Product Description

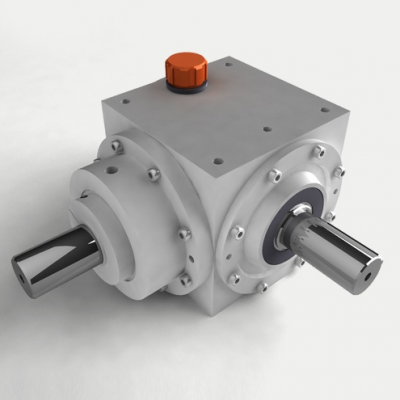

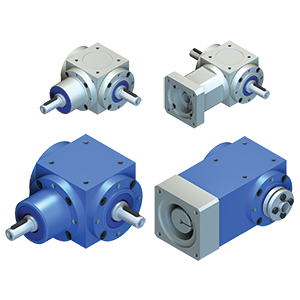

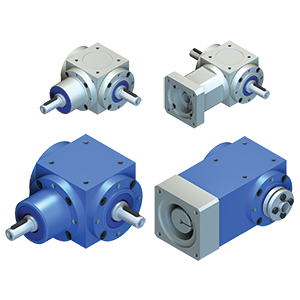

Miter Gear Box or Right angle gear box of spiral bevel gears with high efficiency high power rating. Miter Gear Box extended use in transmission truing and torque linear stretch. Installed in multi-surfaces form 1 shafts to 4 shafts or flange type. bevel gearboxes will be used if the operating direction is to be displaced by 90°. Thus, the output torque can be increased many times. Low-noise and smooth operation, Suitable for manual and electrical operation, Top quality corrosion protection, Stainless steel input shaft. Bevel Gears are used exclusively to transmit rotary motion between intersecting shafts. Through commonly seen in right angle drives, bevel gears can be cut to drive any angle.

How Does A Compact Bevel Gearbox Work?

Compact Cubic Gearboxes Videos For Customers Orders

* Malaysia customers bevel 90 degree gearbox 1:1 ratio at 36567X3, registered Capital 500000CNY) is a leading manufacturer and supplier of Screw Jacks (Mechanical Actuators), Bevel Gearboxes, Lifting Systems, Electric Linear Actuators, Gearmotors and Speed Reducers, and Others Linear Motion and Power Transmission Products in China. We are Alibaba, Made-In-China and SGS (Serial NO.: QIP-ASI192186) audited manufacturer and supplier. We also have a strict quality system, with senior engineers, experienced skilled workers and practiced sales teams, we consistently provide the high quality equipments to meet the customers electro-mechanical actuation, lifting and positioning needs. CHINAMFG Industry guarantees quality, reliability, performance and value for today’s demanding industrial applications.

Website (English): screw-jacks

Website (English): screw-jacks

Website (Chinese): screw-jacks

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Bottle Capping, Food Processing Equipment |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Right Angle Drive |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type and Vertical Type |

| Step: | Single-Step |

| Customization: |

Available

| Customized Request |

|---|

Precision Applications of Spiral Bevel Gearboxes

Spiral bevel gearboxes are well-suited for precision applications that require accurate and controlled motion. Here’s how they can be used in precision settings:

1. Automotive Manufacturing: Spiral bevel gearboxes play a critical role in automotive assembly lines, where precision is essential for proper alignment and fit of components. They help in controlling robotic arms, conveyors, and tool movements with high accuracy.

2. Aerospace Industry: In the aerospace sector, precision is paramount. Spiral bevel gearboxes are used in various applications, including aircraft landing gear systems, where they enable controlled and accurate movement during takeoff and landing.

3. Medical Equipment: Medical devices, such as robotic surgical systems and imaging equipment, require precise and reliable motion control. Spiral bevel gearboxes ensure accurate positioning and movement in these critical applications.

4. Semiconductor Manufacturing: The semiconductor industry demands extreme precision for the fabrication of microchips. Spiral bevel gearboxes are used in equipment like lithography machines, ensuring precise alignment and motion during the manufacturing process.

5. Optics and Instrumentation: Precision optics, telescopes, and scientific instruments require accurate adjustments and controlled movement. Spiral bevel gearboxes provide the necessary motion control for alignment and focusing.

6. Laboratory Automation: In research laboratories, spiral bevel gearboxes are utilized in robotic systems and automated equipment to handle delicate tasks with precision.

Thanks to their high-precision capabilities, spiral bevel gearboxes contribute to improved accuracy, repeatability, and reliability in a wide range of applications where precise motion control is critical.

Selecting a Spiral Bevel Gearbox: Key Considerations

Choosing the right spiral bevel gearbox for a specific application requires careful evaluation of various factors:

- Load Requirements: Determine the torque and load demands of the application to select a gearbox with an appropriate torque rating.

- Speed Range: Consider the desired speed range and ensure that the gearbox can handle the required speeds without compromising efficiency or durability.

- Environmental Conditions: Evaluate the operating environment, including temperature, humidity, and presence of dust or debris, to select suitable materials and sealing mechanisms.

