Product Description

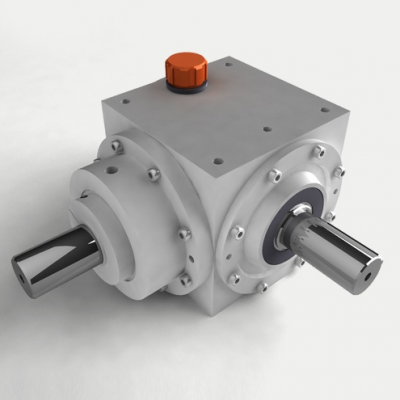

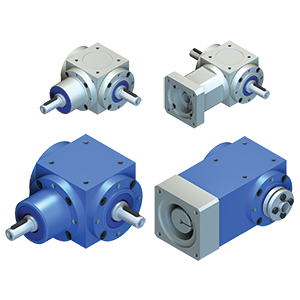

Miter Gear Box or Right angle gear box of spiral bevel gears with high efficiency high power rating. Miter Gear Box extended use in transmission truing and torque linear stretch. Installed in multi-surfaces form 1 shafts to 4 shafts or flange type. bevel gearboxes will be used if the operating direction is to be displaced by 90°. Thus, the output torque can be increased many times. Low-noise and smooth operation, Suitable for manual and electrical operation, Top quality corrosion protection, Stainless steel input shaft. Bevel Gears are used exclusively to transmit rotary motion between intersecting shafts. Through commonly seen in right angle drives, bevel gears can be cut to drive any angle.

How Does A Compact Bevel Gearbox Work?

Compact Cubic Gearboxes Videos For Customers Orders

* Malaysia customers bevel 90 degree gearbox 1:1 ratio at 36567X3, registered Capital 500000CNY) is a leading manufacturer and supplier of Screw Jacks (Mechanical Actuators), Bevel Gearboxes, Lifting Systems, Electric Linear Actuators, Gearmotors and Speed Reducers, and Others Linear Motion and Power Transmission Products in China. We are Alibaba, Made-In-China and SGS (Serial NO.: QIP-ASI192186) audited manufacturer and supplier. We also have a strict quality system, with senior engineers, experienced skilled workers and practiced sales teams, we consistently provide the high quality equipments to meet the customers electro-mechanical actuation, lifting and positioning needs. CHINAMFG Industry guarantees quality, reliability, performance and value for today’s demanding industrial applications.

Website (English): screw-jacks

Website (English): screw-jacks

Website (Chinese): screw-jacks

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Bottle Capping, Food Processing Equipment |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Right Angle Drive |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type and Vertical Type |

| Step: | Single-Step |

| Customization: |

Available

| Customized Request |

|---|

Precision Applications of Spiral Bevel Gearboxes

Spiral bevel gearboxes are well-suited for precision applications that require accurate and controlled motion. Here’s how they can be used in precision settings:

1. Automotive Manufacturing: Spiral bevel gearboxes play a critical role in automotive assembly lines, where precision is essential for proper alignment and fit of components. They help in controlling robotic arms, conveyors, and tool movements with high accuracy.

2. Aerospace Industry: In the aerospace sector, precision is paramount. Spiral bevel gearboxes are used in various applications, including aircraft landing gear systems, where they enable controlled and accurate movement during takeoff and landing.

3. Medical Equipment: Medical devices, such as robotic surgical systems and imaging equipment, require precise and reliable motion control. Spiral bevel gearboxes ensure accurate positioning and movement in these critical applications.

4. Semiconductor Manufacturing: The semiconductor industry demands extreme precision for the fabrication of microchips. Spiral bevel gearboxes are used in equipment like lithography machines, ensuring precise alignment and motion during the manufacturing process.

5. Optics and Instrumentation: Precision optics, telescopes, and scientific instruments require accurate adjustments and controlled movement. Spiral bevel gearboxes provide the necessary motion control for alignment and focusing.

6. Laboratory Automation: In research laboratories, spiral bevel gearboxes are utilized in robotic systems and automated equipment to handle delicate tasks with precision.

Thanks to their high-precision capabilities, spiral bevel gearboxes contribute to improved accuracy, repeatability, and reliability in a wide range of applications where precise motion control is critical.

Selecting a Spiral Bevel Gearbox: Key Considerations

Choosing the right spiral bevel gearbox for a specific application requires careful evaluation of various factors:

- Load Requirements: Determine the torque and load demands of the application to select a gearbox with an appropriate torque rating.

- Speed Range: Consider the desired speed range and ensure that the gearbox can handle the required speeds without compromising efficiency or durability.

- Environmental Conditions: Evaluate the operating environment, including temperature, humidity, and presence of dust or debris, to select suitable materials and sealing mechanisms.

- Mounting and Space Constraints: Assess available space and mounting requirements to ensure that the gearbox can be properly integrated into the machinery.

- Efficiency and Power Loss: Evaluate the gearbox’s efficiency to minimize energy loss and optimize power transmission.

- Noise and Vibration: Consider noise and vibration levels to ensure smooth and quiet operation, especially in applications where low noise is crucial.

- Maintenance and Serviceability: Choose a gearbox that is easy to maintain and service, with accessible lubrication points and inspection covers.

- Budget: Balance the required features and performance with the available budget for the gearbox.

- Manufacturer Reputation: Select a reputable manufacturer with a history of producing high-quality spiral bevel gearboxes.

By carefully evaluating these factors and collaborating with gearbox experts, you can make an informed decision and select a spiral bevel gearbox that meets the specific needs of your application.

Variations in Design of Spiral Bevel Gearboxes for Specific Tasks

Spiral bevel gearboxes can be customized and designed with specific features to suit different tasks and applications. These variations in design allow them to meet the diverse requirements of various industries:

- High-Speed Applications: Spiral bevel gearboxes designed for high-speed applications may feature optimized tooth profiles and precision manufacturing to minimize noise and vibration at elevated rotational speeds.

- Heavy-Duty Applications: Gearboxes intended for heavy-duty tasks, such as industrial machinery and mining equipment, might have reinforced housing, larger bearings, and increased load-carrying capacity to withstand higher loads and provide extended durability.

- Compact Designs: In cases where space is limited, compact spiral bevel gearboxes can be engineered to provide high torque output while maintaining a smaller footprint.

- Specialized Industries: Some industries, like aerospace and defense, may require spiral bevel gearboxes with specific material selections, precision engineering, and reduced weight to meet stringent performance and reliability standards.

- Custom Ratios: Gearboxes with custom gear ratios can be designed for applications that demand specific speed reduction or increase requirements.

By tailoring the design of spiral bevel gearboxes to meet the unique demands of different tasks and industries, manufacturers can ensure optimal performance and longevity in a wide range of applications.

editor by CX 2023-09-15