Product Description

| Product Features | Description |

| Product Models | T2, T4, T6, T7, T8, T10, T12, T16, T20, T25, Z2, Z4, Z6, Z7, Z8, Z10, Z12, Z16, Z20, Z25, JRTM2, JRTM4, JRTM6, JRTM7, JRTM8, JRTM10, JRTM12, JRTM16, JRTM20, JRTM25 |

| Maintenance | Clean internally and replace lubricant after initial use of 2 weeks or 100-200 hours. For long-term use, replace lubricant every half to 1 year or every 1000-2000 hours |

| Lubricant | China Petroleum’s all-effect gear oil of 90-120 degrees. Under low speed and light load conditions, it is recommended to use all-effect gear oil of 90 degrees. Under heavy load and high temperature conditions, it is recommended to use all-effect gear oil of 120 degrees |

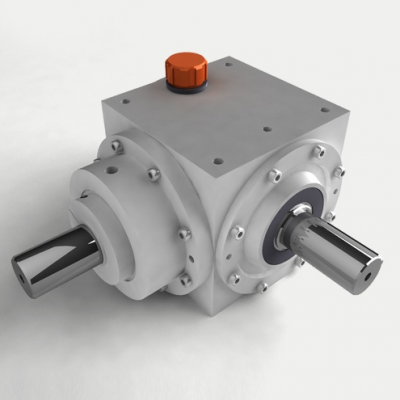

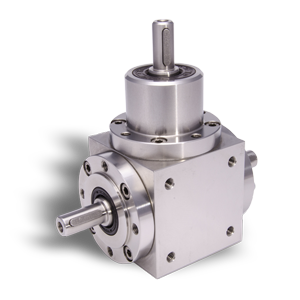

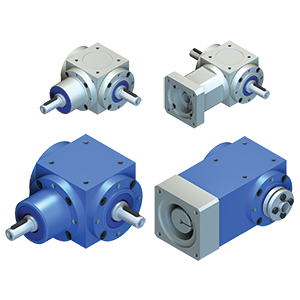

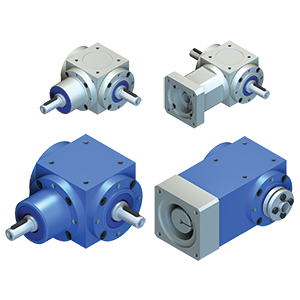

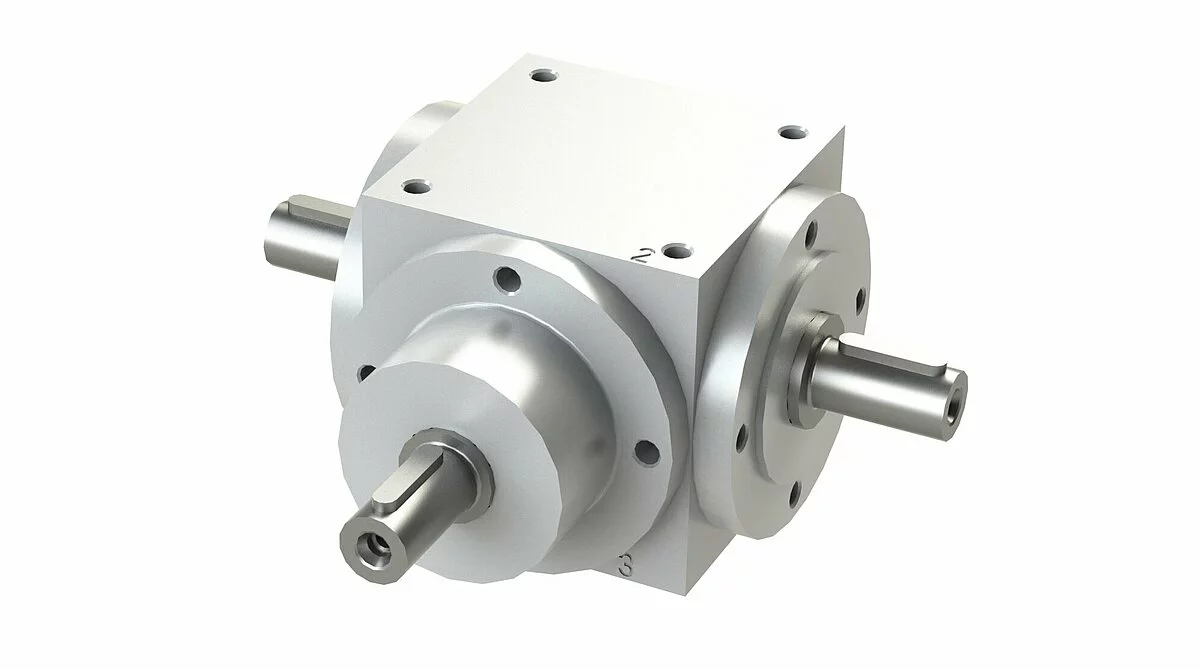

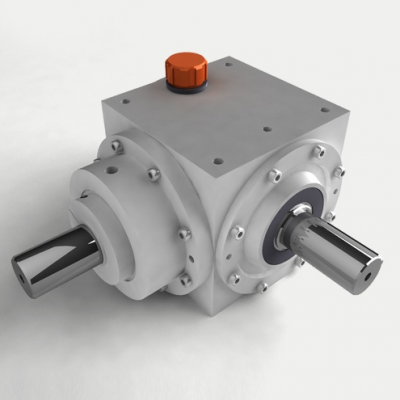

| Product Description | The T series spiral bevel gear steering gearbox is widely used in food, pharmaceutical, chemical, steel, metallurgy, textile, plastic, paper and other machinery equipment, assembly lines and other industries |

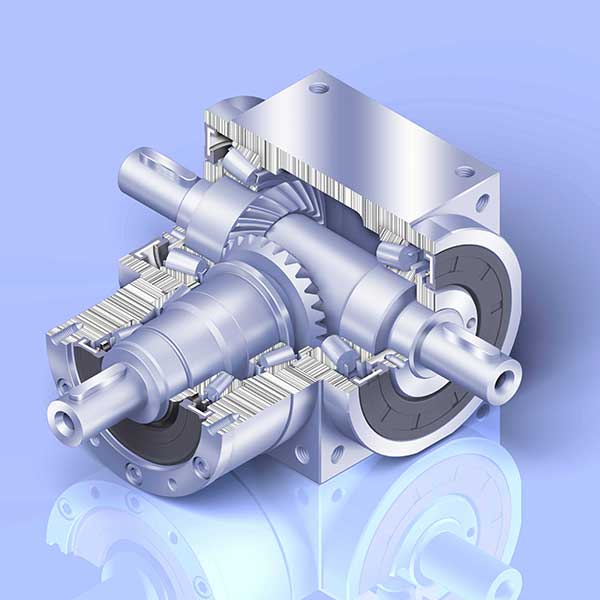

| Technical Features | The gearbox has a high rigidity FC-25 cast iron casing. The gears are made of high-quality high-purity alloy steel 20CrMnTi carburized and quenched, and ground. The shaft is tempered alloy steel with high load-bearing capacity. It is equipped with a heavy load-bearing tapered roller bearing. The oil seal has a double lip seal, which has dustproof and oil leakage prevention capabilities |

| Performance Features | The T series spiral bevel gear steering gearbox is standardized and has many varieties. The speed ratio is all actual transmission ratios, with an average efficiency of 98%. It can run CHINAMFG and reverse, with smooth low-speed or high-speed transmission, low noise, small vibration, and large bearing force |

| Technical Parameters | Speed ratio range: 1/1, 1.5/1, 2/1, 2.5/1, 3/1, 4/1, 5/1. Torque range: 11.2 – 5713 Nm. Power range: 0.014 – 335 kW |

·Product Models: T2, T4, T6, T7, T8, T10, T12, T16, T20, T25, Z2, Z4, Z6, Z7, Z8, Z10, Z12, Z16, Z20, Z25, JRTM2, JRTM4, JRTM6, JRTM7, JRTM8, JRTM10, JRTM12, JRTM16, JRTM20, JRTM25.

·Maintenance: The gearbox should be cleaned internally and the lubricant should be replaced after the initial use of 2 weeks or 100-200 hours. For long-term use, the lubricant should be replaced every half to 1 year or every 1000-2000 hours.

·Lubricant: The product uses China Petroleum’s all-effect gear oil of 90-120 degrees. Under low speed and light load conditions, it is recommended to use all-effect gear oil of 90 degrees. Under heavy load and high temperature conditions, it is recommended to use all-effect gear oil of 120 degrees.

·Product Description: The T series spiral bevel gear steering gearbox is widely used in food, pharmaceutical, chemical, steel, metallurgy, textile, plastic, paper and other machinery equipment, assembly lines and other industries.

·Technical Features: The gearbox has a high rigidity FC-25 cast iron casing. The gears are made of high-quality high-purity alloy steel 20CrMnTi carburized and quenched, and ground. The shaft is tempered alloy steel with high load-bearing capacity. It is equipped with a heavy load-bearing tapered roller bearing. The oil seal has a double lip seal, which has dustproof and oil leakage prevention capabilities.

·Performance Features: The T series spiral bevel gear steering gearbox is standardized and has many varieties. The speed ratio is all actual transmission ratios, with an average efficiency of 98%. It can run CHINAMFG and reverse, with smooth low-speed or high-speed transmission, low noise, small vibration, and large bearing force.

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Coaxial |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Three-Step |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | |

|---|

Contribution of Spiral Bevel Gearboxes to Mechanical System Efficiency

Spiral bevel gearboxes play a crucial role in enhancing the overall efficiency of mechanical systems by:

- Power Transmission: Spiral bevel gearboxes efficiently transmit power between non-parallel and intersecting shafts, allowing mechanical systems to transfer rotational motion with minimal energy loss.