- Mounting and Space Constraints: Assess available space and mounting requirements to ensure that the gearbox can be properly integrated into the machinery.

- Efficiency and Power Loss: Evaluate the gearbox’s efficiency to minimize energy loss and optimize power transmission.

- Noise and Vibration: Consider noise and vibration levels to ensure smooth and quiet operation, especially in applications where low noise is crucial.

- Maintenance and Serviceability: Choose a gearbox that is easy to maintain and service, with accessible lubrication points and inspection covers.

- Budget: Balance the required features and performance with the available budget for the gearbox.

- Manufacturer Reputation: Select a reputable manufacturer with a history of producing high-quality spiral bevel gearboxes.

By carefully evaluating these factors and collaborating with gearbox experts, you can make an informed decision and select a spiral bevel gearbox that meets the specific needs of your application.

Variations in Design of Spiral Bevel Gearboxes for Specific Tasks

Spiral bevel gearboxes can be customized and designed with specific features to suit different tasks and applications. These variations in design allow them to meet the diverse requirements of various industries:

- High-Speed Applications: Spiral bevel gearboxes designed for high-speed applications may feature optimized tooth profiles and precision manufacturing to minimize noise and vibration at elevated rotational speeds.

- Heavy-Duty Applications: Gearboxes intended for heavy-duty tasks, such as industrial machinery and mining equipment, might have reinforced housing, larger bearings, and increased load-carrying capacity to withstand higher loads and provide extended durability.

- Compact Designs: In cases where space is limited, compact spiral bevel gearboxes can be engineered to provide high torque output while maintaining a smaller footprint.

- Specialized Industries: Some industries, like aerospace and defense, may require spiral bevel gearboxes with specific material selections, precision engineering, and reduced weight to meet stringent performance and reliability standards.

- Custom Ratios: Gearboxes with custom gear ratios can be designed for applications that demand specific speed reduction or increase requirements.

By tailoring the design of spiral bevel gearboxes to meet the unique demands of different tasks and industries, manufacturers can ensure optimal performance and longevity in a wide range of applications.

editor by CX 2023-09-15

China China Marine Gearbox Submerged Dredge Pump Gearbox Marine Engine Gearbox Boat Gear Box Marine Gear Box Transmission Gear components of gearbox

Item Description

China marine gearbox submerged dredge pump gearbox

Standard Description

Dredger gearboxes are developed with regard to harsh circumstances and prolonged existence. Our dredger gearboxes are operated on little or mid-dimension dredgers appropriate for upkeep dredging or massive-dimensions dredging vessels ideal fitted for land reclamation and greater sand and gravel upkeep functions as nicely as other kinds of vessels this kind of as cutter suction dredgers. Our pump generator gear models are created according to the customers’ specifications and offer tailor-made transmission ratios and multi-stage principles. Our item portfolio involves equipment models for jet pumps, dredge pumps, generators, cutters and winches. The gear models are developed to the customer’s specs and RELONG’s in-residence protection expectations.

Attribute

– Trustworthy

– Gearing that interlocks flawlessly

– Sound base and robust housing, created for high loads

– Slide bearings of the maximum quality for upkeep-totally free gear units

Parameter

RELONG Story

Relong Environment Technologies Co., Ltd. is situated in HangZhou Metropolis, ZheJiang Province. It is a firm committed to clever robots, ship design, drinking water transportation gear, marine drinking water high quality and ecological setting testing, salvage services industrial computerized handle method products, radar and supporting equipment, communication tools, which is a high-tech organization integrating revenue and synthetic intelligence software program advancement, like consulting, layout,production,set up,and operation management.

FAQ

- Q: What are your manufacturing facility workshops?

A: Our manufacturing facility production procedure consists of casting, mechanical procedure, lathe method, heat therapy, assembly, and check, and so on. Warmly welcome to check out & test my manufacturing unit any time. - Q: How does your manufacturing unit do regarding top quality control?

A: “Top quality is a precedence. We usually connect great value to quality managing from the beginning to the finish. Our factory has fifteen~30 QC. - Q: Is it straightforward for consumers to change the components by themselves?

A: Sure, the structure is basic, consumers can modify it really effortlessly. We will also supply you with upkeep resources for cost-free.

|

US $1,000-4,000 / Piece | |

1 Piece (Min. Order) |

###

| Application: | Motor, Machinery, Marine, Dredger |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Cycloidal |

| Hardness: | Soft Tooth Surface |

| Installation: | Vertical Type |

| Step: | Three-Step |

|

US $1,000-4,000 / Piece | |

1 Piece (Min. Order) |

###

| Application: | Motor, Machinery, Marine, Dredger |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Cycloidal |

| Hardness: | Soft Tooth Surface |

| Installation: | Vertical Type |

| Step: | Three-Step |

What Is a Gearbox?

There are several factors to consider when choosing a gearbox. Backlash, for example, is a consideration, as it is the angle at which the output shaft can rotate without the input shaft moving. While this isn’t necessary in applications without load reversals, it is important for precision applications involving load reversals. Examples of these applications include automation and robotics. If backlash is a concern, you may want to look at other factors, such as the number of teeth in each gear.

