2. First Inspection: When a new gearbox is installed or in the course of regimen servicing, it is crucial to examine and validate the initial lubricant amount. This establishes a baseline and ensures that the gearbox is stuffed to the appropriate amount in advance of operation.

5. Routine maintenance Agenda: Include lubricant degree checks into your regime servicing schedule. Based on the depth of machines usage, it is normally advised to inspect the lubricant amount on a regular monthly or quarterly foundation. Even so, much more repeated checks may possibly be necessary for weighty-duty apps or when working in extraordinary conditions.

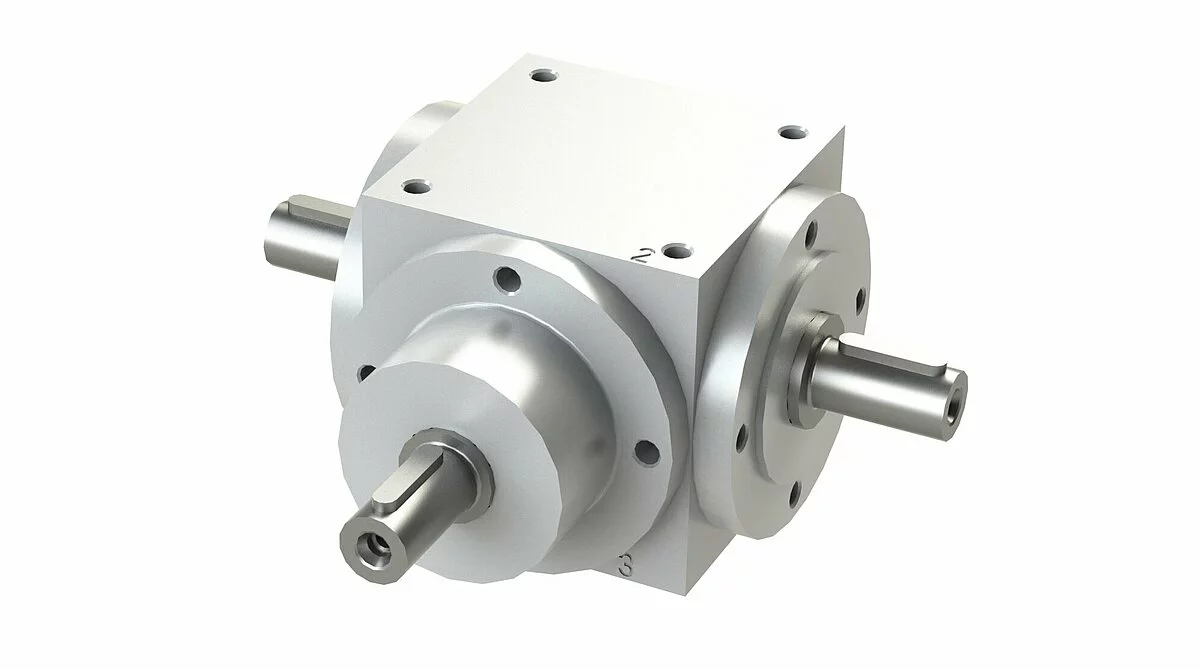

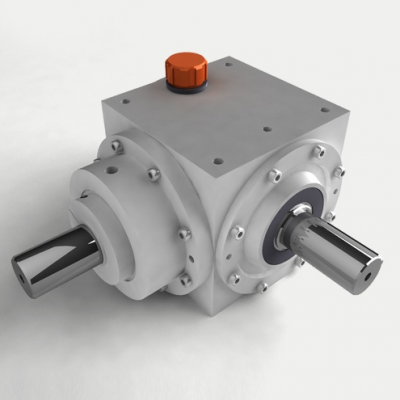

An agricultural gearbox, also acknowledged as a farm gearbox or agricultural transmission, is a mechanical unit used in China agricultural gearbox supplier machines and equipment. It is a crucial component that allows transmit electrical energy from the motor to a wide variety of agricultural implements, enabling the efficient operation of farm products.

The GL classification process is not usually applied for categorizing or China agricultural gearbox supplier classifying old agricultural gearboxes. The GL classification program, also recognised as the Germanischer Lloyd classification system, is principally made use of in the marine marketplace to classify and certify ships and offshore buildings.

Common upkeep, lubrication, and appropriate use of the gearbox are crucial to assure its longevity and excellent efficiency. Makers generally supply tips and China agricultural gearbox manufacturer recommendations for servicing and servicing of their gearboxes to optimize their lifespan and trustworthiness.

eight. Lessened Gearbox Efficiency: If you detect a minimize in the effectiveness or success of your agricultural devices, it could be thanks to lubricant leakage in the gearbox. Lessened general performance, these kinds of as slower operation, lowered power delivery, or problem in shifting gears, may well suggest a leakage-associated situation.

4. Extreme Lubricant Use: If you uncover oneself usually introducing lubricant to the gearbox at shorter intervals than normal, it could be a sign of a leakage difficulty. Continually small lubricant levels inspite of frequent top rated-ups may suggest that the lubricant is escaping from the gearbox.

two. On the internet Marketplaces: On line marketplaces like Amazon, eBay, and Alibaba offer you a broad assortment of agricultural gearboxes. These platforms make it possible for you to assess various brand names, versions, and rates, and often deliver customer critiques to support you make an educated choice. Make guaranteed to verify the believability of the vendor and go through item descriptions and consumer suggestions right before making a invest in.

It’s advisable to assess prices, good quality, and customer reviews before generating a obtain. Reach out to many resources, examine alternatives, and find a trustworthy provider or dealer that provides the gearbox that satisfies your specifications.

1. Local Agricultural Devices Dealers: Local dealerships that focus in agricultural devices, such as tractors and farm machinery, generally carry a variety of agricultural gearboxes. These dealerships usually have proficient personnel who can aid you decide on the right gearbox for your specific demands.

In the agricultural marketplace, gearboxes are generally rated based on their electrical power potential (in horsepower or kilowatts) and intended software, this sort of as for use in tractors, harvesters, or other agricultural machinery. Suppliers generally give technical specs and guidelines for their gearboxes to enable buyers choose the suitable gearbox for their precise agricultural devices.

The most important objective of an agricultural gearbox is to control the velocity and torque of the electrical electric power transmitted from the enter supply, these as a tractor’s electric power select-off (PTO) or motor, to the output shaft that drives the apply or attachment. It permits farmers to adapt the ability and velocity prerequisites to match the precise job at hand, this type of as plowing, tilling, mowing, or harvesting.

When purchasing an agricultural gearbox, it’s crucial to contemplate things like the gearbox’s electricity rating, input and output shaft sizes, gear ratios, and mounting demands to be certain compatibility with your particular tools and application. Furthermore, consider the guarantee, soon after-revenue aid, and availability of spare elements when selecting a provider or producer.

six. Greater Lubricant Use: If you discover oneself usually introducing lubricant to the gearbox at shorter intervals than typical, it may perhaps be a indication of a leakage challenge. A sudden raise in lubricant usage can show that the lubricant is escaping from the gearbox due to a leak.

Agricultural gearboxes are formulated to face up to the demanding challenges and exceptional hundreds encountered in agricultural operations. They are normally produced with durable assets, these as forged iron or metal, and are engineered to supply reputable and considerable-long lasting common general performance.

1. Inside Joint: The interior joint attaches to the transmission or differential and is trusted for transferring torque to the axle shaft.

1. Inside Joint: The interior joint attaches to the transmission or differential and is trusted for transferring torque to the axle shaft.