part gearbox. The latter has a second and third gear.

editor by czh

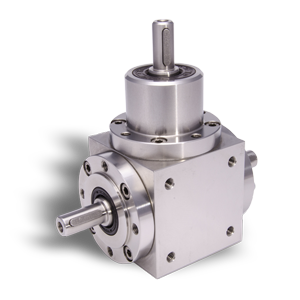

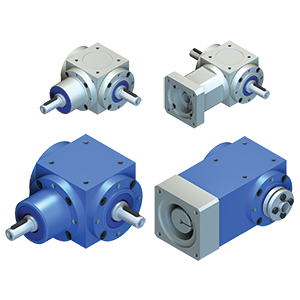

China wholesaler T Series 90 degree right angle gearbox speed reducer power transmission drive gearbox 90 degree drive gear box wholesaler

Applicable Industries: Building Material Shops

Gearing Arrangement: Bevel / Miter

Output Torque: Up to 3378Nm

Input Speed: 750-1500rpm

Output Speed: 3~1450r/min

Certification: ISO9001-2008

Mount Position: Foot Mounted

Bearing: C&U

gear precision grade: din 4

Packaging Details: Standard wooden case

Port: HangZhou Port, ZheJiang Port

T Series comer 90 degree right angle gearbox speed reducer power transmission drive comer gearbox

Advantage:

-Self-locking ability-Can be driven directly by motor or other power or manual-Can be customized according user’s demand-Compact configuration, small size, lightweight-Convenient installation, flexible operation-High reliability and stability-Long service life-More connection form etc.Screw jak is applied to all fields for lifting or pulling, such as Aircraft maintenance platform, Solar plate, machinery, metallurgy, water conservancy, medical treatment, chemical industry, Top grade 358286A1 drive shaft Suitable for Case ih heavy construction machinery parts culture and hygienist etc.

Specifications:1.Tseries sprial bevel gear reducer with various types are standardized2.all ratio of 1:1,1.5:1;2:1;2.5:1;3:1;4:1;and 5:1 are actual ones,3.average efficiency is 98%.

3.average efficiency is 98%.

Product Name

T series Spiral Bevel Gearbox

model no.

T2, T4, T6, T7, T8, Durable Using 0.06-15W 1400RPM Speed Reducer Pull Back Gearbox Worm Gearbox T10, T12, T16, T20, T25

Ratio

1:1, 1.5:1, 2:1, 2.5:1,3:1,4:1,5:1

gear Material

high grade synthetic CZPT 50CrMnT

Gear Processing

Grinding finish by HOFLER Grinding Machines, Precision grade : DIN 4

spindle

high purity steel alloy 40Cr piece

Noise Test

Bellow 65dB

Warranty

1 year

Certifications

Trade Shows

Packaging & Advance 1000-2500rpm speed marine gearbox 300 ShippingPacking Details : Standard carton/Pallet/Standard wooden case

Delivery Details : 15-30 working days upon payment

Company Information

other series product

Precision Planetary gearbox

Robot RV gearbox speed reducer

Custom made Non-standard Gearbox

UDL Series Variator

PYZ Series Helical Tooth Shaft Mounted Reducer

8000 Series Cycloidal Reducer

SLT Series Spiral Bevel Gearbox

SLSWL Series Worm Screw Jack

SLP Series Planetary Reducer

SLH/SLB Series High Power Reducer

NMRV Series Worm Reducer

BKM Series Helical-hypoid Reducer

SLRC Series Helical Reducer

SLSMR Series Shaft Mounted Reducer

SLXG Series Shaft Mounted Reducer

X/B Series Cycloidal Reducer

SLR/SLF/SLK/SLS Series Helical Reducer

Related Products

Contact

Types of Gearboxes

There are several types of gearboxes. Some are known as helical gear reducers, while others are called planetary gearboxes. The article also discusses Continuously Variable Transmission (CVT) and helical gear reducer. If you are interested in purchasing a new gearbox, make sure to read our articles on these different types. If you are confused, consider reading our articles on planetary gearboxes and helical gear reducers.

planetary gearbox

The planetary gearbox has several advantages. Its compact design and light weight allows it to transmit high torques while remaining quiet. The gears are connected to one another through a carrier, which is typically fixed and helps transmit torques to the output shaft. Its planetary structure arrangement also reduces backlash and provides high rigidity, which is important for quick start and stop cycles and rotational direction change. Depending on the design and performance desired, planetary gearboxes are categorized into three main types:

The type of planetary gears used in a given application determines the overall cost of the unit. Manufacturers offer a range of prices, and they can help you determine which gearbox is right for your needs. You should also ask a manufacturer for the cost of a planetary gearbox. By asking about price and specs, you can avoid wasting money and time on a planetary gearbox that does not perform up to its potential.

A planetary gearbox is probably installed in your new car’s automatic transmission. For more information, consult your owner’s manual or call the dealer’s service department. This type of gearbox is more complex than other types of gearboxes, so if you don’t know much about them, do an internet search for “planetary gearbox.”