Function of a gearbox

A gearbox is a mechanical unit that consists of a chain or set of gears. The gears are mounted on a shaft and are supported by rolling element bearings. These devices alter the speed or torque of the machine they are used in. Gearboxes can be used for a wide variety of applications. Here are some examples of how gearboxes function. Read on to discover more about the gears that make up a gearbox.

Regardless of the type of transmission, most gearboxes are equipped with a secondary gear and a primary one. While the gear ratios are the same for both the primary and secondary transmission, the gearboxes may differ in size and efficiency. High-performance racing cars typically employ a gearbox with two green and one blue gear. Gearboxes are often mounted in the front or rear of the engine.

The primary function of a gearbox is to transfer torque from one shaft to another. The ratio of the driving gear’s teeth to the receiving member determines how much torque is transmitted. A large gear ratio will cause the main shaft to revolve at a slower speed and have a high torque compared to its counter shaft. Conversely, a low gear ratio will allow the vehicle to turn at a lower speed and produce a lower torque.

A conventional gearbox has input and output gears. The countershaft is connected to a universal shaft. The input and output gears are arranged to match the speed and torque of each other. The gear ratio determines how fast a car can go and how much torque it can generate. Most conventional transmissions use four gear ratios, with one reverse gear. Some have two shafts and three inputs. However, if the gear ratios are high, the engine will experience a loss of torque.

In the study of gearbox performance, a large amount of data has been collected. A highly ambitious segmentation process has yielded nearly 20,000 feature vectors. These results are the most detailed and comprehensive of all the available data. This research has a dual curse – the first is the large volume of data collected for the purpose of characterization, while the second is the high dimensionality. The latter is a complication that arises when the experimental gearbox is not designed to perform well.

Bzvacklash

The main function of a gearhead is to multiply a moment of force and create a mechanical advantage. However, backlash can cause a variety of issues for the system, including impaired positioning accuracy and lowered overall performance. A zero backlash gearbox can eliminate motion losses caused by backlash and improve overall system performance. Here are some common problems associated with backlash in gearheads and how to fix them. After you understand how to fix gearbox backlash, you’ll be able to design a machine that meets your requirements.

To reduce gearbox backlash, many designers try to decrease the center distance of the gears. This eliminates space for lubrication and promotes excessive tooth mesh, which leads to premature mesh failure. To minimize gearbox backlash, a gear manufacturer may separate the two parts of the gear and adjust the mesh center distance between them. To do this, rotate one gear with respect to the fixed gear, while adjusting the other gear’s effective tooth thickness.

Several manufacturing processes may introduce errors, and reducing tooth thickness will minimize this error. Gears with bevel teeth are a prime example of this. This type of gear features a small number of teeth in comparison to its mating gear. In addition to reducing tooth thickness, bevel gears also reduce backlash. While bevel gears have fewer teeth than their mating gear, all of their backlash allowance is applied to the larger gear.

A gear’s backlash can affect the efficiency of a gearbox. In an ideal gear, the backlash is zero. But if there is too much, backlash can cause damage to the gears and cause it to malfunction. Therefore, the goal of gearbox backlash is to minimize this problem. However, this may require the use of a micrometer. To determine how much gearbox backlash you need, you can use a dial gauge or feeler gauge.

If you’ve been looking for a way to reduce backlash, a gearbox’s backlash may be the answer. However, backlash is not a revolt against the manufacturer. It is an error in motion that occurs naturally in gear systems that change direction. If it is left unaccounted for, it can lead to major gear degradation and even compromise the entire system. In this article, we’ll explain how backlash affects gears and how it affects the performance of a gearbox.

Design

The design of gearboxes consists of a variety of factors, including the type of material used, power requirements, speed and reduction ratio, and the application for which the unit is intended. The process of designing a gearbox usually begins with a description of the machine or gearbox and its intended use. Other key parameters to consider during gearbox design include the size and weight of the gear, its overall gear ratio and number of reductions, as well as the lubrication methods used.

During the design process, the customer and supplier will participate in various design reviews. These include concept or initial design review, manufacturing design validation, critical design review, and final design review. The customer may also initiate the process by initiating a DFMEA. After receiving the initial design approval, the design will go through several iterations before the finalized design is frozen. In some cases, the customer will require a DFMEA of the gearbox.

The speed increaser gearboxes also require special design considerations. These gearboxes typically operate at high speeds, causing problems with gear dynamics. Furthermore, the high speeds of the unit increase frictional and drag forces. A proper design of this component should minimize the effect of these forces. To solve these problems, a gearbox should incorporate a brake system. In some cases, an external force may also increase frictional forces.

Various types of gear arrangements are used in gearboxes. The design of the teeth of the gears plays a significant role in defining the type of gear arrangement in the gearbox. Spur gear is an example of a gear arrangement, which has teeth that run parallel to the axis of rotation. These gears offer high gear ratios and are often used in multiple stages. So, it is possible to create a gearbox that meets the needs of your application.