- High Efficiency: The unique tooth geometry of spiral bevel gears ensures smooth and continuous contact between gear teeth, resulting in higher mechanical efficiency compared to other types of gearboxes.

- Optimized Torque Distribution: Spiral bevel gearboxes distribute torque uniformly across the gear teeth, minimizing the concentration of stress and wear on specific teeth. This leads to improved load-sharing capabilities and reduced mechanical losses.

- Reduced Friction and Heat Generation: The rolling action of spiral bevel gears reduces sliding friction, minimizing heat generation and energy losses that often occur in sliding contact gear systems.

- Noise and Vibration Reduction: The meshing of spiral bevel gears generates less noise and vibration compared to other gear types, resulting in smoother and quieter operation.

- Compact Design: Spiral bevel gearboxes can be designed with a compact form factor, allowing for efficient utilization of space in various mechanical systems.

- Customizable Ratios: Gear ratios in spiral bevel gearboxes can be tailored to specific application requirements, ensuring optimal speed and torque matching.

- Reliable Power Transfer: Spiral bevel gears’ robust design and accurate tooth meshing contribute to reliable power transfer even under varying loads and operating conditions.

- Long Service Life: Properly designed and maintained spiral bevel gearboxes exhibit high durability and wear resistance, contributing to extended service life.

By effectively transmitting power, optimizing torque distribution, reducing friction, and providing smooth and reliable operation, spiral bevel gearboxes significantly enhance the overall efficiency of mechanical systems in various industries.

Selecting a Spiral Bevel Gearbox: Key Considerations

Choosing the right spiral bevel gearbox for a specific application requires careful evaluation of various factors:

- Load Requirements: Determine the torque and load demands of the application to select a gearbox with an appropriate torque rating.

- Speed Range: Consider the desired speed range and ensure that the gearbox can handle the required speeds without compromising efficiency or durability.

- Environmental Conditions: Evaluate the operating environment, including temperature, humidity, and presence of dust or debris, to select suitable materials and sealing mechanisms.

- Mounting and Space Constraints: Assess available space and mounting requirements to ensure that the gearbox can be properly integrated into the machinery.

- Efficiency and Power Loss: Evaluate the gearbox’s efficiency to minimize energy loss and optimize power transmission.

- Noise and Vibration: Consider noise and vibration levels to ensure smooth and quiet operation, especially in applications where low noise is crucial.

- Maintenance and Serviceability: Choose a gearbox that is easy to maintain and service, with accessible lubrication points and inspection covers.

- Budget: Balance the required features and performance with the available budget for the gearbox.

- Manufacturer Reputation: Select a reputable manufacturer with a history of producing high-quality spiral bevel gearboxes.

By carefully evaluating these factors and collaborating with gearbox experts, you can make an informed decision and select a spiral bevel gearbox that meets the specific needs of your application.

Differences Between Spiral Bevel Gearboxes and Other Gearbox Types

Spiral bevel gearboxes differ from other gearbox types in several key aspects:

- Gear Tooth Design: Spiral bevel gearboxes use spiral bevel gears with angled teeth, which allow for smoother meshing and reduced impact compared to straight bevel gears. In contrast, other gearbox types might use spur gears, helical gears, or worm gears, each with distinct tooth profiles.

- Shaft Arrangement: Spiral bevel gearboxes have intersecting input and output shafts set at right angles. This enables power transmission between shafts that are not aligned. Other gearbox types, such as parallel shaft gearboxes, have shafts that are parallel to each other.

- Direction Changes: Spiral bevel gearboxes are well-suited for applications requiring direction changes between input and output shafts due to their perpendicular shaft arrangement. Worm gearboxes, on the other hand, are commonly used for large speed reductions and right-angle drives.

- High Torque Transmission: Spiral bevel gearboxes offer high torque transmission capabilities due to the larger contact area of their gear teeth. Planetary gearboxes, while also capable of handling high torque, have a different gear arrangement involving sun, planet, and ring gears.

- Noise and Vibration: Spiral bevel gearboxes tend to produce less noise and vibration compared to straight bevel gearboxes, thanks to their spiral tooth design. Helical gearboxes, which also use angled teeth, offer similar advantages in terms of noise reduction.

- Applications: Spiral bevel gearboxes are commonly used in automotive differentials, aerospace systems, and heavy machinery. Other gearbox types find applications in various industries based on their unique characteristics and advantages.

Overall, the distinctive features of spiral bevel gearboxes set them apart from other gearbox types, making them suitable for specific applications where direction changes, torque transmission, and smooth operation are critical factors.

editor by CX 2023-09-21

China Custom Optimized Thermal Efficiency T Series Spiral Bevel Gear Steering Gearbox with Good quality

Product Description

| Product Features | Description |

| Product Models | T2, T4, T6, T7, T8, T10, T12, T16, T20, T25, Z2, Z4, Z6, Z7, Z8, Z10, Z12, Z16, Z20, Z25, JRTM2, JRTM4, JRTM6, JRTM7, JRTM8, JRTM10, JRTM12, JRTM16, JRTM20, JRTM25 |

| Maintenance | Clean internally and replace lubricant after initial use of 2 weeks or 100-200 hours. For long-term use, replace lubricant every half to 1 year or every 1000-2000 hours |

| Lubricant | China Petroleum’s all-effect gear oil of 90-120 degrees. Under low speed and light load conditions, it is recommended to use all-effect gear oil of 90 degrees. Under heavy load and high temperature conditions, it is recommended to use all-effect gear oil of 120 degrees |

| Product Description | The T series spiral bevel gear steering gearbox is widely used in food, pharmaceutical, chemical, steel, metallurgy, textile, plastic, paper and other machinery equipment, assembly lines and other industries |

| Technical Features | The gearbox has a high rigidity FC-25 cast iron casing. The gears are made of high-quality high-purity alloy steel 20CrMnTi carburized and quenched, and ground. The shaft is tempered alloy steel with high load-bearing capacity. It is equipped with a heavy load-bearing tapered roller bearing. The oil seal has a double lip seal, which has dustproof and oil leakage prevention capabilities |

| Performance Features | The T series spiral bevel gear steering gearbox is standardized and has many varieties. The speed ratio is all actual transmission ratios, with an average efficiency of 98%. It can run CHINAMFG and reverse, with smooth low-speed or high-speed transmission, low noise, small vibration, and large bearing force |

| Technical Parameters | Speed ratio range: 1/1, 1.5/1, 2/1, 2.5/1, 3/1, 4/1, 5/1. Torque range: 11.2 – 5713 Nm. Power range: 0.014 – 335 kW |

·Product Models: T2, T4, T6, T7, T8, T10, T12, T16, T20, T25, Z2, Z4, Z6, Z7, Z8, Z10, Z12, Z16, Z20, Z25, JRTM2, JRTM4, JRTM6, JRTM7, JRTM8, JRTM10, JRTM12, JRTM16, JRTM20, JRTM25.

·Maintenance: The gearbox should be cleaned internally and the lubricant should be replaced after the initial use of 2 weeks or 100-200 hours. For long-term use, the lubricant should be replaced every half to 1 year or every 1000-2000 hours.

·Lubricant: The product uses China Petroleum’s all-effect gear oil of 90-120 degrees. Under low speed and light load conditions, it is recommended to use all-effect gear oil of 90 degrees. Under heavy load and high temperature conditions, it is recommended to use all-effect gear oil of 120 degrees.

·Product Description: The T series spiral bevel gear steering gearbox is widely used in food, pharmaceutical, chemical, steel, metallurgy, textile, plastic, paper and other machinery equipment, assembly lines and other industries.

·Technical Features: The gearbox has a high rigidity FC-25 cast iron casing. The gears are made of high-quality high-purity alloy steel 20CrMnTi carburized and quenched, and ground. The shaft is tempered alloy steel with high load-bearing capacity. It is equipped with a heavy load-bearing tapered roller bearing. The oil seal has a double lip seal, which has dustproof and oil leakage prevention capabilities.

·Performance Features: The T series spiral bevel gear steering gearbox is standardized and has many varieties. The speed ratio is all actual transmission ratios, with an average efficiency of 98%. It can run CHINAMFG and reverse, with smooth low-speed or high-speed transmission, low noise, small vibration, and large bearing force.

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Coaxial |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Three-Step |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | |

|---|

Role of Spiral Bevel Gearboxes in Automotive and Aerospace Industries

Automotive Industry: Spiral bevel gearboxes have significant roles in the automotive sector:

a. Differential Systems: In vehicles, spiral bevel gearboxes are a key component of the differential system. They enable the distribution of torque between the left and right wheels while allowing them to rotate at different speeds during turns. This improves stability, traction, and maneuverability.

b. Transmissions: Spiral bevel gearboxes are also used in some manual transmissions. They help in transferring power and torque efficiently between the engine and the wheels, contributing to smooth gear shifting and overall vehicle performance.

c. Power Steering: In power steering systems, spiral bevel gearboxes assist in translating the rotational movement of the steering wheel into lateral movement of the wheels. This makes steering easier for the driver.

Aerospace Industry: In the aerospace sector, spiral bevel gearboxes have crucial roles:

a. Landing Gear Systems: Aircraft landing gear systems use spiral bevel gearboxes to control the extension and retraction of landing gear during takeoff and landing. These gearboxes ensure precise and synchronized movement, contributing to safe landings and takeoffs.

b. Flight Control Systems: Spiral bevel gearboxes are used in flight control systems to translate pilot inputs into controlled movements of control surfaces such as ailerons, elevators, and rudders. They ensure accurate and responsive control of the aircraft.

c. Engine Accessory Drives: Some aircraft engines utilize spiral bevel gearboxes to transfer power from the engine to various accessories such as generators, hydraulic pumps, and compressors. These gearboxes ensure efficient power distribution and operation of essential systems.

