Product Description

PROFESSIONAL MANUFACTURE

— SINCE 1995

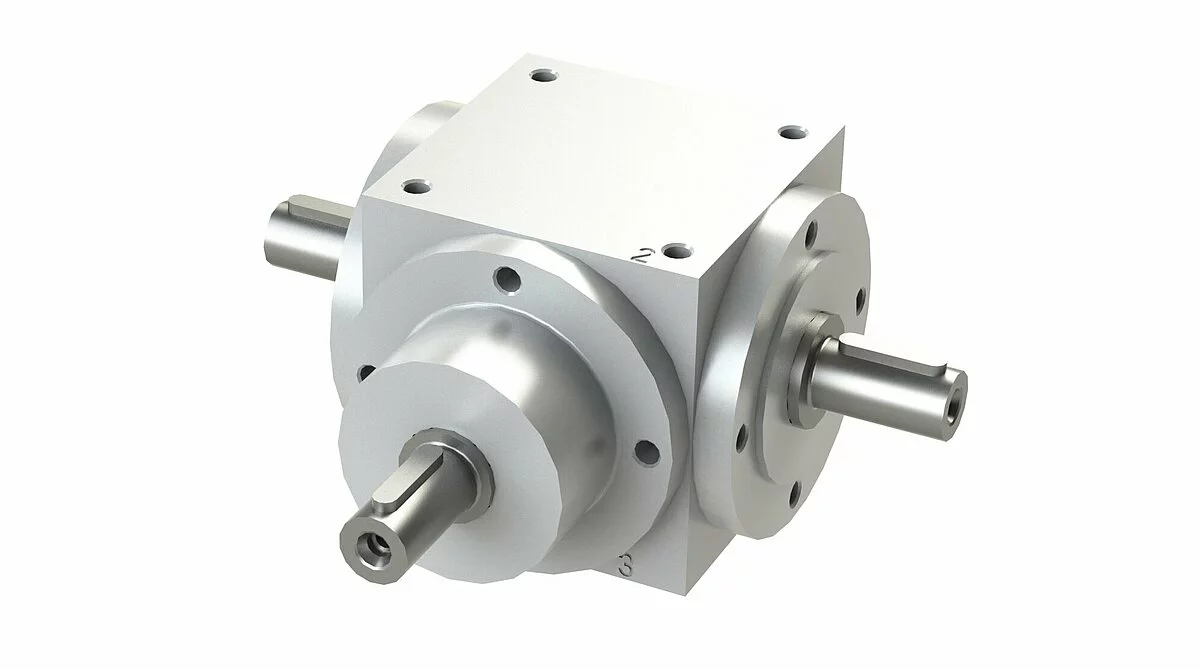

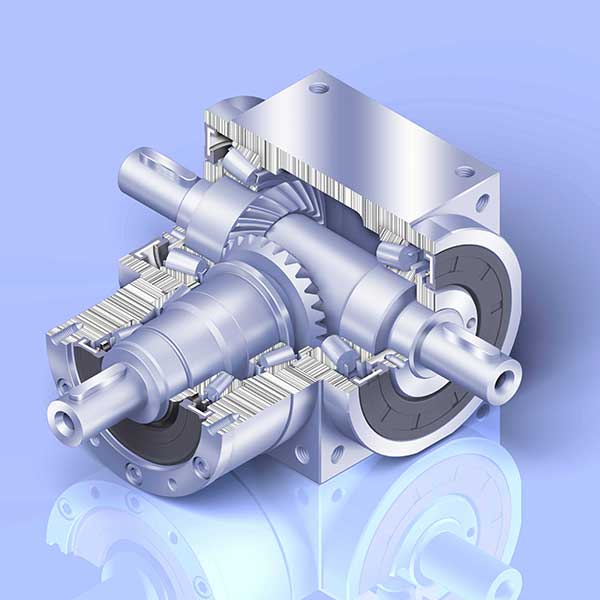

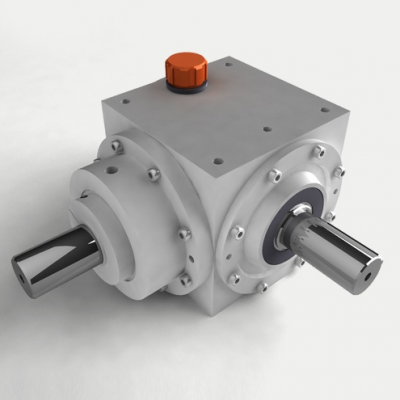

90 degree helical gear reduction box right angle spiral bevel gearbox with motor

Chinese electric motor speed reducer is widely used in mining machinery, chemical industry,steel metallurgy, light

industry,environmental protection, paper making, printing, lifting transport, food industry and so on.

Main Series Product: R series helical gear motor reducer, K series spiral bevel gear reducer, NGW, P series planetary gear reducer, H B series helical gearbox, Z (ZDY, ZLY, ZSY, and ZFY) serial hard tooth surface cylindrical gearbox reducer, D (DBY and DCY) serial hard tooth surface cone gear reducer, cycloidal speed reducer, etc. Meanwhile, map sample processing business can be undertaken.

Product Description

It realized serialization and modularization with compact structure and wide range of transmission ratio.

The transmission efficiency reach up to 96%.

The gear processed by Carburizing, Nitriding & Grinding.

High efficiency, superior performance with less energy consumption.

High precision gear, steady transmission, low noise, large load capacity, long service life.

Support various of installation method.

Product Parameters

|

Size |

K 47 57 |

K 67 |

K 77 |

K 87 |

K 97 |

K 107 |

K 127 |

K 157 |

K 167 187 |

|

Structure |

K KA KF KAF KAZ KAT KAB |

||||||||

|

Input power rating(kw) |

0.18-5.5 |

0.18-5.5 |

0.37-11 |

0.75-22 |

3-45 |

7.5-90 |

5.5-55KW |

11-160 |

18.5-200 |

|

Ratio |

6.57-145.14 |

7.14-144.79 |

7.24-192.18 |

7.19-197.37 |

8.95-176.05 |

8.68-146.07 |

12.65-150.41 |

5.00-163.31 |

17.27-180.78 |

|

Permissible torque N.m |

400/600 |

820 |

1550 |

2700 |

4300 |

8000 |

13000 |

1000 |

32000/50000 |

Model selection for washing machine Gear Box Transmission:

Closely using the ideal reduction ratio.