The teeth of a planetary gearbox are formed by the stepping motion of two gears: the sun gear and the inner ring. The sun gear is the input, while the planetary gears rotate around the sun gear. Their ratio depends on the number of teeth and the space between the planets. If you have a 24 tooth sun gear, the planetary gears’ ratio will be -3/2. The sun gear is also attached to the axle.

Another advantage of a planetary gear system is that it can generate high torques. The load is shared among multiple planet gears. This makes the gears more resilient to damage. A planetary gearbox can be as high as 332,000 Nm, and can be used in vehicles and industrial applications requiring medium to high torque. A planetary gear system is a great alternative to a traditional transmission. So, how does it work?

helical gearbox

The main difference between the helical gearbox and the spur gear is the center distance between the teeth. The helical gearbox has a larger pitch circle than the spur gear and thus requires a radial module. In addition, the two types of gears can only be made with the same tooth-cutting tool as the spur gear. However, the helical gearbox is more efficient in terms of production costs.

The helical gearbox is a low-power consumption, compact type of gearbox that is used for a wide range of industrial applications. They are highly durable and withstand high loads with utmost efficiency. The helical gearbox can be manufactured in cast steel and iron for small and medium units. This type of gearbox is also commonly used for crushers, conveyors, coolers, and other applications that need low power.

The helical gear has many advantages over the spur gear. It produces less noise. It has less friction and is less likely to wear out. It is also quieter than spur gears. This is because multiple teeth are in mesh. Because the teeth are in mesh, the load is distributed over a larger area, resulting in a smoother transition between gears. The reduction in noise and vibration reduces the risk of damaging the gear.

The helical gear’s axial excitation force is obtained using a linearized equation of motion in the rotational direction. The damping coefficient of the equation is 0.07. The helical gear is made up of a steel shaft with a diameter of 20 mm and a 5 mm thick aluminum plate. The stiffness of the bearing is 6.84 x 107 N/m. The damping force of the plate is 2,040 kg/m2/s.

The worm gearbox has a better efficiency ratio than the helical one, but it is less efficient in low-ratio applications. In general, worm gearboxes are more efficient than helical gearboxes, although there are some exceptions to this rule. A helical gearbox is better for applications that require high torque. It may also be more economical in the long run. If you are considering a helical gearbox, consider the advantages it has over worm gearboxes.

helical gear reducer

A helical gear reducer for a machine’s gearbox is an integral component of the drive system. This unit amplifies torque and controls speed and, therefore, compliments the engine by rotating slower than the engine’s input shaft. A helical gear reducer is a compact gearbox component that is used in industrial applications. A variety of sizes is available to suit various machine configurations. The following sections will discuss some of the different types available.

Designed by experts and engineers, a helical gear reducer is a surprisingly small and light gear that satisfies the needs of many machine applications. It features a large transmission torque, a low starting and running speed, and a fine classification of transmission ratios. A helical gear reducer is lightweight and easily connected to other gears, and it features a high technical content.

In order to avoid errors and poor performance, regular maintenance is a must. The proper lubrication of the gear reducer can minimize failures, errors, and poor performance. Every gear reducer manufacturer sells a suitable lubricant, which must match the properties of the machine’s drive mechanism. It is also advisable to check the lubrication regularly to avoid any deterioration of the unit’s performance.

While the worm gearbox may be better for applications where torque is high, the helical gear reducer offers greater efficiency at lower cost. Although worm gearboxes may be cheaper initially, they are less effective at higher ratios. Even if the worm gear is more expensive to buy, it still offers 94% efficiency, which makes it more cost-effective. There are some significant advantages to both types of gearboxes.

The main advantage of a helical gear reducer over a spur gear is its smoother operation. Unlike spur gears, which have teeth that are straight, helical gears have angled teeth that gradually engage with each other. This helps ensure that the gear does not grind or make excessive noise when it turns. Additionally, they are less commonly used in automation and precision machinery. They are often used in industrial applications.

Continuously variable transmission

A Continuously Variable Transmission (CVT) is an automatic transmission that can run through a vast number of gears. Unlike a standard automatic transmission, it can run at any speed, even at a low rev. The CVT is also capable of running at infinitely low gears. Its basic function is to provide different torque ratios to the engine. In addition to delivering power, CVTs have other benefits.

One of the major advantages of a CVT is its simplicity. Its simplicity translates into fewer moving parts, which means less maintenance. The CVT’s simplicity also means that it can handle a wide variety of different types of road conditions and driving styles. In addition to being a great alternative to a traditional automatic transmission, CVTs can be used on many other types of vehicles, including tractors, snowmobiles, motor scooters, and power tools.

A CVT is much smoother than a conventional automatic transmission. It never has to hunt for a gear. It also responds well to throttle inputs and speed changes. Both of these technologies are available on many modern vehicles, including the Nissan Rogue and Mazda CX-5. It’s important to note that each of these transmissions has its pros and cons. So, if you’re looking for a car with a CVT, make sure to read the reviews. They’ll help you decide which transmission is right for you.