Spiral bevel gearboxes are crucial in both the automotive and aerospace industries, contributing to vehicle performance, safety, and overall functionality.

Materials for Manufacturing Spiral Bevel Gearboxes

Spiral bevel gearboxes are typically constructed using a variety of materials to ensure durability, strength, and reliable performance. Commonly used materials include:

- Steel Alloys: High-quality steel alloys, such as alloy steels or carburizing steels, are commonly used due to their excellent combination of strength, wear resistance, and toughness.

- Bronze Alloys: Bronze alloys, often used for gear teeth and bushings, offer good friction properties and self-lubricating characteristics.

- Cast Iron: Cast iron can be used for the housing or casing of spiral bevel gearboxes due to its excellent damping properties and resistance to wear and corrosion.

- Aluminum Alloys: In some cases, lightweight aluminum alloys are used to construct certain components of the gearbox to reduce overall weight.

- Stainless Steel: Stainless steel may be employed for components exposed to corrosive environments or for applications requiring high levels of cleanliness.

- Heat-Treated Steels: Heat treatment processes like case hardening, quenching, and tempering can enhance the hardness and strength of gear components.

The choice of material depends on factors such as the intended application, load conditions, operating environment, and the specific performance requirements of the gearbox.

Industries Using Spiral Bevel Gearboxes

Spiral bevel gearboxes find applications across various industries where precise power transmission, high torque capacity, and efficient motion transfer are essential. Some of the industries that commonly utilize spiral bevel gearboxes include:

- Automotive: Spiral bevel gears are used in automotive differentials, axles, and steering systems to transmit power efficiently and handle changing loads and directions.

- Aerospace: Aerospace applications require reliable and lightweight power transmission, making spiral bevel gears suitable for aircraft engines, landing gear, and control systems.

- Heavy Machinery: Industries like construction, mining, and agriculture use spiral bevel gearboxes in equipment such as excavators, bulldozers, tractors, and loaders.

- Manufacturing: Spiral bevel gears play a role in industrial machinery, conveyors, robotics, and machine tools, ensuring precise motion and power distribution.

- Marine: Marine propulsion systems and steering mechanisms benefit from the robustness and efficiency of spiral bevel gears.

- Energy: Spiral bevel gearboxes are used in power generation equipment, including wind turbines, hydroelectric generators, and gas turbines.

- Railways: Trains rely on spiral bevel gears in their transmission systems and bogie assemblies to deliver power and maintain stability.

The versatility, durability, and reliable performance of spiral bevel gearboxes make them a valuable component in various industrial sectors.

editor by CX 2023-09-18

China supplier Miter Gear Box or Right Angle Gear Box of Spiral Bevel Gears with High Efficiency High Power Rating. Use in Transmission Truing and Torque Linear Stretch. gearbox adjustment

Product Description

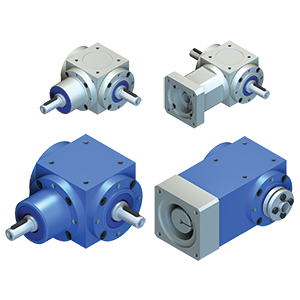

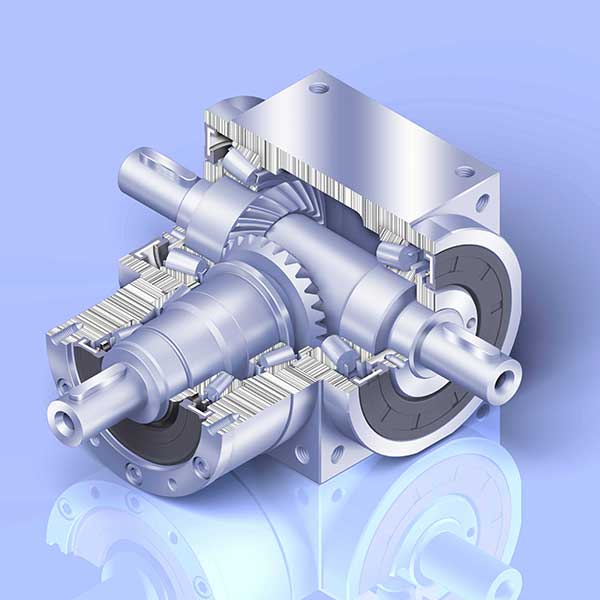

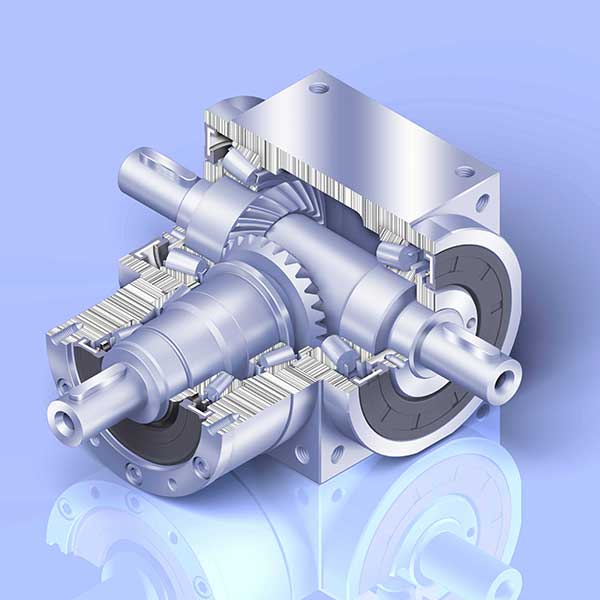

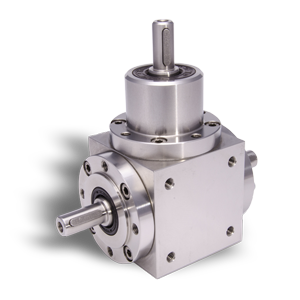

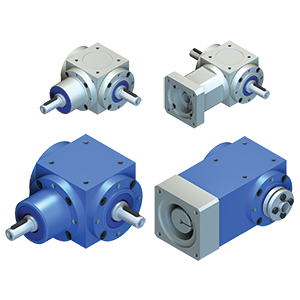

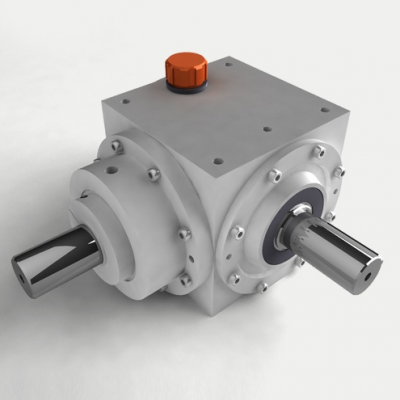

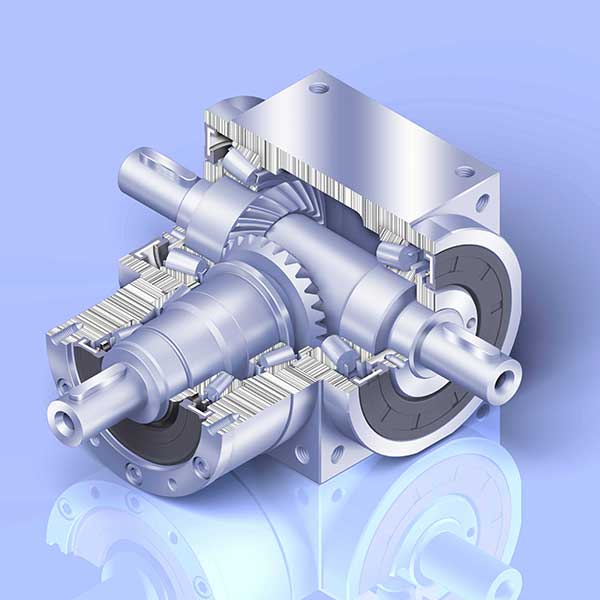

Miter Gear Box or Right angle gear box of spiral bevel gears with high efficiency high power rating. Miter Gear Box extended use in transmission truing and torque linear stretch. Installed in multi-surfaces form 1 shafts to 4 shafts or flange type. bevel gearboxes will be used if the operating direction is to be displaced by 90°. Thus, the output torque can be increased many times. Low-noise and smooth operation, Suitable for manual and electrical operation, Top quality corrosion protection, Stainless steel input shaft. Bevel Gears are used exclusively to transmit rotary motion between intersecting shafts. Through commonly seen in right angle drives, bevel gears can be cut to drive any angle.

How Does A Compact Bevel Gearbox Work?

Compact Cubic Gearboxes Videos For Customers Orders

* Malaysia customers bevel 90 degree gearbox 1:1 ratio at 36567X3, registered Capital 500000CNY) is a leading manufacturer and supplier of Screw Jacks (Mechanical Actuators), Bevel Gearboxes, Lifting Systems, Electric Linear Actuators, Gearmotors and Speed Reducers, and Others Linear Motion and Power Transmission Products in China. We are Alibaba, Made-In-China and SGS (Serial NO.: QIP-ASI192186) audited manufacturer and supplier. We also have a strict quality system, with senior engineers, experienced skilled workers and practiced sales teams, we consistently provide the high quality equipments to meet the customers electro-mechanical actuation, lifting and positioning needs. CHINAMFG Industry guarantees quality, reliability, performance and value for today’s demanding industrial applications.