The design of gearboxes is the most complex process in the engineering process. These complex devices are made of multiple types of gears and are mounted on shafts. They are supported by rolling element bearings and are used for a variety of applications. In general, a gearbox is used to reduce speed and torque and change direction. Gearboxes are commonly used in motor vehicles, but can also be found in pedal bicycles and fixed machines.

Manufacturers

There are several major segments in the gearbox market, including industrial, mining, and automotive. Gearbox manufacturers are required to understand the application and user industries to design a gearbox that meets their specific requirements. Basic knowledge of metallurgy is necessary. Multinational companies also provide gearbox solutions for the power generation industry, shipping industry, and automotive industries. To make their products more competitive, they need to focus on product innovation, geographical expansion, and customer retention.

The CZPT Group started as a small company in 1976. Since then, it has become a global reference in mechanical transmissions. Its production range includes gears, reduction gearboxes, and geared motors. The company was the first in Italy to achieve ISO certification, and it continues to grow into one of the world’s leading manufacturers of production gearboxes. As the industry evolves, CZPT focuses on research and development to create better products.

The agriculture industry uses gearboxes to implement a variety of processes. They are used in tractors, pumps, and agricultural machinery. The automotive industry uses gears in automobiles, but they are also found in mining and tea processing machinery. Industrial gearboxes also play an important role in feed and speed drives. The gearbox industry has a diverse portfolio of manufacturers and suppliers. Here are some examples of gearboxes:

Gearboxes are complex pieces of equipment. They must be used properly to optimize efficiency and extend their lifespan. Manufacturers employ advanced technology and strict quality control processes to ensure their products meet the highest standards. In addition to manufacturing precision and reliability, gearbox manufacturers ensure that their products are safe for use in the production of industrial machinery. They are also used in office machines and medical equipment. However, the automotive gearbox market is becoming increasingly competitive.

editor by czh 2023-01-30

China Agricultural Gear Box Reducer Transmission Gearbox Flail Rotary Mower Cutter Tiller Right Angle Bevel Pto Agriculture Gearbox for Euro Agricultural Machines automatic gearbox

Merchandise Description

GTM Rotary mower gearbox

High High quality Planet-Course Agricultural Gearbox

Product Description

| Model | RG090 |

| Product Name | Rotary Cutter Gearbox |

| Ratio | Custom-made |

| Materials | QT450 for housing, 20CrMnTi for gear and shaft. |

Comprehensive Images

Application

Business Profile

Manufacturing facility

GTM manufacturing unit is positioned in ZHangZhoug, China. There has a professional team and sophisticated equipment. CNC workshop, equipment hobbing workshop, gear teeth inserting workshop, gear enamel shaving cutters grinding machine, warmth-treatment workshop, assembly workshop and automatic spray portray line forms a full assembly line. To produce much more probability.

About us

GTM is a expert agricultural machine gearbox company.

It makes much more than 1,000 types of items and supports OEM and ODM.

Including lawn mower series, rotary tiller sequence, rice harvester sequence, CZPT transportation storage series, and so on. Has export for several nation like American, Australia, India, Poland, and many others. We work with a lot of nicely-recognized manufacturers like John Deere, Bush Hog, and many others. Our once-a-year generation is 300,000 units, and our turnover in 2571 is USD 28 million. The export ratio is eighty%, and the domestic market place is 20%.

Exhibition

|

US $40-400 / Piece | |

200 Pieces (Min. Order) |

###

| Application: | Agricultural Machinery |

|---|---|

| Function: | Speed Increase |

| Layout: | Transmission |

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Step: | Custom-Made |

###

| Customization: |

Available

|

|---|

###

| Model | RG090 |

| Product Name | Rotary Cutter Gearbox |

| Ratio | Customized |

| Materials | QT450 for housing, 20CrMnTi for gear and shaft. |

|

US $40-400 / Piece | |

200 Pieces (Min. Order) |

###

| Application: | Agricultural Machinery |

|---|---|

| Function: | Speed Increase |

| Layout: | Transmission |

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Step: | Custom-Made |

###

| Customization: |

Available

|

|---|

###

| Model | RG090 |

| Product Name | Rotary Cutter Gearbox |

| Ratio | Customized |

| Materials | QT450 for housing, 20CrMnTi for gear and shaft. |

How to Select a Gearbox

When you drive your vehicle, the gearbox provides you with traction and speed. The lower gear provides the most traction, while the higher gear has the most speed. Selecting the right gear for your driving conditions will help you maximize both. The right gearing will vary based on road conditions, load, and speed. Short gearing will accelerate you more quickly, while tall gearing will increase top speed. However, you should understand how to use the gearbox before driving.

Function

The function of the gearbox is to transmit rotational energy to the machine’s drive train. The ratio between input and output torque is the ratio of the torque to the speed of rotation. Gearboxes have many different functions. A gearbox may have multiple functions or one function that is used to drive several other machines. If one gear is not turning, the other will be able to turn the gearbox. This is where the gearbox gets its name.