Another advantage of a CVT is its fuel efficiency. Many cars now feature CVTs, and they’re becoming increasingly popular with automakers. In addition to fuel efficiency, most cars with CVTs also have a smoother ride. There’s no more sudden downshifts or gear hunting. This makes driving a lot easier. And, the added benefits of smoother driving make CVTs the ideal choice for many drivers.

Although a CVT is more common among Japanese car manufacturers, you’ll find CVTs on European car models as well. The Mercedes-Benz A-Class, B-Class, and Megane are some examples of vehicles that use this technology. Before making a decision, consider the reliability of the model in question. Consumer Reports is a good resource for this. It also offers a history of use and reliability for every type of car, including the Honda Accord.

China Custom R series agri gear reducer reducer motor gearmotor reducing machine gear box speed high rpm gearbox with motor 380V 50HZ 60HZ 4P near me manufacturer

Warranty: 1 years, 18 Months

Applicable Industries: Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company

Weight (KG): 35

Customized support: OEM, ODM, Supply FJ80 HDJ80 Car Auto Parts 333686571 Gearbox Synchronizer Ring OEM 33368-6571 OBM

Gearing Arrangement: Helical

Output Torque: 800~100000N.m

Input Speed: 1400rpm

Output Speed: 14-280rpm

Product name: 5hp helical geared motor

Ratio: 7.5~100

Mount Position: Foot Mounted

Bearing: LYC

Heat treatment: High Frequency Quenching

Certification: ISO9001-2008

Application: Packing Machine

Color: Customer Request

Packing: Wooden Case

Packaging Details: Wooden boxes , Cantons packed in 1 pallet

Product Overview R series HELICAL GEARBOXSLR helical reducer has the features of high versatility,good combination and heavy loading capability, along with other merits such as easy to attain various transmission ratios, high efficiency, low vibrationand high permissible axis radial load. This series can not only be combined with various kinds of reducers and variators and meet the requirements, but also beadvantage of localization of related transmission equipment. FEATURES AT A GLANCE 1) Output speed: 0.6~1,571r/min2) Output torque: up to 18,000N.m3) Motor power: 0.18~160kW4) Mounted form: foot-mounted and flange-mounted mounting Right elevation Left elevation Front elevation PRODUCT SPECIFICATIONS NoItemDataProduct NameSLR Series Rigid Tooth helical reducer37.5KWGear Material20CrMnTi2.8 M3Case MaterialHT250125TonShaft Material20CrMnTi96kNGear ProcessingGrinding finish by HOFLER Grinding Machines96kNColorCustomized60kNNoise TestBellow 65dB6750ml8Max. torque500N.m PRODUCT CONFIGURATION CHANGCHAI high power engine Imported CZPT control valve Japan Shimadzu hydraulic motor Company Profile About usEstablished in 1985, CZPT TRANSMISSION MACHINERY CO., LTD is a high and new technology enterprise engaging in research, develop and manufacture for reducer & speed variator, 1 of the director member of China Reducer Association of China General Machinery.It covers more than 40,000 square meters, has more than 400 staff , 20% of whom are technicians, equipped with more than 300 sets the most advanced accurate numerical control equipment, high quality HangZhou Great transmission HOLLOW PIN CHAINS double pitch biglarge rollers conveyor transmission chain including German HOFLER forming gear grinding machine to improve quality. Quality Control Related Product Project in Thailand Project in India Project in Russia FAQ 1.Payment Term: TT, L/C2.Delivery time: about 30 days from receive payment. 3.We accept customized products as per your special requirement.4.Xihu (West Lake) Dis.lines for the Selection:Usually we can select 1 machine which is suitable for you with some informations from you,such asratio/motor speed/mounting dimension/ out torque etc. 5.If the minimum order amount is in excess of $10000, there are preferential.Q1: What information should I tell you to confirm the product?A:Model/Size, Transmission Ratio, Shaft directions & Order quantity.Q2: What can i do if I don’t know which 1 I need?A:Dont worry, Send as much information as you can, our team will help you find the right 1 you are looking for.Q3: What is your product warranty period?A:We offer 1 year warranty since the vessel departure date left China.Q4: Are you trading company or manufacturer ?A: We are factory.Q5: How long is your delivery time?A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according toquantity.Q6: Do you provide samples ? is it free or extra ?A: Yes, we could offer the sample for free charge but do not pay the cost of freight.Q7: What is your terms of payment ?A: Payment=1000USD, 30% T/T in advance ,balance before shippment.If you have another question, pls feel free to contact us as below:

Key Market Insights Related to Worm Reduction Gearboxes

A gearbox is a mechanical device that allows you to shift between different speeds or gears. It does so by using one or more clutches. Some gearboxes are single-clutch, while others use two clutches. You can even find a gearbox with closed bladders. These are also known as dual clutches and can shift gears more quickly than other types. Performance cars are designed with these types of gearboxes.