Reduction ratio = servo motor speed / reducer output shaft speed

Torque calculation: Torque calculation is very important for the life of reducer, and pay attention to whether the maximum torque value (TP) of acceleration exceeds the maximum load torque of the reducer.

The applicable power is usually the applicable power of the servo models on the market, the applicability of the reducer is very high, the working coefficient can be maintained above 1.2, but the choice can also be based on their own needs to decide. industrial helical gearbox. H PV series High quality Right Angle Unique speed reducer HB helical gearbox / gear box.

Detailed Photos

Chinese Speed Reducer/industrial helical gearbox is a mechanical transmission in many fields of the national economy. The product categories covered by the industry include all kinds of gear reducer, planetary gear reducer and worm reducer, as well as various special transmission devices such as speed increasing device, speed control Devices, including various types of flexible transmission devices, such as compound transmission. Products and services in the field of metallurgy, nonferrous metals, coal, building materials, ships, water conservancy, electricity, construction machinery and petrochemical industries.

In all fields of national economy and national defense industry, gearbox products have a wide range of applications. Food light industry, electric machinery, construction machinery, metallurgy machinery, cement machinery, environmental protection machinery, electronic appliances, road construction machinery, water conservancy machinery, chemical machinery, mining machinery, conveyor machinery, building materials machinery, rubber machinery, petroleum machinery and other industries have strong demand of Reducer products.

Packaging & Shipping

Application

| Driven machines | |||

| Waste water treatment | Thickeners,filter presses,flocculation apparata,aerators,raking equipment,combined longitudinal and rotary rakes,pre-thickeners,screw pumps,water turbines,centrifugal pumps | Dredgers | Bucket conveyors, dumping devices, carterpillar travelling gears, bucket wheel excavators as pick up, bucket wheel excavator for primitive material, cutter head, traversing gears |

| Chemical industry | Plate bending machines, extruders, dough mills, rubbers calenders, cooling drums, mixers for uniform media, agitators for media with uniform density, toasters, centrifuges | Metal working mills | plate tilters, ingot pushers, winding machines, cooling bed transfer frames, roller straigheners, table continuous intermittent, roller tables reversing tube mills, shears continuous, casting drivers, reversing CZPT mills |

| Metal working mills | Reversing slabbing mills. reversing wire mills, reversing sheet mills, reversing plate mill, roll adjustment drives | Conveyors | Bucket conveyors, hauling winches, hoists, belt conveyors, good lifts, passenger lifts, apron conveyors, escalators, rail travlling gears |

| Frequency converters | Reciprocating compressors | ||

| Cranes | Slewing gears, luffing gears, travelling gears, hoisting gear, derricking jib cranes | Cooling towers | Cooling tower fans, blowers axial and radial |

| Cane sugar production | Cane knives, cane mills | Beet sugar production | Beet cossettes macerators, extraction plants, mechanical refrigerators, juice boilers, sugar beet washing machines, sugar beet cutter |

| Paper machines | Pulper drives | Cableways | Material ropeways, continuous ropeway |

| Cement industry | Concrete mixer, breaker, rotary kilns, tube mills, separators, roll crushers | ||

Company Profile

Established in 1995 , HangZhou Boji Machinery is a professional manufacturer and exporter that is concerned with the design, development and production of Gearbox Speed Reducer. We are located in HangZhou of ZheJiang Province, with convenient transportation access. With our own brand “TianQi”, all of our products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world.

Our company possesses complete machining center, lathe, gear shaping machine, gear milling machine, gear grinding machine and assembling lines. Our well-equipped facilities and excellent quality control throughout all stages of production enables us to guarantee total customer satisfaction.

Besides, In 2005,we attained ISO9001 certification. As a result of our high quality products and outstanding customer service, we have gained a global sales network CZPT South America, Saudi Arabia, Vietnam, Pakistan, Philippines, South Africa and other countries and regions.

With rich export experience, high quality products, competitive prices, good service and in-time delivery, we certain that we can meet all of your requirement and exceed your expectations. Our feature is bright with new cooperative relationships with companies from all over the world. We look CZPT to speaking with you to future discuss how we can be of service to you.

FAQ

1. Who are we?

We are the Factory, with over 25 years of production experience, based in ZheJiang , China, start from 1995,sell to Domestic Market(50.00%),Mid East(10.00%),Southeast Asia(10.00%),Western Europe(5.00%),South America(5.00%),Eastern Europe(5.00%),Eastern Asia(5.00%),North America(3.00%),Africa(2.00%),Southern Europe(2.00%),South Asia(2.00%),Central America(1.00%).

2. Can you customize according to our requirements?

Yes, we can design nonstandard products according to customer’s drawing and sample.

3.What can you buy from us?

speed reducer,gearbox,gear motor,pump,crusher

4. Why should you buy from us not from other suppliers?

Founded in 1995, with over 20 years of production experience and credibility. With professional engineer team, advanced technology production and skilled workers.Specialized in the production of reducer. Map sample processing business can be undertaken.

5. What services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,DDP,DDU,Express Delivery;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,Credit Card,PayPal,Western Union,Cash;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Hindi,Italian

|

Shipping Cost:

Estimated freight per unit. |

To be negotiated |

|---|

| Application: | Motor, Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Samples: |

US$ 480/Piece

1 Piece(Min.Order) | Order Sample 90 degree right angle spiral bevel gearbox

|

|---|

| Customization: |

Available

| Customized Request |

|---|

Differences Between Spiral Bevel Gearboxes and Other Gearbox Types

Spiral bevel gearboxes differ from other gearbox types in several key aspects:

- Gear Tooth Design: Spiral bevel gearboxes use spiral bevel gears with angled teeth, which allow for smoother meshing and reduced impact compared to straight bevel gears. In contrast, other gearbox types might use spur gears, helical gears, or worm gears, each with distinct tooth profiles.