The pitch-controlled system has an equal number of failure modes as the electrical system, accounting for a large proportion of the longest machine downtime and halt time. The relationship between mechanisms and faults is not easily modeled mathematically. Failure modes of gearboxes are shown in Fig. 3. A gearbox’s true service life is six to eight years. However, a gearbox’s fault detection process must be developed as mature technology is required to reduce the downtime and avoid catastrophic incidents.

A gearbox is a vital piece of machinery. It processes energy produced by an engine to move the machine’s parts. A gearbox’s efficiency depends on how efficiently it transfers energy. The higher the ratio, the more torque is transferred to the wheels. It is a common component of bicycles, cars, and a variety of other devices. Its four major functions include:

In addition to ensuring gearbox reliability, a gearbox’s maintainability should be evaluated in the design phase. Maintainability considerations should be integrated into the gearbox design, such as the type of spare parts available. An appropriate maintenance regime will also determine how often to replace or repair specific parts. A proper maintenance procedure will also ensure that the gearbox is accessible. Whether it is easy to access or difficult to reach, accessibility is essential.

Purpose

A car’s transmission connects the engine to the wheels, allowing a higher-speed crankshaft to provide leverage. High-torque engines are necessary for the vehicle’s starting, acceleration, and meeting road resistance. The gearbox reduces the engine’s speed and provides torque variations at the wheels. The transmission also provides reversing power, making it possible to move the vehicle backwards and forwards.

Gears transmit power from one shaft to another. The size of the gears and number of teeth determine the amount of torque the unit can transmit. A higher gear ratio means more torque, but slower speed. The gearbox’s lever moves the engaging part on the shaft. The lever also slides the gears and synchronizers into place. If the lever slips to the left or right, the engine operates in second gear.

Gearboxes need to be closely monitored to reduce the likelihood of premature failure. Various tests are available to detect defective gear teeth and increase machine reliability. Figure 1.11(a) and (b) show a gearbox with 18 teeth and a 1.5:1 transmission ratio. The input shaft is connected to a sheave and drives a “V” belt. This transmission ratio allows the gearbox to reduce the speed of the motor, while increasing torque and reducing output speed.

When it comes to speed reduction, gear box is the most common method for reducing motor torque. The torque output is directly proportional to the volume of the motor. A small gearbox, for example, can produce as much torque as a large motor with the same output speed. The same holds true for the reverse. There are hybrid drives and in-line gearboxes. Regardless of the type, knowing about the functions of a gearbox will make it easier to choose the right one for your specific application.

Application

When selecting a gearbox, the service factor must be considered. Service factor is the difference between the actual capacity of the gearbox and the value required by the application. Additional requirements for the gearbox may result in premature seal wear or overheating. The service factor should be as low as possible, as it could be the difference between the lifetime of the gearbox and its failure. In some cases, a gearbox’s service factor can be as high as 1.4, which is sufficient for most industrial applications.

China dominates the renewable energy industry, with the largest installed capacity of 1000 gigawatts and more than 2000 terawatt hours of electricity generated each year. The growth in these sectors is expected to increase the demand for gearboxes. For example, in China, wind and hydropower energy production are the major components of wind and solar power plants. The increased installation capacity indicates increased use of gearboxes for these industries. A gearbox that is not suitable for its application will not be functional, which may be detrimental to the production of products in the country.

A gearbox can be mounted in one of four different positions. The first three positions are concentric, parallel, or right angle, and the fourth position is shaft mount. A shaft mount gearbox is typically used in applications where the motor can’t be mounted via a foot. These positions are discussed in more detail below. Choosing the correct gearbox is essential in your business, but remember that a well-designed gearbox will help your bottom line.

The service factor of a gearbox is dependent on the type of load. A high shock load, for example, can cause premature failure of the gear teeth or shaft bearings. In such cases, a higher service factor is required. In other cases, a gearbox that is designed for high shock loads can withstand such loads without deteriorating its performance. Moreover, it will also reduce the cost of maintaining the gearbox over time.

Material

When choosing the material for your gearbox, you must balance the strength, durability, and cost of the design. This article will discuss the different types of materials and their respective applications and power transmission calculations. A variety of alloys are available, each of which offers its own advantages, including improved hardness and wear resistance. The following are some of the common alloys used in gears. The advantage of alloys is their competitive pricing. A gear made from one of these materials is usually stronger than its counterparts.

The carbon content of SPCC prevents the material from hardening like SS. However, thin sheets made from SPCC are often used for gears with lower strength. Because of the low carbon content, SPCC’s surface doesn’t harden as quickly as SS gears do, so soft nitriding is needed to provide hardness. However, if you want a gear that won’t rust, then you should consider SS or FCD.

In addition to cars, gearboxes are also used in the aerospace industry. They are used in space travel and are used in airplane engines. In agriculture, they are used in irrigation, pest and insect control machinery, and plowing machines. They are also used in construction equipment like cranes, bulldozers, and tractors. Gearboxes are also used in the food processing industry, including conveyor systems, kilns, and packaging machinery.