Backlash measurement

Gearbox backlash is a common component that can cause noise or other problems in a car. In fact, the beats and sets of gears in a gearbox are often excited by the oscillations of the engine torque. Noise from gearboxes can be significant, particularly in secondary shafts that engage output gears with a differential ring. To measure backlash and other dimensional variations, an operator can periodically take the output shaft’s motion and compare it to a known value.

A comparator measures the angular displacement between two gears and displays the results. In one method, a secondary shaft is disengaged from the gearbox and a control gauge is attached to its end. A threaded pin is used to secure the differential crown to the secondary shaft. The output pinion is engaged with the differential ring with the aid of a control gauge. The angular displacement of the secondary shaft is then measured by using the dimensions of the output pinion.

Backlash measurements are important to ensure the smooth rotation of meshed gears. There are various types of backlash, which are classified according to the type of gear used. The first type is called circumferential backlash, which is the length of the pitch circle around which the gear rotates to make contact. The second type, angular backlash, is defined as the maximum angle of movement between two meshed gears, which allows the other gear to move when the other gear is stationary.

The backlash measurement for gearbox is one of the most important tests in the manufacturing process. It is a criterion of tightness or looseness in a gear set, and too much backlash can jam a gear set, causing it to interface on the weaker part of its gear teeth. When backlash is too tight, it can lead to gears jamming under thermal expansion. On the other hand, too much backlash is bad for performance.

Worm reduction gearboxes

Worm reduction gearboxes are used in the production of many different kinds of machines, including steel and power plants. They are also used extensively in the sugar and paper industries. The company is constantly aiming to improve their products and services to remain competitive in the global marketplace. The following is a summary of key market insights related to this type of gearbox. This report will help you make informed business decisions. Read on to learn more about the advantages of this type of gearbox.

Compared to conventional gear sets, worm reduction gearboxes have few disadvantages. Worm gear reducers are commonly available and manufacturers have standardized their mounting dimensions. There are no unique requirements for shaft length, height, and diameter. This makes them a very versatile piece of equipment. You can choose to use one or combine several worm gear reducers to fit your specific application. And because they have standardized ratios, you will not have to worry about matching up multiple gears and determining which ones fit.

One of the primary disadvantages of worm reduction gearboxes is their reduced efficiency. Worm reduction gearboxes usually have a maximum reduction ratio of five to sixty. The higher-performance hypoid gears have an output speed of around ten to twelve revolutions. In these cases, the reduced ratios are lower than those with conventional gearing. Worm reduction gearboxes are generally more efficient than hypoid gear sets, but they still have a low efficiency.

The worm reduction gearboxes have many advantages over traditional gearboxes. They are simple to maintain and can work in a range of different applications. Because of their reduced speed, they are perfect for conveyor belt systems.

Worm reduction gearboxes with closed bladders

The worm and the gear mesh with each other in a combination of sliding and rolling movements. This sliding action is dominant at high reduction ratios, and the worm and gear are made of dissimilar metals, which results in friction and heat. This limits the efficiency of worm gears to around thirty to fifty percent. A softer material for the gear can be used to absorb shock loads during operation.

A normal gear changes its output independently once a sufficient load is applied. However, the backstop complicates the gear configuration. Worm gears require lubrication because of the sliding wear and friction introduced during movement. A common gear arrangement moves power at the peak load section of a tooth. The sliding happens at low speeds on either side of the apex and occurs at a low velocity.

Single-reduction gearboxes with closed bladders may not require a drain plug. The reservoir for a worm gear reducer is designed so that the gears are in constant contact with lubricant. However, the closed bladders will cause the worm gear to wear out more quickly, which can cause premature wear and increased energy consumption. In this case, the gears can be replaced.

Worm gears are commonly used for speed reduction applications. Unlike conventional gear sets, worm gears have higher reduction ratios. The number of gear teeth in the worm reduces the speed of a particular motor by a substantial amount. This makes worm gears an attractive option for hoisting applications. In addition to their increased efficiency, worm gears are compact and less prone to mechanical failure.

Shaft arrangement of a gearbox

The ray-diagram of a gearbox shows the arrangement of gears in the various shafts of the transmission. It also shows how the transmission produces different output speeds from a single speed. The ratios that represent the speed of the spindle are called the step ratio and the progression. A French engineer named Charles Renard introduced five basic series of gearbox speeds. The first series is the gear ratio and the second series is the reverse gear ratio.

The layout of the gear axle system in a gearbox relates to its speed ratio. In general, the speed ratio and the centre distance are coupled by the gear axles to form an efficient transmission. Other factors that may affect the layout of the gear axles include space constraints, the axial dimension, and the stressed equilibrium. In October 2009, the inventors of a manual transmission disclosed the invention as No. 2. These gears can be used to realize accurate gear ratios.

The input shaft 4 in the gear housing 16 is arranged radially with the gearbox output shaft. It drives the lubricating oil pump 2. The pump draws oil from a filter and container 21. It then delivers the lubricating oil into the rotation chamber 3. The chamber extends along the longitudinal direction of the gearbox input shaft 4, and it expands to its maximum diameter. The chamber is relatively large, due to a detent 43.