Website (English): screw-jacks

Website (English): screw-jacks

Website (Chinese): screw-jacks

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Bottle Capping, Food Processing Equipment |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Right Angle Drive |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type and Vertical Type |

| Step: | Single-Step |

| Customization: |

Available

| Customized Request |

|---|

Precision Applications of Spiral Bevel Gearboxes

Spiral bevel gearboxes are well-suited for precision applications that require accurate and controlled motion. Here’s how they can be used in precision settings:

1. Automotive Manufacturing: Spiral bevel gearboxes play a critical role in automotive assembly lines, where precision is essential for proper alignment and fit of components. They help in controlling robotic arms, conveyors, and tool movements with high accuracy.

2. Aerospace Industry: In the aerospace sector, precision is paramount. Spiral bevel gearboxes are used in various applications, including aircraft landing gear systems, where they enable controlled and accurate movement during takeoff and landing.

3. Medical Equipment: Medical devices, such as robotic surgical systems and imaging equipment, require precise and reliable motion control. Spiral bevel gearboxes ensure accurate positioning and movement in these critical applications.

4. Semiconductor Manufacturing: The semiconductor industry demands extreme precision for the fabrication of microchips. Spiral bevel gearboxes are used in equipment like lithography machines, ensuring precise alignment and motion during the manufacturing process.

5. Optics and Instrumentation: Precision optics, telescopes, and scientific instruments require accurate adjustments and controlled movement. Spiral bevel gearboxes provide the necessary motion control for alignment and focusing.

6. Laboratory Automation: In research laboratories, spiral bevel gearboxes are utilized in robotic systems and automated equipment to handle delicate tasks with precision.

Thanks to their high-precision capabilities, spiral bevel gearboxes contribute to improved accuracy, repeatability, and reliability in a wide range of applications where precise motion control is critical.

Selecting a Spiral Bevel Gearbox: Key Considerations

Choosing the right spiral bevel gearbox for a specific application requires careful evaluation of various factors:

- Load Requirements: Determine the torque and load demands of the application to select a gearbox with an appropriate torque rating.

- Speed Range: Consider the desired speed range and ensure that the gearbox can handle the required speeds without compromising efficiency or durability.

- Environmental Conditions: Evaluate the operating environment, including temperature, humidity, and presence of dust or debris, to select suitable materials and sealing mechanisms.

- Mounting and Space Constraints: Assess available space and mounting requirements to ensure that the gearbox can be properly integrated into the machinery.

- Efficiency and Power Loss: Evaluate the gearbox’s efficiency to minimize energy loss and optimize power transmission.

- Noise and Vibration: Consider noise and vibration levels to ensure smooth and quiet operation, especially in applications where low noise is crucial.

- Maintenance and Serviceability: Choose a gearbox that is easy to maintain and service, with accessible lubrication points and inspection covers.

- Budget: Balance the required features and performance with the available budget for the gearbox.

- Manufacturer Reputation: Select a reputable manufacturer with a history of producing high-quality spiral bevel gearboxes.

By carefully evaluating these factors and collaborating with gearbox experts, you can make an informed decision and select a spiral bevel gearbox that meets the specific needs of your application.

Variations in Design of Spiral Bevel Gearboxes for Specific Tasks

Spiral bevel gearboxes can be customized and designed with specific features to suit different tasks and applications. These variations in design allow them to meet the diverse requirements of various industries:

- High-Speed Applications: Spiral bevel gearboxes designed for high-speed applications may feature optimized tooth profiles and precision manufacturing to minimize noise and vibration at elevated rotational speeds.

- Heavy-Duty Applications: Gearboxes intended for heavy-duty tasks, such as industrial machinery and mining equipment, might have reinforced housing, larger bearings, and increased load-carrying capacity to withstand higher loads and provide extended durability.

- Compact Designs: In cases where space is limited, compact spiral bevel gearboxes can be engineered to provide high torque output while maintaining a smaller footprint.

- Specialized Industries: Some industries, like aerospace and defense, may require spiral bevel gearboxes with specific material selections, precision engineering, and reduced weight to meet stringent performance and reliability standards.

- Custom Ratios: Gearboxes with custom gear ratios can be designed for applications that demand specific speed reduction or increase requirements.

By tailoring the design of spiral bevel gearboxes to meet the unique demands of different tasks and industries, manufacturers can ensure optimal performance and longevity in a wide range of applications.

editor by CX 2023-09-15

China Hot selling Continuous Improvement Philosophy T Series Spiral Bevel Gear Steering Gearbox with Great quality

Product Description

| Product Features | Description |

| Product Models | T2, T4, T6, T7, T8, T10, T12, T16, T20, T25, Z2, Z4, Z6, Z7, Z8, Z10, Z12, Z16, Z20, Z25, JRTM2, JRTM4, JRTM6, JRTM7, JRTM8, JRTM10, JRTM12, JRTM16, JRTM20, JRTM25 |

| Maintenance | Clean internally and replace lubricant after initial use of 2 weeks or 100-200 hours. For long-term use, replace lubricant every half to 1 year or every 1000-2000 hours |

| Lubricant | China Petroleum’s all-effect gear oil of 90-120 degrees. Under low speed and light load conditions, it is recommended to use all-effect gear oil of 90 degrees. Under heavy load and high temperature conditions, it is recommended to use all-effect gear oil of 120 degrees |

| Product Description | The T series spiral bevel gear steering gearbox is widely used in food, pharmaceutical, chemical, steel, metallurgy, textile, plastic, paper and other machinery equipment, assembly lines and other industries |

| Technical Features | The gearbox has a high rigidity FC-25 cast iron casing. The gears are made of high-quality high-purity alloy steel 20CrMnTi carburized and quenched, and ground. The shaft is tempered alloy steel with high load-bearing capacity. It is equipped with a heavy load-bearing tapered roller bearing. The oil seal has a double lip seal, which has dustproof and oil leakage prevention capabilities |

| Performance Features | The T series spiral bevel gear steering gearbox is standardized and has many varieties. The speed ratio is all actual transmission ratios, with an average efficiency of 98%. It can run CHINAMFG and reverse, with smooth low-speed or high-speed transmission, low noise, small vibration, and large bearing force |

| Technical Parameters | Speed ratio range: 1/1, 1.5/1, 2/1, 2.5/1, 3/1, 4/1, 5/1. Torque range: 11.2 – 5713 Nm. Power range: 0.014 – 335 kW |

·Product Models: T2, T4, T6, T7, T8, T10, T12, T16, T20, T25, Z2, Z4, Z6, Z7, Z8, Z10, Z12, Z16, Z20, Z25, JRTM2, JRTM4, JRTM6, JRTM7, JRTM8, JRTM10, JRTM12, JRTM16, JRTM20, JRTM25.

·Maintenance: The gearbox should be cleaned internally and the lubricant should be replaced after the initial use of 2 weeks or 100-200 hours. For long-term use, the lubricant should be replaced every half to 1 year or every 1000-2000 hours.

·Lubricant: The product uses China Petroleum’s all-effect gear oil of 90-120 degrees. Under low speed and light load conditions, it is recommended to use all-effect gear oil of 90 degrees. Under heavy load and high temperature conditions, it is recommended to use all-effect gear oil of 120 degrees.

·Product Description: The T series spiral bevel gear steering gearbox is widely used in food, pharmaceutical, chemical, steel, metallurgy, textile, plastic, paper and other machinery equipment, assembly lines and other industries.

·Technical Features: The gearbox has a high rigidity FC-25 cast iron casing. The gears are made of high-quality high-purity alloy steel 20CrMnTi carburized and quenched, and ground. The shaft is tempered alloy steel with high load-bearing capacity. It is equipped with a heavy load-bearing tapered roller bearing. The oil seal has a double lip seal, which has dustproof and oil leakage prevention capabilities.

·Performance Features: The T series spiral bevel gear steering gearbox is standardized and has many varieties. The speed ratio is all actual transmission ratios, with an average efficiency of 98%. It can run CHINAMFG and reverse, with smooth low-speed or high-speed transmission, low noise, small vibration, and large bearing force.

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Coaxial |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Three-Step |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | |

|---|

Assembly and Disassembly of Spiral Bevel Gearboxes

Assembly: The process of assembling spiral bevel gearboxes involves several steps:

a. Preparing Components: Gather all the required components, including gears, bearings, shafts, and housing.

b. Gear Placement: Place the spiral bevel gears onto the designated shafts, ensuring proper alignment and meshing of the gear teeth.

c. Bearing Installation: Install the bearings onto the shafts to support the rotating components. Ensure correct positioning and fit.

d. Housing Alignment: Carefully position the gearbox housing and ensure proper alignment with the shafts and gears.

e. Sealing: Install seals and gaskets to prevent lubricant leakage and maintain internal cleanliness.

f. Fastening: Secure the housing using bolts, ensuring even torque distribution for a stable assembly.

Disassembly: The disassembly process is performed in reverse order:

a. Housing Removal: Start by removing the housing bolts and separating the housing from the internals.

b. Bearing Removal: Remove the bearings from the shafts using suitable tools and techniques.

c. Gear Removal: Carefully slide the gears off the shafts, taking note of their orientation and alignment.

d. Component Inspection: Inspect all components for wear, damage, or signs of fatigue that may require replacement.

e. Cleaning: Thoroughly clean all parts, ensuring the removal of dirt, debris, and old lubricants.

f. Reassembly: Reassemble the gearbox components, following the correct sequence and ensuring proper alignment and meshing.

g. Lubrication: Apply the appropriate lubricant to the gears, bearings, and other moving parts.

h. Housing Fastening: Reattach the housing and tighten the bolts to the specified torque.

i. Functional Testing: Perform functional tests to ensure smooth rotation, proper gear engagement, and no abnormal noises.