- Shaft Arrangement: Spiral bevel gearboxes have intersecting input and output shafts set at right angles. This enables power transmission between shafts that are not aligned. Other gearbox types, such as parallel shaft gearboxes, have shafts that are parallel to each other.

- Direction Changes: Spiral bevel gearboxes are well-suited for applications requiring direction changes between input and output shafts due to their perpendicular shaft arrangement. Worm gearboxes, on the other hand, are commonly used for large speed reductions and right-angle drives.

- High Torque Transmission: Spiral bevel gearboxes offer high torque transmission capabilities due to the larger contact area of their gear teeth. Planetary gearboxes, while also capable of handling high torque, have a different gear arrangement involving sun, planet, and ring gears.

- Noise and Vibration: Spiral bevel gearboxes tend to produce less noise and vibration compared to straight bevel gearboxes, thanks to their spiral tooth design. Helical gearboxes, which also use angled teeth, offer similar advantages in terms of noise reduction.

- Applications: Spiral bevel gearboxes are commonly used in automotive differentials, aerospace systems, and heavy machinery. Other gearbox types find applications in various industries based on their unique characteristics and advantages.

Overall, the distinctive features of spiral bevel gearboxes set them apart from other gearbox types, making them suitable for specific applications where direction changes, torque transmission, and smooth operation are critical factors.

Contribution of Spiral Bevel Gearboxes to Mechanical System Efficiency

Spiral bevel gearboxes play a crucial role in enhancing the overall efficiency of mechanical systems by:

- Power Transmission: Spiral bevel gearboxes efficiently transmit power between non-parallel and intersecting shafts, allowing mechanical systems to transfer rotational motion with minimal energy loss.

- High Efficiency: The unique tooth geometry of spiral bevel gears ensures smooth and continuous contact between gear teeth, resulting in higher mechanical efficiency compared to other types of gearboxes.

- Optimized Torque Distribution: Spiral bevel gearboxes distribute torque uniformly across the gear teeth, minimizing the concentration of stress and wear on specific teeth. This leads to improved load-sharing capabilities and reduced mechanical losses.

- Reduced Friction and Heat Generation: The rolling action of spiral bevel gears reduces sliding friction, minimizing heat generation and energy losses that often occur in sliding contact gear systems.

- Noise and Vibration Reduction: The meshing of spiral bevel gears generates less noise and vibration compared to other gear types, resulting in smoother and quieter operation.

- Compact Design: Spiral bevel gearboxes can be designed with a compact form factor, allowing for efficient utilization of space in various mechanical systems.

- Customizable Ratios: Gear ratios in spiral bevel gearboxes can be tailored to specific application requirements, ensuring optimal speed and torque matching.

- Reliable Power Transfer: Spiral bevel gears’ robust design and accurate tooth meshing contribute to reliable power transfer even under varying loads and operating conditions.

- Long Service Life: Properly designed and maintained spiral bevel gearboxes exhibit high durability and wear resistance, contributing to extended service life.

By effectively transmitting power, optimizing torque distribution, reducing friction, and providing smooth and reliable operation, spiral bevel gearboxes significantly enhance the overall efficiency of mechanical systems in various industries.

editor by CX 2023-09-04

China wholesaler Cyclo Drive Gear Motor Speed Reduction Gearbox Supplier Industrial Cycloidal X Wb Series Pin Wheel Miniature Wheel Double Shaft Durable Professional Bw Bwd Bld gearbox assembly

Product Description

Cyclo Drive Gear Motor Speed Reduction Gearbox Supplier Industrial Cycloidal X WB Series Pin Wheel Miniature Wheel Double Shaft Durable Professional BW BWD BlD

X / B series high quality cycloidal gearbox small planetary reducer

Quick Details:

Type: XB series Cycloidal Pin Wheel Speed Reducer

Input Speed: 1000-1500rmp

Output Speed: 0.3-280rpm

Certification: ISO9001 CE

Ex Power:0.09-132KW

Warranty: 1Years

| Product Name | X/B series Cycloidal Pin Wheel Speed Reducer |

| The Gear Material | GCR15 |

| The case Material | Cast Iron |

| Color | Blue,Green, or Customized |

| HS Code | 84834090 |

| Model | X3 |

| Delivery time | 7-10days |

| Brand | TIANGOU |

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Car |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Coaxial |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Three-Step |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

How to Select a Gearbox

When you drive your vehicle, the gearbox provides you with traction and speed. The lower gear provides the most traction, while the higher gear has the most speed. Selecting the right gear for your driving conditions will help you maximize both. The right gearing will vary based on road conditions, load, and speed. Short gearing will accelerate you more quickly, while tall gearing will increase top speed. However, you should understand how to use the gearbox before driving.

Function

The function of the gearbox is to transmit rotational energy to the machine’s drive train. The ratio between input and output torque is the ratio of the torque to the speed of rotation. Gearboxes have many different functions. A gearbox may have multiple functions or one function that is used to drive several other machines. If one gear is not turning, the other will be able to turn the gearbox. This is where the gearbox gets its name.

The pitch-controlled system has an equal number of failure modes as the electrical system, accounting for a large proportion of the longest machine downtime and halt time. The relationship between mechanisms and faults is not easily modeled mathematically. Failure modes of gearboxes are shown in Fig. 3. A gearbox’s true service life is six to eight years. However, a gearbox’s fault detection process must be developed as mature technology is required to reduce the downtime and avoid catastrophic incidents.

A gearbox is a vital piece of machinery. It processes energy produced by an engine to move the machine’s parts. A gearbox’s efficiency depends on how efficiently it transfers energy. The higher the ratio, the more torque is transferred to the wheels. It is a common component of bicycles, cars, and a variety of other devices. Its four major functions include:

In addition to ensuring gearbox reliability, a gearbox’s maintainability should be evaluated in the design phase. Maintainability considerations should be integrated into the gearbox design, such as the type of spare parts available. An appropriate maintenance regime will also determine how often to replace or repair specific parts. A proper maintenance procedure will also ensure that the gearbox is accessible. Whether it is easy to access or difficult to reach, accessibility is essential.