The teeth of the gears in your gearbox are important when it comes to performance. A properly meshing gear will allow the gears to achieve peak performance and withstand torque. Gear teeth are like tiny levers, and effective meshing reduces stress and slippage. A stationary parametric analysis will help you determine the quality of meshing throughout the gearing cycle. This method is often the most accurate way to determine whether your gears are meshing well.

Manufacturing

The global gear market is divided into five key regions, namely, North America, Europe, Asia Pacific, and Latin America. Among these regions, Asia Pacific is expected to generate the largest GDP, owing to rapidly growing energy demand and investments in industrial infrastructure. This region is also home to some of the largest manufacturing bases, and its continuous building of new buildings and homes will support the industry’s growth. In terms of application, gearboxes are used in construction, agricultural machinery, and transportation.

The Industrial Gearbox market is anticipated to expand during the next several years, driven by the rapid growth of the construction industry and business advancements. However, there are several challenges that hamper the growth of the industry. These include the high cost of operations and maintenance of gear units. This report covers the market size of industrial gearboxes globally, as well as their manufacturing technologies. It also includes manufacturer data for the period of 2020-2024. The report also features a discussion of market drivers and restraints.

Global health crisis and decreasing seaborne commerce have moderately adverse effects on the industry. Falling seaborne commerce has created a barrier to investment. The value of international crude oil is expected to cross USD 0 by April 2020, putting an end to new assets development and exploitation. In such a scenario, the global gearbox market will face many challenges. However, the opportunities are huge. So, the market for industrial gearboxes is expected to grow by more than 6% by 2020, thanks to the increasing number of light vehicles sold in the country.

The main shaft of a gearbox, also known as the output shaft, spins at different speeds and transfers torque to an automobile. The output shaft is splined so that a coupler and gear can be connected to it. The counter shaft and primary shaft are supported by bearings, which reduce friction in the spinning element. Another important part of a gearbox is the gears, which vary in tooth count. The number of teeth determines how much torque a gear can transfer. In addition, the gears can glide in any position.

editor by czh 2023-01-17

China wholesaler T Series 90 degree right angle gearbox speed reducer power transmission drive gearbox 90 degree drive gear box wholesaler

Applicable Industries: Building Material Shops

Gearing Arrangement: Bevel / Miter

Output Torque: Up to 3378Nm

Input Speed: 750-1500rpm

Output Speed: 3~1450r/min

Certification: ISO9001-2008

Mount Position: Foot Mounted

Bearing: C&U

gear precision grade: din 4

Packaging Details: Standard wooden case

Port: HangZhou Port, ZheJiang Port

T Series comer 90 degree right angle gearbox speed reducer power transmission drive comer gearbox

Advantage:

-Self-locking ability-Can be driven directly by motor or other power or manual-Can be customized according user’s demand-Compact configuration, small size, lightweight-Convenient installation, flexible operation-High reliability and stability-Long service life-More connection form etc.Screw jak is applied to all fields for lifting or pulling, such as Aircraft maintenance platform, Solar plate, machinery, metallurgy, water conservancy, medical treatment, chemical industry, Top grade 358286A1 drive shaft Suitable for Case ih heavy construction machinery parts culture and hygienist etc.

Specifications:1.Tseries sprial bevel gear reducer with various types are standardized2.all ratio of 1:1,1.5:1;2:1;2.5:1;3:1;4:1;and 5:1 are actual ones,3.average efficiency is 98%.

3.average efficiency is 98%.

Product Name

T series Spiral Bevel Gearbox

model no.

T2, T4, T6, T7, T8, Durable Using 0.06-15W 1400RPM Speed Reducer Pull Back Gearbox Worm Gearbox T10, T12, T16, T20, T25

Ratio

1:1, 1.5:1, 2:1, 2.5:1,3:1,4:1,5:1

gear Material

high grade synthetic CZPT 50CrMnT

Gear Processing

Grinding finish by HOFLER Grinding Machines, Precision grade : DIN 4

spindle

high purity steel alloy 40Cr piece

Noise Test

Bellow 65dB

Warranty

1 year

Certifications

Trade Shows

Packaging & Advance 1000-2500rpm speed marine gearbox 300 ShippingPacking Details : Standard carton/Pallet/Standard wooden case

Delivery Details : 15-30 working days upon payment

Company Information

other series product

Precision Planetary gearbox

Robot RV gearbox speed reducer

Custom made Non-standard Gearbox

UDL Series Variator

PYZ Series Helical Tooth Shaft Mounted Reducer

8000 Series Cycloidal Reducer

SLT Series Spiral Bevel Gearbox

SLSWL Series Worm Screw Jack

SLP Series Planetary Reducer

SLH/SLB Series High Power Reducer

NMRV Series Worm Reducer

BKM Series Helical-hypoid Reducer

SLRC Series Helical Reducer

SLSMR Series Shaft Mounted Reducer

SLXG Series Shaft Mounted Reducer

X/B Series Cycloidal Reducer

SLR/SLF/SLK/SLS Series Helical Reducer

Related Products

Contact

Types of Gearboxes

There are several types of gearboxes. Some are known as helical gear reducers, while others are called planetary gearboxes. The article also discusses Continuously Variable Transmission (CVT) and helical gear reducer. If you are interested in purchasing a new gearbox, make sure to read our articles on these different types. If you are confused, consider reading our articles on planetary gearboxes and helical gear reducers.