Both assembly and disassembly require precision and careful attention to detail to maintain the performance and reliability of spiral bevel gearboxes.

Extending the Lifespan of Spiral Bevel Gearboxes through Maintenance

To ensure the longevity of spiral bevel gearboxes, the following maintenance practices are essential:

- Regular Inspection: Conduct routine visual and functional inspections to identify wear, damage, or anomalies.

- Lubrication: Maintain proper lubrication by using recommended oils or greases. Regularly check oil levels and quality.

- Cleaning: Keep the gearbox clean and free from debris or contaminants that can accelerate wear.

- Tightening and Alignment: Periodically check and tighten bolts, ensuring proper alignment and reducing vibration.

- Temperature Monitoring: Monitor operating temperatures to prevent overheating, which can lead to premature wear.

- Vibration Analysis: Implement vibration analysis to detect potential issues and abnormal wear patterns.

- Seal Inspection: Inspect seals for leaks and damage, as proper sealing prevents contaminants from entering the gearbox.

- Replacement of Worn Parts: Replace worn or damaged components promptly to prevent further deterioration.

- Gear Tooth Inspection: Regularly assess gear tooth condition and contact patterns to detect wear and misalignment.

- Professional Maintenance: Engage qualified technicians for more in-depth inspections, adjustments, and maintenance.

By adhering to these maintenance practices, operators can extend the lifespan of spiral bevel gearboxes, ensure optimal performance, and minimize the risk of unexpected failures.

Spiral Bevel Gearbox: Function and Operation

A spiral bevel gearbox is a type of gearbox that utilizes spiral bevel gears to transmit motion and power between intersecting shafts. It is commonly used in applications where direction changes and high torque transmission are required.

The operation of a spiral bevel gearbox involves the following key aspects:

- Gear Design: Spiral bevel gears have teeth that are cut at an angle, allowing for smoother meshing and quieter operation compared to straight bevel gears. The spiral angle on the gear teeth also facilitates gradual engagement, reducing shock loads.

- Intersecting Shafts: The input and output shafts of a spiral bevel gearbox are positioned at right angles to each other. This configuration allows the gearbox to transmit motion and power between shafts that are not aligned.

- High Torque Capacity: Spiral bevel gears have a larger contact area compared to straight bevel gears, resulting in higher torque transmission capabilities. This makes spiral bevel gearboxes suitable for applications requiring heavy loads and torque.

- Smooth Operation: The spiral tooth design minimizes tooth-to-tooth impact, reducing vibration and noise during gear engagement. This results in smoother operation and improved overall gearbox performance.

- Lubrication: Proper lubrication is essential for the smooth operation and longevity of spiral bevel gearboxes. Lubricating oil is used to reduce friction and heat generation between gear teeth.

- Applications: Spiral bevel gearboxes are used in various industries, including automotive, aerospace, marine, and industrial machinery. They are commonly found in differentials, rear-wheel drives, and heavy machinery.

The unique design of spiral bevel gears allows for efficient power transmission and motion conversion while minimizing noise and ensuring smooth operation.

editor by CX 2023-09-14

China factory K Series Spiral Bevel Gear Decelerator Belt Conveyor Gearbox with Hot selling

Product Description

PROFESSIONAL MANUFACTURE

— SINCE 1995

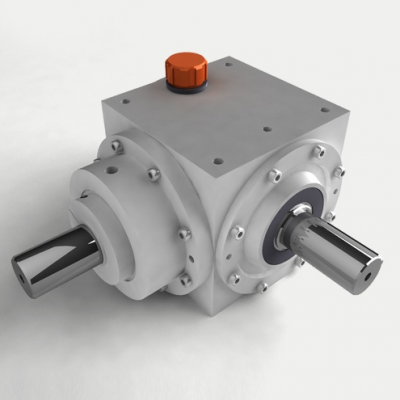

K Series spiral bevel gear decelerator belt conveyor gearbox

Chinese electric motor speed reducer is widely used in mining machinery, chemical industry,steel metallurgy, light

industry,environmental protection, paper making, printing, lifting transport, food industry and so on.

Main Series Product: R series helical gear motor reducer, K series spiral bevel gear reducer, NGW, P series planetary gear reducer, H B series helical gearbox, Z (ZDY, ZLY, ZSY, and ZFY) serial hard tooth surface cylindrical gearbox reducer, D (DBY and DCY) serial hard tooth surface cone gear reducer, cycloidal speed reducer, etc. Meanwhile, map sample processing business can be undertaken

Product Description

It realized serialization and modularization with compact structure and wide range of transmission ratio.

The transmission efficiency reach up to 96%.

The gear processed by Carburizing, Nitriding & Grinding.

High efficiency, superior performance with less energy consumption.

High precision gear, steady transmission, low noise, large load capacity, long service life.

Support various of installation method.

Product Parameters

|

Size |

K 47 57 |

K 67 |

K 77 |

K 87 |

K 97 |

K 107 |

K 127 |

K 157 |

K 167 187 |

|

Structure |

K KA KF KAF KAZ KAT KAB |

||||||||

|

Input power rating(kw) |

0.18-5.5 |

0.18-5.5 |

0.37-11 |

0.75-22 |

3-45 |

7.5-90 |

5.5-55KW |

11-160 |

18.5-200 |

|

Ratio |

6.57-145.14 |

7.14-144.79 |

7.24-192.18 |

7.19-197.37 |

8.95-176.05 |

8.68-146.07 |

12.65-150.41 |

5.00-163.31 |

17.27-180.78 |

|

Permissible torque N.m |

400/600 |

820 |

1550 |

2700 |

4300 |

8000 |

13000 |

1000 |

32000/50000 |

Model selection for washing machine Gear Box Transmission:

Closely using the ideal reduction ratio.

Reduction ratio = servo motor speed / reducer output shaft speed

Torque calculation: Torque calculation is very important for the life of reducer, and pay attention to whether the maximum torque value (TP) of acceleration exceeds the maximum load torque of the reducer.

The applicable power is usually the applicable power of the servo models on the market, the applicability of the reducer is very high, the working coefficient can be maintained above 1.2, but the choice can also be based on their own needs to decide. industrial helical gearbox. H PV series High quality Right Angle Unique speed reducer HB helical gearbox / gear box.

Detailed Photos

Chinese Speed Reducer/industrial helical gearbox is a mechanical transmission in many fields of the national economy. The product categories covered by the industry include all kinds of gear reducer, planetary gear reducer and worm reducer, as well as various special transmission devices such as speed increasing device, speed control Devices, including various types of flexible transmission devices, such as compound transmission. Products and services in the field of metallurgy, nonferrous metals, coal, building materials, ships, water conservancy, electricity, construction machinery and petrochemical industries.

In all fields of national economy and national defense industry, gearbox products have a wide range of applications. Food light industry, electric machinery, construction machinery, metallurgy machinery, cement machinery, environmental protection machinery, electronic appliances, road construction machinery, water conservancy machinery, chemical machinery, mining machinery, conveyor machinery, building materials machinery, rubber machinery, petroleum machinery and other industries have strong demand of Reducer products.

Packaging & Shipping

Application

| Driven machines | |||

| Waste water treatment | Thickeners,filter presses,flocculation apparata,aerators,raking equipment,combined longitudinal and rotary rakes,pre-thickeners,screw pumps,water turbines,centrifugal pumps | Dredgers | Bucket conveyors, dumping devices, carterpillar travelling gears, bucket wheel excavators as pick up, bucket wheel excavator for primitive material, cutter head, traversing gears |

| Chemical industry | Plate bending machines, extruders, dough mills, rubbers calenders, cooling drums, mixers for uniform media, agitators for media with uniform density, toasters, centrifuges | Metal working mills | plate tilters, ingot pushers, winding machines, cooling bed transfer frames, roller straigheners, table continuous intermittent, roller tables reversing tube mills, shears continuous, casting drivers, reversing CZPT mills |

| Metal working mills | Reversing slabbing mills. reversing wire mills, reversing sheet mills, reversing plate mill, roll adjustment drives | Conveyors | Bucket conveyors, hauling winches, hoists, belt conveyors, good lifts, passenger lifts, apron conveyors, escalators, rail travlling gears |

| Frequency converters | Reciprocating compressors | ||

| Cranes | Slewing gears, luffing gears, travelling gears, hoisting gear, derricking jib cranes | Cooling towers | Cooling tower fans, blowers axial and radial |

| Cane sugar production | Cane knives, cane mills | Beet sugar production | Beet cossettes macerators, extraction plants, mechanical refrigerators, juice boilers, sugar beet washing machines, sugar beet cutter |

| Paper machines | Pulper drives | Cableways | Material ropeways, continuous ropeway |

| Cement industry | Concrete mixer, breaker, rotary kilns, tube mills, separators, roll crushers | ||

Company Profile

Established in 1995 , HangZhou Boji Machinery is a professional manufacturer and exporter that is concerned with the design, development and production of Gearbox Speed Reducer. We are located in HangZhou of ZheJiang Province, with convenient transportation access. With our own brand “TianQi”, all of our products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world.

Our company possesses complete machining center, lathe, gear shaping machine, gear milling machine, gear grinding machine and assembling lines. Our well-equipped facilities and excellent quality control throughout all stages of production enables us to guarantee total customer satisfaction.

Besides, In 2005,we attained ISO9001 certification. As a result of our high quality products and outstanding customer service, we have gained a global sales network CZPT South America, Saudi Arabia, Vietnam, Pakistan, Philippines, South Africa and other countries and regions.