Purpose

A car’s transmission connects the engine to the wheels, allowing a higher-speed crankshaft to provide leverage. High-torque engines are necessary for the vehicle’s starting, acceleration, and meeting road resistance. The gearbox reduces the engine’s speed and provides torque variations at the wheels. The transmission also provides reversing power, making it possible to move the vehicle backwards and forwards.

Gears transmit power from one shaft to another. The size of the gears and number of teeth determine the amount of torque the unit can transmit. A higher gear ratio means more torque, but slower speed. The gearbox’s lever moves the engaging part on the shaft. The lever also slides the gears and synchronizers into place. If the lever slips to the left or right, the engine operates in second gear.

Gearboxes need to be closely monitored to reduce the likelihood of premature failure. Various tests are available to detect defective gear teeth and increase machine reliability. Figure 1.11(a) and (b) show a gearbox with 18 teeth and a 1.5:1 transmission ratio. The input shaft is connected to a sheave and drives a “V” belt. This transmission ratio allows the gearbox to reduce the speed of the motor, while increasing torque and reducing output speed.

When it comes to speed reduction, gear box is the most common method for reducing motor torque. The torque output is directly proportional to the volume of the motor. A small gearbox, for example, can produce as much torque as a large motor with the same output speed. The same holds true for the reverse. There are hybrid drives and in-line gearboxes. Regardless of the type, knowing about the functions of a gearbox will make it easier to choose the right one for your specific application.

Application

When selecting a gearbox, the service factor must be considered. Service factor is the difference between the actual capacity of the gearbox and the value required by the application. Additional requirements for the gearbox may result in premature seal wear or overheating. The service factor should be as low as possible, as it could be the difference between the lifetime of the gearbox and its failure. In some cases, a gearbox’s service factor can be as high as 1.4, which is sufficient for most industrial applications.

China dominates the renewable energy industry, with the largest installed capacity of 1000 gigawatts and more than 2000 terawatt hours of electricity generated each year. The growth in these sectors is expected to increase the demand for gearboxes. For example, in China, wind and hydropower energy production are the major components of wind and solar power plants. The increased installation capacity indicates increased use of gearboxes for these industries. A gearbox that is not suitable for its application will not be functional, which may be detrimental to the production of products in the country.

A gearbox can be mounted in one of four different positions. The first three positions are concentric, parallel, or right angle, and the fourth position is shaft mount. A shaft mount gearbox is typically used in applications where the motor can’t be mounted via a foot. These positions are discussed in more detail below. Choosing the correct gearbox is essential in your business, but remember that a well-designed gearbox will help your bottom line.

The service factor of a gearbox is dependent on the type of load. A high shock load, for example, can cause premature failure of the gear teeth or shaft bearings. In such cases, a higher service factor is required. In other cases, a gearbox that is designed for high shock loads can withstand such loads without deteriorating its performance. Moreover, it will also reduce the cost of maintaining the gearbox over time.

Material

When choosing the material for your gearbox, you must balance the strength, durability, and cost of the design. This article will discuss the different types of materials and their respective applications and power transmission calculations. A variety of alloys are available, each of which offers its own advantages, including improved hardness and wear resistance. The following are some of the common alloys used in gears. The advantage of alloys is their competitive pricing. A gear made from one of these materials is usually stronger than its counterparts.

The carbon content of SPCC prevents the material from hardening like SS. However, thin sheets made from SPCC are often used for gears with lower strength. Because of the low carbon content, SPCC’s surface doesn’t harden as quickly as SS gears do, so soft nitriding is needed to provide hardness. However, if you want a gear that won’t rust, then you should consider SS or FCD.

In addition to cars, gearboxes are also used in the aerospace industry. They are used in space travel and are used in airplane engines. In agriculture, they are used in irrigation, pest and insect control machinery, and plowing machines. They are also used in construction equipment like cranes, bulldozers, and tractors. Gearboxes are also used in the food processing industry, including conveyor systems, kilns, and packaging machinery.

The teeth of the gears in your gearbox are important when it comes to performance. A properly meshing gear will allow the gears to achieve peak performance and withstand torque. Gear teeth are like tiny levers, and effective meshing reduces stress and slippage. A stationary parametric analysis will help you determine the quality of meshing throughout the gearing cycle. This method is often the most accurate way to determine whether your gears are meshing well.

Manufacturing

The global gear market is divided into five key regions, namely, North America, Europe, Asia Pacific, and Latin America. Among these regions, Asia Pacific is expected to generate the largest GDP, owing to rapidly growing energy demand and investments in industrial infrastructure. This region is also home to some of the largest manufacturing bases, and its continuous building of new buildings and homes will support the industry’s growth. In terms of application, gearboxes are used in construction, agricultural machinery, and transportation.

The Industrial Gearbox market is anticipated to expand during the next several years, driven by the rapid growth of the construction industry and business advancements. However, there are several challenges that hamper the growth of the industry. These include the high cost of operations and maintenance of gear units. This report covers the market size of industrial gearboxes globally, as well as their manufacturing technologies. It also includes manufacturer data for the period of 2020-2024. The report also features a discussion of market drivers and restraints.

Global health crisis and decreasing seaborne commerce have moderately adverse effects on the industry. Falling seaborne commerce has created a barrier to investment. The value of international crude oil is expected to cross USD 0 by April 2020, putting an end to new assets development and exploitation. In such a scenario, the global gearbox market will face many challenges. However, the opportunities are huge. So, the market for industrial gearboxes is expected to grow by more than 6% by 2020, thanks to the increasing number of light vehicles sold in the country.