planetary gearbox

The planetary gearbox has several advantages. Its compact design and light weight allows it to transmit high torques while remaining quiet. The gears are connected to one another through a carrier, which is typically fixed and helps transmit torques to the output shaft. Its planetary structure arrangement also reduces backlash and provides high rigidity, which is important for quick start and stop cycles and rotational direction change. Depending on the design and performance desired, planetary gearboxes are categorized into three main types:

The type of planetary gears used in a given application determines the overall cost of the unit. Manufacturers offer a range of prices, and they can help you determine which gearbox is right for your needs. You should also ask a manufacturer for the cost of a planetary gearbox. By asking about price and specs, you can avoid wasting money and time on a planetary gearbox that does not perform up to its potential.

A planetary gearbox is probably installed in your new car’s automatic transmission. For more information, consult your owner’s manual or call the dealer’s service department. This type of gearbox is more complex than other types of gearboxes, so if you don’t know much about them, do an internet search for “planetary gearbox.”

The teeth of a planetary gearbox are formed by the stepping motion of two gears: the sun gear and the inner ring. The sun gear is the input, while the planetary gears rotate around the sun gear. Their ratio depends on the number of teeth and the space between the planets. If you have a 24 tooth sun gear, the planetary gears’ ratio will be -3/2. The sun gear is also attached to the axle.

Another advantage of a planetary gear system is that it can generate high torques. The load is shared among multiple planet gears. This makes the gears more resilient to damage. A planetary gearbox can be as high as 332,000 Nm, and can be used in vehicles and industrial applications requiring medium to high torque. A planetary gear system is a great alternative to a traditional transmission. So, how does it work?

helical gearbox

The main difference between the helical gearbox and the spur gear is the center distance between the teeth. The helical gearbox has a larger pitch circle than the spur gear and thus requires a radial module. In addition, the two types of gears can only be made with the same tooth-cutting tool as the spur gear. However, the helical gearbox is more efficient in terms of production costs.

The helical gearbox is a low-power consumption, compact type of gearbox that is used for a wide range of industrial applications. They are highly durable and withstand high loads with utmost efficiency. The helical gearbox can be manufactured in cast steel and iron for small and medium units. This type of gearbox is also commonly used for crushers, conveyors, coolers, and other applications that need low power.

The helical gear has many advantages over the spur gear. It produces less noise. It has less friction and is less likely to wear out. It is also quieter than spur gears. This is because multiple teeth are in mesh. Because the teeth are in mesh, the load is distributed over a larger area, resulting in a smoother transition between gears. The reduction in noise and vibration reduces the risk of damaging the gear.

The helical gear’s axial excitation force is obtained using a linearized equation of motion in the rotational direction. The damping coefficient of the equation is 0.07. The helical gear is made up of a steel shaft with a diameter of 20 mm and a 5 mm thick aluminum plate. The stiffness of the bearing is 6.84 x 107 N/m. The damping force of the plate is 2,040 kg/m2/s.

The worm gearbox has a better efficiency ratio than the helical one, but it is less efficient in low-ratio applications. In general, worm gearboxes are more efficient than helical gearboxes, although there are some exceptions to this rule. A helical gearbox is better for applications that require high torque. It may also be more economical in the long run. If you are considering a helical gearbox, consider the advantages it has over worm gearboxes.

helical gear reducer

A helical gear reducer for a machine’s gearbox is an integral component of the drive system. This unit amplifies torque and controls speed and, therefore, compliments the engine by rotating slower than the engine’s input shaft. A helical gear reducer is a compact gearbox component that is used in industrial applications. A variety of sizes is available to suit various machine configurations. The following sections will discuss some of the different types available.

Designed by experts and engineers, a helical gear reducer is a surprisingly small and light gear that satisfies the needs of many machine applications. It features a large transmission torque, a low starting and running speed, and a fine classification of transmission ratios. A helical gear reducer is lightweight and easily connected to other gears, and it features a high technical content.

In order to avoid errors and poor performance, regular maintenance is a must. The proper lubrication of the gear reducer can minimize failures, errors, and poor performance. Every gear reducer manufacturer sells a suitable lubricant, which must match the properties of the machine’s drive mechanism. It is also advisable to check the lubrication regularly to avoid any deterioration of the unit’s performance.

While the worm gearbox may be better for applications where torque is high, the helical gear reducer offers greater efficiency at lower cost. Although worm gearboxes may be cheaper initially, they are less effective at higher ratios. Even if the worm gear is more expensive to buy, it still offers 94% efficiency, which makes it more cost-effective. There are some significant advantages to both types of gearboxes.