With rich export experience, high quality products, competitive prices, good service and in-time delivery, we certain that we can meet all of your requirement and exceed your expectations. Our feature is bright with new cooperative relationships with companies from all over the world. We look CZPT to speaking with you to future discuss how we can be of service to you.

FAQ

1. Who are we?

We are the Factory, with over 25 years of production experience, based in ZheJiang , China, start from 1995,sell to Domestic Market(50.00%),Mid East(10.00%),Southeast Asia(10.00%),Western Europe(5.00%),South America(5.00%),Eastern Europe(5.00%),Eastern Asia(5.00%),North America(3.00%),Africa(2.00%),Southern Europe(2.00%),South Asia(2.00%),Central America(1.00%).

2. Can you customize according to our requirements?

Yes, we can design nonstandard products according to customer’s drawing and sample.

3.What can you buy from us?

speed reducer,gearbox,gear motor,pump,crusher

4. Why should you buy from us not from other suppliers?

Founded in 1995, with over 20 years of production experience and credibility. With professional engineer team, advanced technology production and skilled workers.Specialized in the production of reducer. Map sample processing business can be undertaken.

5. What services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,DDP,DDU,Express Delivery;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,Credit Card,PayPal,Western Union,Cash;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Hindi,Italian

|

Shipping Cost:

Estimated freight per unit. |

To be negotiated |

|---|

| Application: | Motor, Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Samples: |

US$ 600/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

Role of Spiral Bevel Gearboxes in Automotive and Aerospace Industries

Automotive Industry: Spiral bevel gearboxes have significant roles in the automotive sector:

a. Differential Systems: In vehicles, spiral bevel gearboxes are a key component of the differential system. They enable the distribution of torque between the left and right wheels while allowing them to rotate at different speeds during turns. This improves stability, traction, and maneuverability.

b. Transmissions: Spiral bevel gearboxes are also used in some manual transmissions. They help in transferring power and torque efficiently between the engine and the wheels, contributing to smooth gear shifting and overall vehicle performance.

c. Power Steering: In power steering systems, spiral bevel gearboxes assist in translating the rotational movement of the steering wheel into lateral movement of the wheels. This makes steering easier for the driver.

Aerospace Industry: In the aerospace sector, spiral bevel gearboxes have crucial roles:

a. Landing Gear Systems: Aircraft landing gear systems use spiral bevel gearboxes to control the extension and retraction of landing gear during takeoff and landing. These gearboxes ensure precise and synchronized movement, contributing to safe landings and takeoffs.

b. Flight Control Systems: Spiral bevel gearboxes are used in flight control systems to translate pilot inputs into controlled movements of control surfaces such as ailerons, elevators, and rudders. They ensure accurate and responsive control of the aircraft.

c. Engine Accessory Drives: Some aircraft engines utilize spiral bevel gearboxes to transfer power from the engine to various accessories such as generators, hydraulic pumps, and compressors. These gearboxes ensure efficient power distribution and operation of essential systems.

Spiral bevel gearboxes are crucial in both the automotive and aerospace industries, contributing to vehicle performance, safety, and overall functionality.

Selecting a Spiral Bevel Gearbox: Key Considerations

Choosing the right spiral bevel gearbox for a specific application requires careful evaluation of various factors:

- Load Requirements: Determine the torque and load demands of the application to select a gearbox with an appropriate torque rating.

- Speed Range: Consider the desired speed range and ensure that the gearbox can handle the required speeds without compromising efficiency or durability.

- Environmental Conditions: Evaluate the operating environment, including temperature, humidity, and presence of dust or debris, to select suitable materials and sealing mechanisms.

- Mounting and Space Constraints: Assess available space and mounting requirements to ensure that the gearbox can be properly integrated into the machinery.

- Efficiency and Power Loss: Evaluate the gearbox’s efficiency to minimize energy loss and optimize power transmission.

- Noise and Vibration: Consider noise and vibration levels to ensure smooth and quiet operation, especially in applications where low noise is crucial.

- Maintenance and Serviceability: Choose a gearbox that is easy to maintain and service, with accessible lubrication points and inspection covers.

- Budget: Balance the required features and performance with the available budget for the gearbox.

- Manufacturer Reputation: Select a reputable manufacturer with a history of producing high-quality spiral bevel gearboxes.

By carefully evaluating these factors and collaborating with gearbox experts, you can make an informed decision and select a spiral bevel gearbox that meets the specific needs of your application.

Torque and Load Distribution in Spiral Bevel Gearboxes

Spiral bevel gearboxes are designed to efficiently handle torque and distribute loads across their gear teeth. The unique geometry of spiral bevel gears contributes to their capability in managing torque and load distribution:

- Interlocking Teeth: Spiral bevel gears have curved teeth that gradually engage and disengage as they rotate. This design allows for smoother contact between the gears, reducing abrupt torque spikes and load shocks.

- Multiple Contact Points: The spiral teeth provide multiple contact points along the gear tooth profile. This distributed contact helps spread the load evenly, minimizing concentrated stress points.

- High Tooth Engagement: The meshing of spiral bevel gears involves a significant amount of tooth engagement, ensuring that the load is distributed over a larger area of the gear teeth.

- Optimized Tooth Profile: The tooth profile of spiral bevel gears is designed to maintain consistent contact as the gears rotate. This optimized profile contributes to even load distribution.

- Precision Manufacturing: Spiral bevel gears are manufactured with high precision, ensuring accurate gear tooth profiles and minimal deviations. This precision results in uniform load distribution.

Overall, the interplay of these design features allows spiral bevel gearboxes to effectively manage torque and load distribution, leading to reliable and efficient power transmission.

editor by CX 2023-09-08

China Standard Robust Safety Features T Series Spiral Bevel Gear Steering Gearbox for Personnel Protection with Great quality

Product Description

| Product Features | Description |

| Product Models | T2, T4, T6, T7, T8, T10, T12, T16, T20, T25, Z2, Z4, Z6, Z7, Z8, Z10, Z12, Z16, Z20, Z25, JRTM2, JRTM4, JRTM6, JRTM7, JRTM8, JRTM10, JRTM12, JRTM16, JRTM20, JRTM25 |

| Maintenance | Clean internally and replace lubricant after initial use of 2 weeks or 100-200 hours. For long-term use, replace lubricant every half to 1 year or every 1000-2000 hours |

| Lubricant | China Petroleum’s all-effect gear oil of 90-120 degrees. Under low speed and light load conditions, it is recommended to use all-effect gear oil of 90 degrees. Under heavy load and high temperature conditions, it is recommended to use all-effect gear oil of 120 degrees |

| Product Description | The T series spiral bevel gear steering gearbox is widely used in food, pharmaceutical, chemical, steel, metallurgy, textile, plastic, paper and other machinery equipment, assembly lines and other industries |

| Technical Features | The gearbox has a high rigidity FC-25 cast iron casing. The gears are made of high-quality high-purity alloy steel 20CrMnTi carburized and quenched, and ground. The shaft is tempered alloy steel with high load-bearing capacity. It is equipped with a heavy load-bearing tapered roller bearing. The oil seal has a double lip seal, which has dustproof and oil leakage prevention capabilities |

| Performance Features | The T series spiral bevel gear steering gearbox is standardized and has many varieties. The speed ratio is all actual transmission ratios, with an average efficiency of 98%. It can run CZPT and reverse, with smooth low-speed or high-speed transmission, low noise, small vibration, and large bearing force |

| Technical Parameters | Speed ratio range: 1/1, 1.5/1, 2/1, 2.5/1, 3/1, 4/1, 5/1. Torque range: 11.2 – 5713 Nm. Power range: 0.014 – 335 kW |

·Product Models: T2, T4, T6, T7, T8, T10, T12, T16, T20, T25, Z2, Z4, Z6, Z7, Z8, Z10, Z12, Z16, Z20, Z25, JRTM2, JRTM4, JRTM6, JRTM7, JRTM8, JRTM10, JRTM12, JRTM16, JRTM20, JRTM25.

·Maintenance: The gearbox should be cleaned internally and the lubricant should be replaced after the initial use of 2 weeks or 100-200 hours. For long-term use, the lubricant should be replaced every half to 1 year or every 1000-2000 hours.

·Lubricant: The product uses China Petroleum’s all-effect gear oil of 90-120 degrees. Under low speed and light load conditions, it is recommended to use all-effect gear oil of 90 degrees. Under heavy load and high temperature conditions, it is recommended to use all-effect gear oil of 120 degrees.

·Product Description: The T series spiral bevel gear steering gearbox is widely used in food, pharmaceutical, chemical, steel, metallurgy, textile, plastic, paper and other machinery equipment, assembly lines and other industries.

·Technical Features: The gearbox has a high rigidity FC-25 cast iron casing. The gears are made of high-quality high-purity alloy steel 20CrMnTi carburized and quenched, and ground. The shaft is tempered alloy steel with high load-bearing capacity. It is equipped with a heavy load-bearing tapered roller bearing. The oil seal has a double lip seal, which has dustproof and oil leakage prevention capabilities.

·Performance Features: The T series spiral bevel gear steering gearbox is standardized and has many varieties. The speed ratio is all actual transmission ratios, with an average efficiency of 98%. It can run CZPT and reverse, with smooth low-speed or high-speed transmission, low noise, small vibration, and large bearing force.