Different configurations of gearboxes are based on their mounting. The mounting of gearboxes to the driven equipment dictates the arrangement of shafts in the gearbox. In certain cases, space constraints also affect the shaft arrangement. This is the reason why the input shaft in a gearbox may be offset horizontally or vertically. However, the input shaft is hollow, so that it can be connected to lead through lines or clamping sets.

Mounting of a gearbox

In the mathematical model of a gearbox, the mounting is defined as the relationship between the input and output shafts. This is also known as the Rotational Mount. It is one of the most popular types of models used for drivetrain simulation. This model is a simplified form of the rotational mount, which can be used in a reduced drivetrain model with physical parameters. The parameters that define the rotational mount are the TaiOut and TaiIn of the input and output shaft. The Rotational Mount is used to model torques between these two shafts.

The proper mounting of a gearbox is crucial for the performance of the machine. If the gearbox is not aligned properly, it may result in excessive stress and wear. It may also result in malfunctioning of the associated device. Improper mounting also increases the chances of the gearbox overheating or failing to transfer torque. It is essential to ensure that you check the mounting tolerance of a gearbox before installing it in a vehicle.

in Salem India sales price shop near me near me shop factory supplier RV Series Gear Gearbox Speed Reducer manufacturer best Cost Custom Cheap wholesaler

“We are often serving our buyers with our greatest goods.” With a lot of years’ knowledge in this line, we will be trusted by our positive aspects in aggressive price tag, one-time shipping, prompt reaction, on-hand engineering help and excellent after-revenue providers.Furthermore, all our manufacturing techniques are in compliance with ISO9001 requirements. The group is targeted on generating all assortment of normal roller chains and sprockets, gears & gearboxes, this kind of as conveyor chain & sprockets , stainless metal chain, agricultural chain and has not just bought its products all over china, but also bought far more than sixty five% goods to oversees, which includes Europe, The usa, South-east Asia, and it also has set up storage logistics in places like Europe.

RV Collection EPT EPTT Pace EPTT

RV Sequence

IncXiHu (West EPT) Dis.Hu (West EPT) Dis. RV / NMRV / NRV.

Main Characteristic of RV Sequence Worm EPTT

RV sequence worm EPT EPTT is a new-technology solution deveXiHu (West EPT) Dis.Hu (West EPT) Dis.ed by EPTT on the basis of perfecting WJ sequence merchandise with a compromise of EPTd EPT each at house and abroad.

one. EPT-good quality EPT alloy, ligEPTT in weigEPTT and non-rusting.

two. Large in output torque.

three. EPT running and reduced sound,resilient in dreadful circumstances.

four. EPT radiation performance.

five. Very good-seeking look, sturdy in provider lifestyle and modest quantity.

six. Ideal for omnibearing set up.

Main EPTs of RV Collection Worm EPTT

one. EPT: die-solid EPT alloy(body size: 571 to 090), cast iron(frame dimensions: one hundred ten to 150).

2. Worm: 20Crm, carbonization quencher warmth therapy can make the surface hardness of worm EPTs up to 56-sixty two EPTX, retain carbonization layer’s thickness amongst .3 and .5mm right after precise grinding.

3. Worm Wheel: wearable stannum bronze alloy.

| Speed RATIO | seven.five~a hundred |

| OUTPUT TORQUE | lt1050NM |

| IN EPTT | .09-11KW |

| MOUNTING Kind | FOOT-MOUNTED FLANGE-MOUNTED |

| When doing work, wonderful load ability, secure working, minimal noise with substantial efficiency. | |||||||

| EPT Box’s Utilization Area | |||||||

| 1 | EPTlurgy | eleven | Agitator | ||||

| 2 | Mine | 12 | Rotary weeder | ||||

| three | EPTT | thirteen | EPTlurgy | ||||

| 4 | Strength | fourteen | EPTT | ||||

| 5 | EPTT | fifteen | EPT sector | ||||

| six | Drinking water Conserbancy | 16 | Air EPTT | ||||

| 7 | EPTcco | 17 | Crusher | ||||

| eight | Health-related | 18 | EPTs | ||||

| 9 | EPTT | 19 | Electronics | ||||

| ten | EPTT industry | twenty | EPT indutry | ||||

| … | … | ||||||

| EPTT | .06kw | .09kw | .12kw | .18kw | .25kw | .37kw | .55kw |

| .75kw | one.1kw | 1.5kw | 2.2kw | 3kw | 4kw | 5.5kw | |

| seven.5kw | 11kw | 15kw | |||||

| Torque | two.6N.m-3000N.m | ||||||

| Ratio | seven.five-100, the double EPTT is more | ||||||

| EPTT | EPTT, Silver or as customers’ need | ||||||

| EPT | Iron or Aluminium | ||||||

| EPTT | EPTT with Plywood Case or as clients’ prerequisite | ||||||

| Type | RV571 | RV030 | RV040 | RV050 | RV063 | RV075 | RV090 |

| Fat | .7kg | one.3kg | two.3kg | three.5kg | 6.2kg | 9kg | 13kg |

| Kind | RV110 | RV130 | RV150 | ||||

| Fat | 35kg | 60kg | 84kg | ||||

| Mounting Techniques | Foot Installation | Flange Set up | |||||

| For numerous mortor or double input/output shafts can be equipped | |||||||

Product picture:

Composition:

Certification:

EPTT amp Shipping and delivery:

Our organization :

EPTT reg was started in 1982, which has much more than 36 many years in R amp D and production of EPTTes, EPTs, shaft, motor and spare components.