The main shaft of a gearbox, also known as the output shaft, spins at different speeds and transfers torque to an automobile. The output shaft is splined so that a coupler and gear can be connected to it. The counter shaft and primary shaft are supported by bearings, which reduce friction in the spinning element. Another important part of a gearbox is the gears, which vary in tooth count. The number of teeth determines how much torque a gear can transfer. In addition, the gears can glide in any position.

editor by CX 2023-06-08

China OEM China Factory Travel Gear Reduction TM10 Final Drive Motor Gearbox For Excavator with high quality

Product Description

China Factory Travel Gear Reduction TM10 Final Drive Motor Gearbox For Excavator

Product Detail:

Travel Device is installed with Dual Displacement Axial Piston Motor and Travel Reduction Gearbox. Built-in Relief Valve, Anti-reverse Valve, Parking Brake and Dual speed switching device. Available for wide scope of ratios, high density, high efficiency, high reliability, small volume, smooth transmission, low noise as well as multi-level security protection and long serving life. Applicable to hydraulic track drive Final Drives.

Specification Of Product:

| Item | TM10 |

| Part Name | Travel Device |

| Input Flow(L/min) | 90 |

| Motor Displacement(ml/r) | 34/53 |

| Gear Ratio | 1/54.467 |

| Output Torque(N.m) | 13700 |

| Output Speed(r/min) | 48/31 |

| Frame Holes | 12 |

| Sprocket Holes | 12 |

| Application | 9-11 T |

| Application: | Motor, Machinery |

|---|---|

| Function: | Change Drive Direction, Speed Reduction |

| Layout: | Three-Ring |

| Hardness: | Soft Tooth Surface |

| Installation: | Torque Arm Type |

| Step: | Double-Step |

| Customization: |

Available

| Customized Request |

|---|

The Different Types of Gearboxes

There are many different types of gearboxes. Some brands have more than one type. In this article, we’ll discuss the planetary gearbox, the worm reduction gearbox, the shaft mounted gearbox, and the one speed gearbox. This article will also help you determine which type of gearbox is best for your vehicle. And don’t worry if you don’t know the terminology yet. We’ll explain each type in detail so that you know what you’re getting yourself into.

Planetary gearbox

Planetary gears have many advantages. The multiple gears in a planetary gearbox mesh simultaneously during operation. As such, they provide high efficiency and transmit high transmittable torque. These gears are widely used in various industries and are resistant to high shock loads and demanding conditions. CZPT is one of the companies that offer planetary gearboxes. Its products do not require special tools for assembly, and its scalable design minimizes safety stock.

Among the numerous benefits of planetary gearing is its compactness and lightweight. As such, it is suitable for wide applications with space and weight constraints. However, to truly appreciate its benefits, it is necessary to understand its mechanisms. Here are some of the most common details about planetary gearing:

The planetary gearbox has two mounted gears: an input shaft and an output shaft. Each gear has multiple teeth that are attached to a carrier and rotate with the input shaft. The carrier is connected to the output shaft. A planetary gear is mounted on both gears via a carrier. The carrier rotates in order to drive the planetary gear. The sun gear is often the input gear. The other gear is called the outer gear.

Planetary gearboxes are highly customizable. The size, mounting, and housing options vary, as do the reduction ratios and input speeds. Different types can be manufactured for different applications and include options such as electrical or mechanical preload. The final design of a planetary gearbox can be highly customized, based on the specifications of the application. By combining engineering excellence and ongoing innovation, planetary gearboxes provide years of trouble-free operation.

A planetary gearbox can be either an electric motor or a manual one. The latter has more features than the former, and can be used in applications where space is an issue. The primary features of a planetary gearbox include its backlash, torque, and ratio. Secondary features include noise, corrosion resistance, and construction. A planetary gearbox is a highly versatile gearbox that can drive anything from simple machinery to advanced electrical systems.

Worm reduction gearbox

The global worm reduction gearbox market report compiles key insights from the industry to help you improve your business strategy. This report will help you create a comprehensive business document that will enhance your company’s competitive edge. To obtain this report, visit our website now! Read our latest report to find out what you can expect from the global worm reduction gearbox market. Alternatively, request a sample copy for more details. Here is a sneak peek of the report:

Worm gears are made with different thread counts and are usually not matched with the CZPT standard. In general, a single thread worm should be used with a single thread worm. Worm gears have either right or left threads, and their thread count will be different as well. This type of gear is used to reduce the speed of a rotating shaft. The speed reduction ratio will be about 50 percent if the worms have the same thread count as the CZPT gears.

The standard gear set transfers power at the peak load point of a tooth, called the pitchline. The worm gear moves slowly against the wheel’s metal surface. The worm gear is also more complex than the standard gear because the worm is sliding rather than rolling. Worm gears are hard to lubricate. Moreover, the sliding contact between the gear and worm increases the complexity of the gear set. They can be a great solution for applications where noise is a significant factor.

The axial pitch and circular pitch of the worm are equal. The ratio of these two indices determines the speed of transmission. For a worm reduction gearbox to work, the axial pitch and the circular pitch must match. The pitch angle of a worm can either be left-handed or right-handed. The lead of a worm is the distance one thread travels in one revolution. The lead angle is the angle tangent to the thread helix of the cylinder’s pitch. When a worm mesh is reversed, the majority of the mesh will be on the receding arc.

Worm gears generate more heat than their counterparts, so it is important to choose a worm reduction gearbox carefully. You will want to choose the material and amount of lubricating oil carefully. Worm gears are generally made of tin bronze. The paired worms are hardened to HRC45-55. In general, they are durable, lasting up to ten years. But they will wear out – and they wear out – so you may want to consider some other factors.

Shaft-mounted gearbox

Shaft-mounted gearboxes are designed for a variety of mining and quarry applications. Their high reliability and low maintenance make them an excellent choice in these types of applications. Shaft-mounted gearboxes also feature an optional backstop device that prevents the unit from rotating in one direction. This makes them an excellent choice for applications where alignment accuracy is an issue. Here are some of the benefits of using a shaft-mounted gearbox:

Shaft-mounted gearboxes are typically constructed of aluminium, and come in sizes ranging from 050 to 125. They feature a variety of reduction ratios and ensure optimum efficiency in all operating conditions. New S series sizes, 140 and 150, extend the application range of shaft-mounted gearmotors. They are both backed by a two-year warranty. For even greater peace of mind, Shaft-mounted gearboxes are available with a range of warranty options.