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Coaxial |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Three-Step |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | |

|---|

Assembly and Disassembly of Spiral Bevel Gearboxes

Assembly: The process of assembling spiral bevel gearboxes involves several steps:

a. Preparing Components: Gather all the required components, including gears, bearings, shafts, and housing.

b. Gear Placement: Place the spiral bevel gears onto the designated shafts, ensuring proper alignment and meshing of the gear teeth.

c. Bearing Installation: Install the bearings onto the shafts to support the rotating components. Ensure correct positioning and fit.

d. Housing Alignment: Carefully position the gearbox housing and ensure proper alignment with the shafts and gears.

e. Sealing: Install seals and gaskets to prevent lubricant leakage and maintain internal cleanliness.

f. Fastening: Secure the housing using bolts, ensuring even torque distribution for a stable assembly.

Disassembly: The disassembly process is performed in reverse order:

a. Housing Removal: Start by removing the housing bolts and separating the housing from the internals.

b. Bearing Removal: Remove the bearings from the shafts using suitable tools and techniques.

c. Gear Removal: Carefully slide the gears off the shafts, taking note of their orientation and alignment.

d. Component Inspection: Inspect all components for wear, damage, or signs of fatigue that may require replacement.

e. Cleaning: Thoroughly clean all parts, ensuring the removal of dirt, debris, and old lubricants.

f. Reassembly: Reassemble the gearbox components, following the correct sequence and ensuring proper alignment and meshing.

g. Lubrication: Apply the appropriate lubricant to the gears, bearings, and other moving parts.

h. Housing Fastening: Reattach the housing and tighten the bolts to the specified torque.

i. Functional Testing: Perform functional tests to ensure smooth rotation, proper gear engagement, and no abnormal noises.

Both assembly and disassembly require precision and careful attention to detail to maintain the performance and reliability of spiral bevel gearboxes.

Precision in Spiral Bevel Gear Tooth Profile Design

Manufacturers employ advanced techniques to ensure precision in the design of spiral bevel gear tooth profiles:

- Computer-Aided Design (CAD): Design engineers use CAD software to create accurate tooth profiles, considering factors like gear ratio, tooth contact, and load distribution.

- Finite Element Analysis (FEA): FEA simulations analyze stress distribution, deformation, and contact patterns to optimize tooth profiles for strength and durability.

- Manufacturing Precision: Modern manufacturing methods, such as CNC machining and grinding, ensure tight tolerances and accurate tooth profiles.

- Gear Cutting: Gleason or Klingelnberg gear cutting machines produce precise gear tooth profiles by using specialized cutting tools and controlled processes.

- Tooth Surface Inspection: Manufacturers employ advanced measuring equipment to verify tooth geometry, profile accuracy, and alignment.

- Contact Pattern Analysis: Before finalizing the design, contact pattern simulations help optimize tooth engagement for even load distribution.

- Material Selection: Choosing suitable materials with excellent dimensional stability further enhances tooth profile precision.

By leveraging these techniques and technologies, manufacturers can ensure the precision and quality of spiral bevel gear tooth profiles, resulting in efficient power transmission and reduced wear.

Spiral Bevel Gearbox: Function and Operation

A spiral bevel gearbox is a type of gearbox that utilizes spiral bevel gears to transmit motion and power between intersecting shafts. It is commonly used in applications where direction changes and high torque transmission are required.

The operation of a spiral bevel gearbox involves the following key aspects:

- Gear Design: Spiral bevel gears have teeth that are cut at an angle, allowing for smoother meshing and quieter operation compared to straight bevel gears. The spiral angle on the gear teeth also facilitates gradual engagement, reducing shock loads.

- Intersecting Shafts: The input and output shafts of a spiral bevel gearbox are positioned at right angles to each other. This configuration allows the gearbox to transmit motion and power between shafts that are not aligned.

- High Torque Capacity: Spiral bevel gears have a larger contact area compared to straight bevel gears, resulting in higher torque transmission capabilities. This makes spiral bevel gearboxes suitable for applications requiring heavy loads and torque.

- Smooth Operation: The spiral tooth design minimizes tooth-to-tooth impact, reducing vibration and noise during gear engagement. This results in smoother operation and improved overall gearbox performance.

- Lubrication: Proper lubrication is essential for the smooth operation and longevity of spiral bevel gearboxes. Lubricating oil is used to reduce friction and heat generation between gear teeth.

- Applications: Spiral bevel gearboxes are used in various industries, including automotive, aerospace, marine, and industrial machinery. They are commonly found in differentials, rear-wheel drives, and heavy machinery.

The unique design of spiral bevel gears allows for efficient power transmission and motion conversion while minimizing noise and ensuring smooth operation.

editor by CX 2023-09-04

China factory 90 Degree Helical Gear Reduction Box Right Angle Spiral Bevel Gearbox with Motor cvt gearbox

Product Description

PROFESSIONAL MANUFACTURE

— SINCE 1995

90 degree helical gear reduction box right angle spiral bevel gearbox with motor

Chinese electric motor speed reducer is widely used in mining machinery, chemical industry,steel metallurgy, light

industry,environmental protection, paper making, printing, lifting transport, food industry and so on.

Main Series Product: R series helical gear motor reducer, K series spiral bevel gear reducer, NGW, P series planetary gear reducer, H B series helical gearbox, Z (ZDY, ZLY, ZSY, and ZFY) serial hard tooth surface cylindrical gearbox reducer, D (DBY and DCY) serial hard tooth surface cone gear reducer, cycloidal speed reducer, etc. Meanwhile, map sample processing business can be undertaken.

Product Description

It realized serialization and modularization with compact structure and wide range of transmission ratio.

The transmission efficiency reach up to 96%.

The gear processed by Carburizing, Nitriding & Grinding.

High efficiency, superior performance with less energy consumption.

High precision gear, steady transmission, low noise, large load capacity, long service life.

Support various of installation method.

Product Parameters

|

Size |

K 47 57 |

K 67 |

K 77 |

K 87 |

K 97 |

K 107 |

K 127 |

K 157 |

K 167 187 |

|

Structure |

K KA KF KAF KAZ KAT KAB |

||||||||

|

Input power rating(kw) |

0.18-5.5 |

0.18-5.5 |

0.37-11 |

0.75-22 |

3-45 |

7.5-90 |

5.5-55KW |

11-160 |

18.5-200 |

|

Ratio |

6.57-145.14 |

7.14-144.79 |

7.24-192.18 |

7.19-197.37 |

8.95-176.05 |

8.68-146.07 |

12.65-150.41 |

5.00-163.31 |

17.27-180.78 |

|

Permissible torque N.m |

400/600 |

820 |

1550 |

2700 |

4300 |

8000 |

13000 |

1000 |

32000/50000 |

Model selection for washing machine Gear Box Transmission:

Closely using the ideal reduction ratio.

Reduction ratio = servo motor speed / reducer output shaft speed

Torque calculation: Torque calculation is very important for the life of reducer, and pay attention to whether the maximum torque value (TP) of acceleration exceeds the maximum load torque of the reducer.

The applicable power is usually the applicable power of the servo models on the market, the applicability of the reducer is very high, the working coefficient can be maintained above 1.2, but the choice can also be based on their own needs to decide. industrial helical gearbox. H PV series High quality Right Angle Unique speed reducer HB helical gearbox / gear box.

Detailed Photos

Chinese Speed Reducer/industrial helical gearbox is a mechanical transmission in many fields of the national economy. The product categories covered by the industry include all kinds of gear reducer, planetary gear reducer and worm reducer, as well as various special transmission devices such as speed increasing device, speed control Devices, including various types of flexible transmission devices, such as compound transmission. Products and services in the field of metallurgy, nonferrous metals, coal, building materials, ships, water conservancy, electricity, construction machinery and petrochemical industries.

In all fields of national economy and national defense industry, gearbox products have a wide range of applications. Food light industry, electric machinery, construction machinery, metallurgy machinery, cement machinery, environmental protection machinery, electronic appliances, road construction machinery, water conservancy machinery, chemical machinery, mining machinery, conveyor machinery, building materials machinery, rubber machinery, petroleum machinery and other industries have strong demand of Reducer products.

Packaging & Shipping

Application

| Driven machines | |||

| Waste water treatment | Thickeners,filter presses,flocculation apparata,aerators,raking equipment,combined longitudinal and rotary rakes,pre-thickeners,screw pumps,water turbines,centrifugal pumps | Dredgers | Bucket conveyors, dumping devices, carterpillar travelling gears, bucket wheel excavators as pick up, bucket wheel excavator for primitive material, cutter head, traversing gears |

| Chemical industry | Plate bending machines, extruders, dough mills, rubbers calenders, cooling drums, mixers for uniform media, agitators for media with uniform density, toasters, centrifuges | Metal working mills | plate tilters, ingot pushers, winding machines, cooling bed transfer frames, roller straigheners, table continuous intermittent, roller tables reversing tube mills, shears continuous, casting drivers, reversing CZPT mills |

| Metal working mills | Reversing slabbing mills. reversing wire mills, reversing sheet mills, reversing plate mill, roll adjustment drives | Conveyors | Bucket conveyors, hauling winches, hoists, belt conveyors, good lifts, passenger lifts, apron conveyors, escalators, rail travlling gears |

| Frequency converters | Reciprocating compressors | ||

| Cranes | Slewing gears, luffing gears, travelling gears, hoisting gear, derricking jib cranes | Cooling towers | Cooling tower fans, blowers axial and radial |

| Cane sugar production | Cane knives, cane mills | Beet sugar production | Beet cossettes macerators, extraction plants, mechanical refrigerators, juice boilers, sugar beet washing machines, sugar beet cutter |

| Paper machines | Pulper drives | Cableways | Material ropeways, continuous ropeway |

| Cement industry | Concrete mixer, breaker, rotary kilns, tube mills, separators, roll crushers | ||

Company Profile

Established in 1995 , HangZhou Boji Machinery is a professional manufacturer and exporter that is concerned with the design, development and production of Gearbox Speed Reducer. We are located in HangZhou of ZheJiang Province, with convenient transportation access. With our own brand “TianQi”, all of our products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world.