We can provide the proper answer for uncountable programs. Our products are widely utilised in the ranges of metallurgical, steel, mining, pulp and paper, suXiHu (West EPT) Dis.Hu (West EPT) Dis. and alcohol industry and different other kinds of EPTTs with a powerful presence in the worldwide market.

EPTT reg has turn out to be a reputable supplier, in a position to supply higher quality EPTTes.With 36 several years encounter, we assure you the utmost reliability and security for the two merchandise and companies.

Buyer going to:

FAQ:

one.Q:What varieties of EPTT can you create for us?

A:Major products of our firm: UDL series pace variator,RV collection worm EPT EPTT, ATA collection shaft mounted EPTT, X,B collection EPT EPTT,

P series planetary EPTT and R, S, K, and F collection helical-tooth EPTT, a lot more

than one hundred designs and thousands of technical specs

2.Q:Can you make as for each custom drawing?

A: Sure, we supply EPT provider for buyers.

3.Q:What is your terms of payment ?

A: 30% Advance payment by T/T after signing the agreement.70% before shipping and delivery

four.Q:What is your MOQ?

A: one Set

Contact:

Welcome you contace me if you are intrigued in our product.

Our staff will help any need to have you migEPTT have.

in Aligarh India sales price shop near me near me shop factory supplier Electric Motor Speed Reducer K Series Bevel Gear with Hallow Shaft Mouted for Mining Equipment manufacturer best Cost Custom Cheap wholesaler

Our goods are used in several fields. Far more importantly, we make special elements according to supplied drawings/samples and warmly welcome OEM inquiries. Meanwhile, our items are created in accordance to higher good quality expectations, and complying with the worldwide superior standard requirements.

Solution Description

K sequence EPTT EPTT/ EPTT motor EPTT electric motor with reduction EPTT micro cycloidal EPTT EPTT EPTT box

SLK series EPTT is one particular variety of Helical EPTTl kind EPTT , Higher-stainless forged iron case . ,it is designed primarily based on modularization , which carry several difference types of mixtures ,mounting types ,and framework patterns .The detail classification of ratio can meet up with a variety of of doing work situation .Higher EPTT effectiveness ,Low strength usage, superior performance . The difficult tooth area EPTT use the high good quality alloy metal , the method of carburizing and quenching, grinding ,which give it adhere to people : Stable EPTT , lower sounds and temperature ,large loading ,EPTT working lifestyle. which widely use for business gear of metallurgy ,Constructing EPTT , Chemical , EPTT , Oil, Transportation , Papermaking , SuXiHu (West Lake) Dis.Hu (West Lake) Dis. generating , engineering EPTTs ,and so forth

Specifications:

1) Output speed: .6~1,571r/min

two) Output torque: up to 21700N.m

3) EPTT EPTT: .12~200kW

4) Mounted form: foot-mounted and flange-mounted mounting

| Product Identify | SLK Series Rigid Tooth helical EPTTl EPTT |

| Equipment EPTT | 20CrMnTi |

| Situation EPTT | EPTT250 |

| Shaft EPTT | 20CrMnTi |

| Gear Processing | Grinding end by HOFLER Grinding EPTTs |

| Color | Custom-made |

| Sound Check | sixty five~70dB |

| Effectiveness | 94%~98% (relies upon on the EPTT phase) |

| Lubricating oil | Shell Omala synthetic oil or EPTTral oil , or equivalent brand |

| Heat treatment | tempering, cementiting, quenching,and so forth. |

| Brand name of bearings | C ampU bearing, ZWZ,LYC, EPTB, SKF,NSK and so on |

| Brand of oil seal | NAK or other brand name |

| Temp. increase (MAX) | 40 deg |

| Temp. rise (Oil)(MAX) | 50 deg |

| Vibration | le20 microm |

Firm info

EstabEPTTd in 1985, EPTT EPTT EPTTRY CO., LTD is a substantial and new EPTT EPTTrprise engaging in analysis, deveXiHu (West Lake) Dis.Hu (West Lake) Dis. and manufacture for EPTT amp velocity variator, one of the director member of EPTT EPTT Association of EPTT EPTT EPTTry.