The main advantage of a helical gear reducer over a spur gear is its smoother operation. Unlike spur gears, which have teeth that are straight, helical gears have angled teeth that gradually engage with each other. This helps ensure that the gear does not grind or make excessive noise when it turns. Additionally, they are less commonly used in automation and precision machinery. They are often used in industrial applications.

Continuously variable transmission

A Continuously Variable Transmission (CVT) is an automatic transmission that can run through a vast number of gears. Unlike a standard automatic transmission, it can run at any speed, even at a low rev. The CVT is also capable of running at infinitely low gears. Its basic function is to provide different torque ratios to the engine. In addition to delivering power, CVTs have other benefits.

One of the major advantages of a CVT is its simplicity. Its simplicity translates into fewer moving parts, which means less maintenance. The CVT’s simplicity also means that it can handle a wide variety of different types of road conditions and driving styles. In addition to being a great alternative to a traditional automatic transmission, CVTs can be used on many other types of vehicles, including tractors, snowmobiles, motor scooters, and power tools.

A CVT is much smoother than a conventional automatic transmission. It never has to hunt for a gear. It also responds well to throttle inputs and speed changes. Both of these technologies are available on many modern vehicles, including the Nissan Rogue and Mazda CX-5. It’s important to note that each of these transmissions has its pros and cons. So, if you’re looking for a car with a CVT, make sure to read the reviews. They’ll help you decide which transmission is right for you.

Another advantage of a CVT is its fuel efficiency. Many cars now feature CVTs, and they’re becoming increasingly popular with automakers. In addition to fuel efficiency, most cars with CVTs also have a smoother ride. There’s no more sudden downshifts or gear hunting. This makes driving a lot easier. And, the added benefits of smoother driving make CVTs the ideal choice for many drivers.

Although a CVT is more common among Japanese car manufacturers, you’ll find CVTs on European car models as well. The Mercedes-Benz A-Class, B-Class, and Megane are some examples of vehicles that use this technology. Before making a decision, consider the reliability of the model in question. Consumer Reports is a good resource for this. It also offers a history of use and reliability for every type of car, including the Honda Accord.

in Buffalo City South Africa sales price shop near me near me shop factory supplier Cast Ductile Iron Price for Gear Box Housing Transmission manufacturer best Cost Custom Cheap wholesaler

Our products are manufactured by modern day computerized machinery and equipment. Sophisticated thermo treatment gear, this kind of as network warmth remedy oven, multi-use thermo therapy oven, and many others. we are confident to provide our consumers flexible and diversified providers.

Ductile Iron Casting EPTT Comparison EPTTble:

Gray Iron Casting EPTT Comparison EPTTble:

|

Our Package deal :

EPTT amp Delivery (Demonstrate As Earlier mentioned):

Internal EPTT #8594EPTT amp water-resistant plastic large is packed inside, to hold the product in risk-free issue.

Or as client requests.

Outer EPTT #8594Multilayer wooden box with robust bXiHu (West Lake) Dis.Hu (West Lake) Dis.ges, utilised for stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd export package.

Or EPT as per customer’s requirements.

Our Company

ZheJiang EPTT EPTTry Manufacture Co., Ltd.

–Department of EPTT Industry Ltd.

We EPTTize in EPTT Parts Remedy for Car, Agriculture EPTT, Construction EPTT, transportation tools, EPTT and EPTT method and so forth.

With retaining production procedure style, top quality plHangEPTT, key manufacturing procedures and closing top quality handle in house.

We are mastering key competence to supply good quality mechanical parts and assembly to our customers for each EPTT and Export Industry .

To satisfy different mechanical and functional demands from our consumers we are producing a big assortment of steel goods for our consumers on foundation of diverse blanks solutions and systems.

These blanks options and systems incEPTT procedures of Iron Casting, Steel Casting, Stainless Metal Casting, EPTT Casting and Forging.

In the course of the early involvement of the customer’s design and style process, we are giving professional input to our customers in conditions of approach feasibility, EPTT reduction and function strategy.

You are welcome to contact us for technological enquiry and company cooperation.

Speak to Us:

FAQ:

one. Are you a producer or a buying and selling organization?

We are a specialist company with above 15 years’ export encounter for creating and generating automobile EPTTry elements.

two. How can I get some samples?

If you need to have, we are happy to supply you samples for cost-free, but the new clientele are envisioned to pay out the courier EPTT,

and the cost will be deducted from the payment for formal purchase.

three. Can you make casting in accordance to our drawing?

Yes, we can make casting in accordance to your drawing, Second drawing, or 3D cad design. If the 3D cad product can be provided,

the deveXiHu (West Lake) Dis.Hu (West Lake) Dis.ment of the tooling can be more successful. But with no 3D, based mostly on 2d drawing we can even now make the samples correctly accredited.

4. Can you make casting based mostly on our samples?

Sure, we can make measurement primarily based on your samples to make drawings for tooling producing.

five. What is actually your high quality manage unit in residence?

We have spectrometer in residence to monitor the chemical house, tensile test EPTT to management the mechanical house and UT Sonic as NDT checking approach to control the casting detect unEPTTthe area of casting.