Our company possesses complete machining center, lathe, gear shaping machine, gear milling machine, gear grinding machine and assembling lines. Our well-equipped facilities and excellent quality control throughout all stages of production enables us to guarantee total customer satisfaction.

Besides, In 2005,we attained ISO9001 certification. As a result of our high quality products and outstanding customer service, we have gained a global sales network CZPT South America, Saudi Arabia, Vietnam, Pakistan, Philippines, South Africa and other countries and regions.

With rich export experience, high quality products, competitive prices, good service and in-time delivery, we certain that we can meet all of your requirement and exceed your expectations. Our feature is bright with new cooperative relationships with companies from all over the world. We look CZPT to speaking with you to future discuss how we can be of service to you.

FAQ

1. Who are we?

We are the Factory, with over 25 years of production experience, based in ZheJiang , China, start from 1995,sell to Domestic Market(50.00%),Mid East(10.00%),Southeast Asia(10.00%),Western Europe(5.00%),South America(5.00%),Eastern Europe(5.00%),Eastern Asia(5.00%),North America(3.00%),Africa(2.00%),Southern Europe(2.00%),South Asia(2.00%),Central America(1.00%).

2. Can you customize according to our requirements?

Yes, we can design nonstandard products according to customer’s drawing and sample.

3.What can you buy from us?

speed reducer,gearbox,gear motor,pump,crusher

4. Why should you buy from us not from other suppliers?

Founded in 1995, with over 20 years of production experience and credibility. With professional engineer team, advanced technology production and skilled workers.Specialized in the production of reducer. Map sample processing business can be undertaken.

5. What services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,DDP,DDU,Express Delivery;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,Credit Card,PayPal,Western Union,Cash;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Hindi,Italian

|

Shipping Cost:

Estimated freight per unit. |

To be negotiated |

|---|

| Application: | Motor, Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Samples: |

US$ 480/Piece

1 Piece(Min.Order) | Order Sample 90 degree right angle spiral bevel gearbox

|

|---|

| Customization: |

Available

| Customized Request |

|---|

Differences Between Spiral Bevel Gearboxes and Other Gearbox Types

Spiral bevel gearboxes differ from other gearbox types in several key aspects:

- Gear Tooth Design: Spiral bevel gearboxes use spiral bevel gears with angled teeth, which allow for smoother meshing and reduced impact compared to straight bevel gears. In contrast, other gearbox types might use spur gears, helical gears, or worm gears, each with distinct tooth profiles.

- Shaft Arrangement: Spiral bevel gearboxes have intersecting input and output shafts set at right angles. This enables power transmission between shafts that are not aligned. Other gearbox types, such as parallel shaft gearboxes, have shafts that are parallel to each other.

- Direction Changes: Spiral bevel gearboxes are well-suited for applications requiring direction changes between input and output shafts due to their perpendicular shaft arrangement. Worm gearboxes, on the other hand, are commonly used for large speed reductions and right-angle drives.

- High Torque Transmission: Spiral bevel gearboxes offer high torque transmission capabilities due to the larger contact area of their gear teeth. Planetary gearboxes, while also capable of handling high torque, have a different gear arrangement involving sun, planet, and ring gears.

- Noise and Vibration: Spiral bevel gearboxes tend to produce less noise and vibration compared to straight bevel gearboxes, thanks to their spiral tooth design. Helical gearboxes, which also use angled teeth, offer similar advantages in terms of noise reduction.

- Applications: Spiral bevel gearboxes are commonly used in automotive differentials, aerospace systems, and heavy machinery. Other gearbox types find applications in various industries based on their unique characteristics and advantages.

Overall, the distinctive features of spiral bevel gearboxes set them apart from other gearbox types, making them suitable for specific applications where direction changes, torque transmission, and smooth operation are critical factors.

Contribution of Spiral Bevel Gearboxes to Mechanical System Efficiency

Spiral bevel gearboxes play a crucial role in enhancing the overall efficiency of mechanical systems by:

- Power Transmission: Spiral bevel gearboxes efficiently transmit power between non-parallel and intersecting shafts, allowing mechanical systems to transfer rotational motion with minimal energy loss.

- High Efficiency: The unique tooth geometry of spiral bevel gears ensures smooth and continuous contact between gear teeth, resulting in higher mechanical efficiency compared to other types of gearboxes.

- Optimized Torque Distribution: Spiral bevel gearboxes distribute torque uniformly across the gear teeth, minimizing the concentration of stress and wear on specific teeth. This leads to improved load-sharing capabilities and reduced mechanical losses.

- Reduced Friction and Heat Generation: The rolling action of spiral bevel gears reduces sliding friction, minimizing heat generation and energy losses that often occur in sliding contact gear systems.

- Noise and Vibration Reduction: The meshing of spiral bevel gears generates less noise and vibration compared to other gear types, resulting in smoother and quieter operation.

- Compact Design: Spiral bevel gearboxes can be designed with a compact form factor, allowing for efficient utilization of space in various mechanical systems.

- Customizable Ratios: Gear ratios in spiral bevel gearboxes can be tailored to specific application requirements, ensuring optimal speed and torque matching.

- Reliable Power Transfer: Spiral bevel gears’ robust design and accurate tooth meshing contribute to reliable power transfer even under varying loads and operating conditions.

- Long Service Life: Properly designed and maintained spiral bevel gearboxes exhibit high durability and wear resistance, contributing to extended service life.

By effectively transmitting power, optimizing torque distribution, reducing friction, and providing smooth and reliable operation, spiral bevel gearboxes significantly enhance the overall efficiency of mechanical systems in various industries.

editor by CX 2023-09-04

China Hot selling ND Feed Mixer Machines Gearbox with high quality

Product Description

Product Description

|

Item No.: |

P152, Mixer Gearbox |

|

Ratio and Shaft: |

OEM acceptable |

|

Key word |

Agricultural Machinery Gearbox |

Company Profile

In 2571, HangZhou CZPT Machinery Co.,ltd was established by Ms. Iris and her 2 partners(Mr. Tian and Mr. Yang) in HangZhou City, ZHangZhoug province, China, all 3 Founders are engineers who have more than averaged 30 years of experience.

We, CZPT machinery established a complete quality management system and sales service network to provide clients with high-quality products and satisfactory service. Our products are sold in 36 countries and regions in the world, our main market is the European market.

Factory & Workshop

Professional

30 years experience engineman. R&D office, Test laboratory, CNC lathe workshop operated by professionals.

Responsible

2~10years warranty. Attitude determines everything, details determine success or failure. We are responsible for your products.

Scientific management

100% tested. Strict company system and scientific material management will reduce the error rate.

Certifications

We’re working on research and manufacturing all kinds of gearbox reducer and mechanical parts these 11 years, and have obtained certificates including ISO9001, many Gearbox Patents, SGS, BV, etc.

Sample Room

Through our CZPT brand ND, CZPT Machinery delivers agricultural solutions to agriculture machinery manufacturer and distributors CZPT through a full line of spiral bevel / straight bevel / spur gearboxes, drive shafts, sheet metal, hydraulic cylinder, motors, tyre, worm gearboxes, worm operators etc. Products can be customized as request.

FAQ

Q: Are you trading company or manufacturer ?

A: We are exactly a factory.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: How long is your delivery time ? What is your terms of payment ?

A: Generally it is 40-45 days. The time may vary depending on the product and the level of customization. For standard products, the payment is: 30% T/T in advance, balance before shippment.

Q: What is the exact MOQ or price for your product ?

A: As an OEM company, we can provide and adapt our products to a wide range of needs.Thus, MOQ and price may greatly vary with size, material and further specifications; For instance, costly products or standard products will usually have a lower MOQ. Please contact us with all relevant details to get the most accurate quotation.

If you have another question, please feel free to contact us.

| Application: | Machinery, Agricultural Machinery, Mixer |

|---|---|

| Function: | Speed Changing, Speed Reduction, Speed Increase |

| Type: | Gearbox |

| Certificate: | ISO9001, BV, SGS, Gearbox Patents |

| MOQ: | 1 PC |

| Color: | Customized |

| Samples: |

US$ 1500/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Types of Vehicle Gearboxes

In a vehicle, there are many types of gearboxes available. There are planetary gearboxes, Coaxial helical gearboxes, and skew bevel helical gearboxes, among others. In this article, we’ll cover all of them and help you determine which type of gearbox would be right for your vehicle. Also, we’ll discuss how each differs from the others.

planetary gearbox

A planetary gearbox is composed of three main components: a sun gear, an input bevel gear, and an output shaft. A planetary gearbox can have different output torques and ratios. The basic model of a planetary gearbox is highly efficient and transmits 97% of the power input. There are several kinds of planetary gearboxes, depending on the type of operation. In general, there are three types: the simple, the intermediate, and the complex.

The price of a planetary gearbox can vary a lot, and it’s important to know what you’ll need. Different manufacturers produce different planetary gearboxes, so check with a manufacturer to see what they have available. Make sure to check the quality of the planetary gearbox before making a final purchase. In addition, be sure to compare the prices and the availability of a particular product. A quality planetary gearbox will provide years of trouble-free operation and will not break your bank.

Planetary gears feature an integer number of teeth. Each planet has teeth that must mesh with its ring or sun. The number of planets, ring, and tooth count of each gear determine whether the teeth mesh. Some planets have fewer teeth than others, so they mesh better than others. However, compound planets can be more flexible and achieve higher reduction ratios. If you’re looking for a planetary gearbox for your next project, consider getting in touch with a manufacturer who specializes in this technology.