The most common applications for a Shaft-mounted gearbox include traction-driven applications where a low-speed shaft is required for operation. They also are suitable for applications without a foundation, where the motor is mounted next to the reducer. To prevent the gear drive from rotating, a torque arm is attached between the motor and the shaft. Small-sized shaft-mounted gear drives are usually made without motor mount kits, which can make them an excellent choice for conveying light loads.

Another important feature of a Shaft-mounted gearbox is its mounting position. The reduced motion through the drive is redirected through the shaft, creating additional forces. These additional forces can affect the performance of the gearbox, causing vibrations and noise. Consequently, it is important to replace worn or damaged belts on a regular basis. Further, shaft-mounted gearboxes can be affected by problems with other components and amplify vibrations.

1 speed gearbox

CZPT Group Components produces one speed gearboxes. These transmissions are produced in the CZPT Group’s Kassel plant. They are compact and robust, and are designed for easy integration. The Bosch Rexroth GD1 one-speed gearbox is easy to install horizontally or vertically. The Plug and Drive system integrates the gearbox with the existing cooling system. There are many other benefits to this gearbox.

With an ID.3 electric drive motor, the maximum torque is delivered at 16,000 rpm. This single-speed transmission offers high power density and excellent noise-reduction, making it ideal for electric vehicles. The e-drive motor is extremely quiet and requires precision manufacturing. The e-drive motor also enables a wide range of driving conditions. It can reverse when needed, and reaches its maximum speed at 16,000.

The single-speed gearbox is a standard feature on most electric vehicles. Some electric vehicles, such as the Porsche Taycan, will be equipped with a two-speed gearbox. This gearbox offers more top speed and range, but it is more complex than a standard single-speed gearbox. CZPT doesn’t need to add complexity to its electric vehicles. After all, a 355 horsepower family wagon is not likely to need a dual-speed gearbox.

In addition to simplifying the transmission, the patent claims also address improvements in structural design. Fig. 5 shows a schematic representation of a transmission 50′, wherein gear sets Z1 and Z4 are exchanged between partial transmissions. This switch matrix also reflects the synchronized gears and lastshelf gears. Hydraulically betatigte Lamellenkupplungen (HBA) also form a last-shelf gear.

Another advantage of the patent claim is that it offers numerous functional freedoms, which is especially valuable in the design of an automobile. One of the patent claims identifies a tosatzlicher middle gear that allows a driver to switch between second and third gears, with a single gearbox. In a conventional one-speed transmission, the tosatzlicher middle gear is attached to the second and first part gearbox. The latter has a second and third gear.

editor by CX 2023-05-23

China high quality 12V 24V Worm Reduction Gearbox Nmrv Motovario Worm Gear Speed Reducer Motor Worm Gearboxes with Free Design Custom

Applicable Industries: Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company

Customized support: OEM

Gearing Arrangement: Worm

Output Torque: 40Nm

Input Speed: 3600Rpm

Output Speed: 40~250Rpm

Product Name: Nmrv Motovario Worm Gear Speed Reducer Motor Worm Gearboxes

Voltage: 12V 24V 36V 48V

Weight: 5 kg

Power: 200W~350W

Gear Material: Brass Gear

Brush Type: Carbon Brushed

Shaft Diameter: 20mm (Can Customized)

Packaging Details: 12v 24v dc electric golf cart trolley motor motor golf 24v 1. 4PCS/Carton. 2. Grossweight: 20KG/Carton.

item value Brand Name KSTONEMOTOR Model Number KS-90WZYJ08 (200W~350W) Certifications CE, Custom 12v 24v 36v 48v to 230vdc Brushless or Brushed Electric Dc Motor for Power Tools 50w 100w 200w 300w 400w 500w 800w 1000w ROHS, ISO9001 Continuous Current(A)25 A Efficiency IE 3 Torque100~400 kg.cm Voltage12V 24V 36V 48VRated Speed40~250rpmPower200~350 W Specification Related Products Company Profile HangZhou Dake Motor has always been an excellent DC Gear Motors manufacturer.The motors are widely used for Automotive, Home appliances, Personal care, Powertools, Industry, and Intelligent products which provide healthyand convenient ways in life. Dake has a large number of production equipment, test equipment, gear processing equipment imported from Japan and Switzerland. Buyer Comments Packing & Delivery 1. 4PCS/Carton2. Gross weight: 20 Kg/ Carton FAQ Q: Are you trading company or manufacturer?A: We are factory.Q: How to order?A: send us inquiry → receive our quotation → negotiate details → confirm the sample → sign contract/deposit → mass production → cargo ready → Drive shaft 3D7521101M use for VW PHAETON propshaft cardan shaft 3D7 521 101 M balance/delivery → further cooperationQ: How about Sample order?A: Sample is available for you. please contact us for details.Q: Which shipping way is available?A: DHL, FedEx, By Sea are available. The other shipping ways are also available, please contact us if you need ship by the other shipping way. Q: How long is the deliver, producing and shipping?A: Deliver time depends on the quantity you order. usually it takes 15-25 working days.Q: How to confirm the payment?A: We accept payment by T/T, PayPal, the other payment ways also could be accepted, Please contact us before you pay by the other payment ways. Also 50% deposit is available, the balance money should be paid before shipping.Q: What is your terms of payment?A: Payment=20000USD, 50% T/T in advance ,balance before shipment.If you have another question, please feel free to contact us.

Types of Vehicle Gearboxes

In a vehicle, there are many types of gearboxes available. There are planetary gearboxes, Coaxial helical gearboxes, and skew bevel helical gearboxes, among others. In this article, we’ll cover all of them and help you determine which type of gearbox would be right for your vehicle. Also, we’ll discuss how each differs from the others.

planetary gearbox

A planetary gearbox is composed of three main components: a sun gear, an input bevel gear, and an output shaft. A planetary gearbox can have different output torques and ratios. The basic model of a planetary gearbox is highly efficient and transmits 97% of the power input. There are several kinds of planetary gearboxes, depending on the type of operation. In general, there are three types: the simple, the intermediate, and the complex.