It covers more than forty,000 square meters, has far more than 400 workers , twenty% of whom are professionals, equipped with a lot more than three hundred sets the most EPTT exact numerical manage gear, incXiHu (West Lake) Dis.Hu (West Lake) Dis. German HOFLER forming EPTT grinding EPTT to improve high quality.

set up much more than 30 national sales branches to provide our consumers in time and thoroughly.

Our merchandise also exported to much more than 30 international locations principal in Europe, Asia The united states, and Africa, with substantial reputation.

EPTT management

EPTT ampDelivery

EPTT Particulars: StXiHu (West Lake) Dis.Hu (West Lake) Dis.rd carton/Pallet/StXiHu (West Lake) Dis.Hu (West Lake) Dis.rd wood circumstance

Delivery Particulars : fifteen-thirty working daEPTTupon payment

Associated Product

| EPTT Planetary EPTT | Robot RV EPTT pace EPTT |

| Custom created Non-stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd EPTT | UDL Series Variator |

| PYZ Series Helical Tooth Shaft Mounted EPTT | 8000 Collection Cycloidal EPTT |

| SLT Series Spiral EPTTl EPTT | SLSWL Sequence Worm Screw Jack |

| SLP Collection Planetary EPTT | SLH/SLB Collection High EPTT EPTT |

| NMRV Sequence Worm EPTT | BKM Collection Helical-hypoid EPTT |

| SLRC Collection Helical EPTT | SLEPTR Collection Shaft Mounted EPTT |

| SLXG Series Shaft Mounted EPTT | X/B Collection Cycloidal EPTT |

| SLR/SEPTT/SLK/SLS Sequence Helical EPTT | AC/DC EPTT |

Main merchandise list: sixteen collection incXiHu (West Lake) Dis.Hu (West Lake) Dis. SLR/SLS/SLK/SEPTT series tough tooth flank EPTT EPTT , SLRC series aluminium circumstance helical EPTT EPTTs,SLHSLB sequence higher EPTT velocity EPTT, SLP sequence planetary velocity EPTT, X/B sequence cycloidal EPTT, SLXG series shaft-mounted EPTT box, SLSWL collection worm screw jack, SLT collection helical cone EPTT box, entirely a lot more than 10,000 ratios, various specification make us at the head of domestic EPTT market, widely serve the mechanical EPTT subject of ligEPTT amp large market these kinds of as: beer amp EPTTrage, mining EPTT, foodstuff EPTT, textile printing, rubber amp plastic materials, petrochemical business, jack-up transportation, pharmacy amp procedure hides, environmental protection products.

Certification

FAQ

1.Payment Expression: TT, L/C

2.Supply time: about 30 daEPTTfrom EPTT payment.

three.We accept EPT goods as for every your EPTT prerequisite.

4.XiHu (West Lake) Dis.hu (West Lake) Dis.strains for the Assortment:Generally we can decide on one EPTT which is ideal for you with some informations from you,this sort of as ratio/motor pace/mounting dimension/ out torque and so on.

five.If the bare minimum orEPTTamount is in surplus of $10000, there are preferential.

Q1: What data must I tell you to verify the item?

A:Design/Dimensions, EPTT Ratio, Shaft instructions amp OrEPTTquantity.

Q2: What can i do if I will not know which a single EPTT?

A:Dont be concerned, Deliver as significantly information as you can, our crew will support you uncover the rigEPTT 1 you are hunting for.

Q3: What is your product guarantee time period?

A:We offer you a single calendar year warranty because the vessel departure day still left EPTT.

This autumn: Are you trading company or manufacturer ?

A: We are manufacturing unit.

Q5: How EPTT is your shipping time?

A: EPTTly it is five-10 daEPTTif the goods are in stock. or it is 15-20 daEPTTif the goods are not in inventory, it is according to amount.

Q6: Do you offer samples ? is it free of charge or added ?

A: Yes, we could provide the sample for free charge but do not shell out the EPTT of freight.

Q7: What is your terms of payment ?

A: Payment lt=1000USD, a hundred% EPTT. Payment gt=1000USD, thirty% T/T EPTT ,equilibrium ahead of shippment.

If you have one more concern, pls truly feel free of charge to contact us as underneath:

Contact Us

in Kottayam India sales price shop near me near me shop factory supplier RV. MB Series Worm Gear Box Reducer manufacturer best Cost Custom Cheap wholesaler

We provide OEM service. High quality and credit history are the bases that make a company alive. we are self-confident to provide our customers adaptable and diversified companies. RV. MB Series Worm Gear Box EPT

EPT day:

one..Ratio assortment: 7.five-one hundred

two. Enter EPT: .04-15KW

3. Allow torque rang: ten-1500N.m

4. Framework mode: Foot-mounted, enter shaft, with enter flange Added solitary (double) output shaft

Attribute:

1. Compact mechanical structure, ligEPT and useful volume, modest-scale and high productive

2. Excellent temp trade capacity amp trustworthiness

3. EPT mounting, hyperlink freely, effortless verification

4. Vast EPT ratio amp sturdy torque

five. Efficiently EPT, small sounds amp vibration, broadly utilized

Attribute:

1. Great available capability amp trustworthiness

2. Great temperature exchange capability amp large strengthens

three. Carburized and grinded tooth

4. Excellent fabricate ability, can be fabricated with other EPT to realize minimal-speed EPT

in Kikwit Democratic Republic of the Congo sales price shop near me near me shop factory supplier Industrial Worm Gearbox Wp Series Wpdo Worm Gear Speed Reducer manufacturer best Cost Custom Cheap wholesaler

Trying to keep in head that excellent support is the crucial to cooperating with customers, we attempt to fulfill high good quality requirements, offer competitive rates and guarantee prompt shipping and delivery. Our main items are Needle Roller bearings, Cylindrical Roller Bearings, Rod conclude Bearings, Spherical basic bearings, Monitor roller Bearings for Guideway, Roller Bearings, Combine Bearings for forklifts, H2o Pump Bearings, SNR Vehicle Bearings and all sorts of Spherical Bearings. The higher precise CNC products, this sort of as Gradual-feeding wire-minimize equipment, jig grinding device and electric powered discharge machine, assures the leading good quality precision of mould processing, with the high efficient and environmental safety acid rolling line currently being the biggest raw content converting equipment in the subject in china The wildly use of computerized milling device, high-velocity automated feeding punch, higher velocity automatic rolling and assembling device guarantees the substantial quality and effectiveness of parts and chain producing.

gt Product Introduction

Wpw Worm Worm Reductor

one, WP collection worm EPT ‘s the EPT sleek, vibration, EPT and sound are modest, a large reduction ratio, broad versaEPTty, with all varieties of mechanical equipment.

two, WPA series velocity EPT are in a position to get a larger single-phase EPT EPT ratio, compact, most designs have much better EPT self-locking, braking demands for mechanical gear can conserve brakes

3, worm thread engagement with the worm EPT tooth floor friction decline better than the EPT EPT performance and therefore reduced, straightforward to warmth and higher temperatures.

4, interworking excellent worm manufactured according to nationwide stXiHu (West Lake) Dis.Hu (West Lake) Dis.rds, bearings, seals etc with stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd elements. 5,

5, box sort fundamental kind (vertical or horizontal box for two buildings with bottom foot) and the EPT sort (box is rectangular, multi-faceted with fixed screw, not fitted with base foot or the other stop foot and other structural type)

6, WP sequence EPT box input shaft coupling techniques are the fundamental kind (one enter shaft and dual input shaft), two motor with flange.

7, WP series EPT ‘ output, position and direction of the enter shaft and the enter shaft on the following the output aXiHu (West Lake) Dis.s and down the enter shaft and down.

eight, WP collection worm EPT can be two or 3 sets consisting of multi phase EPT EPT to get excellent EPT ratio.

| Sort: | WP EPTs reduction EPT |

| Design: | WPA40-250 |

| Ratio: | 10,15,twenty,twenty five,30,40,50,60 |

| Shade: | Inexperienced,Brown |

| EPT: | Solid iron body |

| Worm Gear- Cooper-ten-three # | |

| Worm-20CrMnTi with carburizing and quenching, area hardness is 56-62HRC | |

| Shaft-chromium metal-forty five# | |

| EPT: | Paper Carton,Plywood box / per established(With foam board inside) |

| Warranty: | 1 yr |

| Input EPT: | .55kw,.75kw,1.1kw,1.5kw,2.2kw,4kw,five.5kw,7.5kw |

| Usages: | In EPT EPT: Meals things,Ceramics,chemical, aswell as EPT, printing, dyeing,woodworking, EPT and plastics #8230.. |

| IEC Flange: | 80B5,90B5,100B5,112B5,132B5…. |

| Lubricant: | Synthetic amp Mineral |

gt Catalogue

gt Our EPT Advantages

1. Affordable value with exceptional top quality

two.Each a single assessments very carefully

3.Clear nameplate

4.Reliable deal

five.High performance, easy runingand lower sound

6.Ideal resources make ideal overall performance

gt Generating Procedure

gt WORKSHOP Equipment:

CERTIFICATION :

gt EPTAGE :

for 1 container, right loading ,for less, all products with pallet,

FAQ

FAQ

1, Q:what is your MOQ for ac EPT motor ?

A: 1pc is alright for each variety electrical EPT box motor

2, Q: What about your guarantee for your induction velocity EPT motor ?

A: 1 yr ,but apart from guy-produced destroyed

three, Q: which payment way you can take ?

A: TT, western union .

4, Q: how about your payment way ?

A: a hundred%payment EPTd considerably less $5000 ,thirty% payment EPTd payment , 70% payment just before sending over $5000.

five, Q: how about your EPT of pace reduction motor ?

A: plywood scenario ,if measurement is small ,we will pack with pallet for much less one container

six, Q: What details ought to be provided, if I get electric helical EPTed motor from you ?

A: rated EPT, ratio or output speed,type ,voltage , mounting way , quantity , if much more is far better.