The price of a planetary gearbox can vary a lot, and it’s important to know what you’ll need. Different manufacturers produce different planetary gearboxes, so check with a manufacturer to see what they have available. Make sure to check the quality of the planetary gearbox before making a final purchase. In addition, be sure to compare the prices and the availability of a particular product. A quality planetary gearbox will provide years of trouble-free operation and will not break your bank.

Planetary gears feature an integer number of teeth. Each planet has teeth that must mesh with its ring or sun. The number of planets, ring, and tooth count of each gear determine whether the teeth mesh. Some planets have fewer teeth than others, so they mesh better than others. However, compound planets can be more flexible and achieve higher reduction ratios. If you’re looking for a planetary gearbox for your next project, consider getting in touch with a manufacturer who specializes in this technology.

When it comes to construction, a planetary gearbox is no exception. It’s extremely important to choose the right planetary gear for your application, because an imbalance in the planet gear can cause increased wear and failure. Moreover, the compact size of a planetary gear ensures maximum heat dissipation. However, a planetary gear box may require cooling in some applications. A planetary gearbox will make your life easier, and it will give you years of trouble-free operation.

Straight bevel helical gearbox

The Straight bevel helical gearbox has a number of advantages, but it has a relatively short manufacturing process. Its most popular application is in the automotive industry, where it is used in many types of vehicles. Other applications include heavy and light equipment and the aviation and marine industries. Below is a brief introduction to this gearbox type. Read on to learn about its benefits. This type of gearbox is one of the easiest to manufacture.

The spiral bevel gear has larger teeth than straight bevel gears, resulting in a smoother, quieter rotation. It can handle high-speed heavy loads with less vibration. Spiral bevel gears are classified by their tooth form and cutting method. Straight bevel gears are easier to design and manufacture, but spiral bevel gears are more expensive. Both designs are suitable for high-speed, heavy-load operations, and general manufacturing applications.

In addition to being easy to install, the modular bevel gears have many advantages. They have an exceptionally high degree of interchangeability and feature the highest standards of component integrity. They can also be tailored to meet your specific requirements. The advantages of this gearbox type include high precision, optimum performance, and low noise. And because they are modular, they can be produced in a variety of finishes. These include stainless steel, titanium, and bronze.

Straight bevel helical gearbox manufacturers are committed to a high degree of precision in their designs. The radii, torques, and tooth profiles of straight bevel gears are more precisely measured than those of cylindrical bevel gears. The same calculations are used for all traditional bevel gear generators. This ensures that your 5-axis milled bevel gear sets have the same calculations and layout.

Coaxial helical gearbox

The Coaxial helical gearbox is a highly efficient transmission system that is well suited for light-duty applications. Compared to spur-type gearboxes, the real pitch of a Coaxial helical gearbox is low at all helix angles. This is because the coaxial type has the same number of teeth and center gap as the spur gearbox. Coaxial helical gearboxes also have a smaller footprint and are compact.

Several nations have implemented lockdown regulations for Industrial Gearbox trade, threatening the global economy. Several factors have been implicated in COVID-19, including supply chain, market, and financial markets. Experts are monitoring the situation globally and project remunerative prospects for gearbox manufacturers after the crisis. This report depicts the latest scenario and offers a comprehensive analysis of COVID-19’s impact on the entire industry.

This Coaxial helical gearbox features a compact structure and high precision gear. Its three-stage design combines two-stage gears with a single-stage gear, forging high-quality alloy steel for high precision and durability. The gears are serially-designed for easy interchangeability. They are also available in high-frequency heat-treated steel. A Coaxial helical gearbox is the perfect solution for many applications.

Coaxial helical gearboxes have the added benefit of using cylindrical gears instead of shafts. They operate quietly, and have more surface area to interact with. Their fixed angles make them suitable for heavy-duty applications, like in conveyors, coolers, and grinders. Compared to other gearbox types, Helical gearboxes have higher power-carrying capacity. Listed below are the benefits of a Coaxial Helical Gearbox

Skew bevel helical gearbox

A Skew bevel helical gear box is a common type of industrial gearbox. These gearboxes are rigid and compact and can be used in a variety of applications. They are commonly used in heavy-duty applications such as grinding mills, conveyors, and coolers. They are used in many applications to provide rotary motions between non-parallel shafts. They also have the added benefit of high-efficiency in a variety of industries.

Skew bevel helical gear boxes are suitable for heavy loads and are monolithic in construction. This type of gearbox combines the benefits of bevel and helical gears for right-angle torque, which makes it a popular choice for heavy-duty applications. In addition to being a robust and reliable gearbox, these gearboxes are highly customizable and can meet almost any industrial need.

To maximize the efficiency of bevel gears, FE-based tooth contact analysis is used to develop a sophisticated geometry optimization algorithm. The software also allows users to define optimal flank topography by introducing application-specific weightings for specific load levels. With this data, a manufacturing simulation is conducted to determine the best variant. A robust variant combines the benefits of efficiency, load-carrying capacity, and low excitation behavior.

The helical gear can be angled at 90 degrees. This is similar to a spur gear but produces less noise. It can achieve a nine-to-one speed reduction with one stage. However, a helical gear requires a larger driver gear for higher reductions. This gearbox is suitable for speeds from 1:1 to three times. They are often used in the manufacture of motors and generators.

Extruder helical gearbox

An extruder helical gearbox is one of the most common industrial gears. It is compact in size and low-power consuming, making it ideal for heavy-duty applications. Extruder helical gearboxes are suitable for a variety of industrial applications, including cement, plastics, rubber, conveyors, and coolers. In addition to its use in plastics and rubber manufacturing, this gearbox is also useful in other low-power applications such as crushers, coolers, and conveyors.

CZPT SG series Extruder Helical Gearboxes are available in Single Screw and Twin Screw Variations. These gears feature a compact design, high power density, and long service life. Axial bearing housing and thrust bearings are mounted on the input shafts. Extruder helical gearboxes can be installed in various positions, including horizontal, vertical, and inclined.

Helicoidal gears are often produced in a modular manner. This design provides multiple benefits, including engineering and performance advantages, modular production, and the highest level of component integrity. A single helical gearbox can be assembled into a larger gearbox if needed, but modular production ensures consistent performance and economy. This modular design is also cost-effective. It is a versatile and reliable solution for a wide range of applications.

In addition to its efficiencies, Extruder helical gearboxes also have a low noise profile. They have no squeal sounds, and they are silent when running. They can transfer more power than conventional gearboxes. This type of gear has been used in the manufacturing of high-quality plastic products for years. They are often used for applications in automotive transmissions. Aside from being quiet, helical gears have higher contact levels and lower vibration.

in Puducherry India sales price shop near me near me shop factory supplier Speed Control AC Induction Geared Motor 140 Watt with Gear Reduction manufacturer best Cost Custom Cheap wholesaler

we provide one-end solution for the purchase of mechanical energy transmission merchandise in China. We supply OEM services. EPG was awarded with “popular merchandise of Zhejiang Province” and “well-known brand name of Zhejiang Province”. Item Description

velocity management ac induction EPTTed motor 140 watt with EPTT reduction Specs:

Notice : It is just the typical complex info for you reference, The specification such as voltage, pace, torque, shaft can EPT.

More Particulars:

Rated Voltage: 110V/220V/380V

No Load Pace: 10-600RPM

Load Torque: twenty-400kgf.cm

Reduction Ratio: three:one-two hundred:1

Output EPTT: 120W

EPTT Diameter: 104mm

EPTT Diameter: 104*104mm

EPTT Size: 187mm

EPTT Duration: 72mm

Shaft Type: 15h7

Related EPTT

Firm Profile

HangEPTT EPTT EPTT Co. Ltd is a company and exporter of numerous of motors with above ten years encounter.

Our product ranges incEPTT:

one) DC Brush motor: 6-130mm diameter, .01-1000W output EPTT

2) DC Spur Gear EPTT: 12-110mm diameter, .one-300W output EPTT

three) DC Planeary Equipment EPTT: 10-82mm diameter, .1-100W output EPTT

4) Brushless DC EPTT: 28-110mm, five-1500W output EPTT

5) Stepper EPTT: NEMA 08 to NEMA forty three, Can with EPTT and guide screw

6) Servo EPTT: 42mm to 130mm diameter, fifty-4000w

7) AC Equipment EPTT: 49 to 100mm diameter, 6-one hundred forty output EPTT

Manufacturing EPTT

Certifications

Client Visit and Reasonable

FAQ

Q: What’s your major products?

A:We at present generate Brushed Dc EPTTs, Brushed Dc EPTT EPTTs, Planetary Dc Equipment EPTTs, Brushless Dc EPTTs, Stepper motors and Ac EPTTs and so on. You can examine the specs for earlier mentioned motors on our web site and you can email us to advise required motors for each your specification way too.

Q:How to choose a suitable motor?

A:If you have motor photos or drawings to present us, or you have in depth specs like voltage, velocity, torque, motor measurement, operating method of the motor, necessary daily life time and sounds level and so on, you should do not be reluctant to allow us know, then we can advise ideal motor for each your ask for appropriately.

Q: Do you have EPT services for your stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd motors?

A:Yes, we can customise for every your ask for for the voltage, velocity, torque and shaft size/condition. If you require additional wires/cables soldered on the terminal or need to incorporate connectors, or capacitors or EMC we can make it as well.

Q:Do you have individual design provider for motors?

A:Sure, we would like to design motors independently for our customers, but it could want some mould charge and design cost.

Q:Can I have samples for screening very first?

A:Indeed, certainly you can. Following verified the required motor specs, we will estimate and provide a proforma bill for samples, after we get the payment, we will get a Pass from our account department to move forward samples appropriately.

Q:How do you make positive motor good quality?

A:We have our own inspection methods: for incoming supplies, we have signed sample and drawing to make sure experienced incoming materials for generation process, we have tour inspection in the method and final inspection to make sure experienced items ahead of transport.

Q:What is actually your direct time?

A:EPTTly sEPTTing, our regular stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd item will require twenty five-30days, a bit EPTTer for EPT products. But we are really fleXiHu (West Lake) Dis.ble on the direct time, it will is dependent on the distinct orders

Q:What is your payment time period?

A:For all our new buyers, we will need to have forty% deposite, 60% compensated just before cargo.

Q:When will you reply right after received my inquiries?

A:We will reaction in 24 hrs when get your inquires.

Q:How can I EPTT you to make confident my funds is risk-free?

A:We are licensed by the third social gathering SGS and we have exported to above eighty five international locations up to June.2017. You can check out our status with our existing buyers in your nation (if our clients do not head), or you can orEPTTvia alibaba to get trade assurance from alibaba to make positive your cash is secure.

Q:What is actually the bare minimum orEPTTquantity?

A:Our bare minimum orEPTTquantity relies upon on diverse motor designs, please e-mail us to check. Also, we normally do not acknowledge personal use motor orders.

Q:What’s your shipping and delivery strategy for motors?

A:For samples and offers less than 100kg, we normally propose convey delivery For hefty offers, we generally propose air shipping and delivery or sea shipping. But it all depends on our customers’ demands.

Q:What certifications do you have?

A:We at the moment have CE and ROSH certifications.

Q:Can you send me your price tag checklist?

A:Since we have hundreds of distinct merchandise, and price tag may differ per diverse specs, we are not able to offer a price listing. But we can quotation inside 24 hrs once acquired your inquirues to make positive you can get the price tag in time.

Q:Can I pay a visit to your business?

A:Of course, welcome to check out our company, but make sure you allow us know at lEPTT two weeks EPTT to support us make sure no other meetings for the duration of the day you check out us.

Many thanks!

Get in touch with Us

HangEPTT EPTT EPTT Co.,Ltd

Speak to Man or woman: Celia Chen

Any e mail or trademanager inquires will be replied inside of 24 hours.

Standard samples can be supply extremely swiftly(in 10 times)

Customized support for type of motor accoring to your need

Professional Tchnical support and Right after-sale provider

Sourcing motor areas like EPTTs, encoders, cables, connectors and so on