Product Description

PROFESSIONAL MANUFACTURE

— SINCE 1995

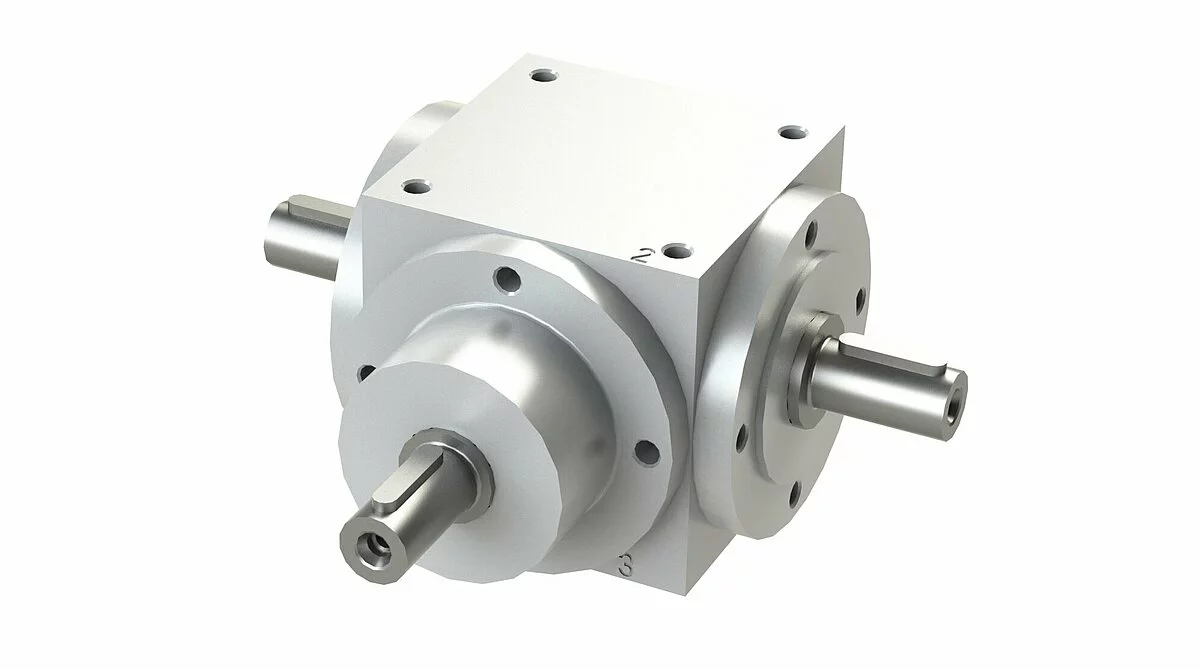

90 degree helical gear reduction box right angle spiral bevel gearbox with motor

Chinese electric motor speed reducer is widely used in mining machinery, chemical industry,steel metallurgy, light

industry,environmental protection, paper making, printing, lifting transport, food industry and so on.

Main Series Product: R series helical gear motor reducer, K series spiral bevel gear reducer, NGW, P series planetary gear reducer, H B series helical gearbox, Z (ZDY, ZLY, ZSY, and ZFY) serial hard tooth surface cylindrical gearbox reducer, D (DBY and DCY) serial hard tooth surface cone gear reducer, cycloidal speed reducer, etc. Meanwhile, map sample processing business can be undertaken.

Product Description

It realized serialization and modularization with compact structure and wide range of transmission ratio.

The transmission efficiency reach up to 96%.

The gear processed by Carburizing, Nitriding & Grinding.

High efficiency, superior performance with less energy consumption.

High precision gear, steady transmission, low noise, large load capacity, long service life.

Support various of installation method.

Product Parameters

|

Size |

K 47 57 |

K 67 |

K 77 |

K 87 |

K 97 |

K 107 |

K 127 |

K 157 |

K 167 187 |

|

Structure |

K KA KF KAF KAZ KAT KAB |

||||||||

|

Input power rating(kw) |

0.18-5.5 |

0.18-5.5 |

0.37-11 |

0.75-22 |

3-45 |

7.5-90 |

5.5-55KW |

11-160 |

18.5-200 |

|

Ratio |

6.57-145.14 |

7.14-144.79 |

7.24-192.18 |

7.19-197.37 |

8.95-176.05 |

8.68-146.07 |

12.65-150.41 |

5.00-163.31 |

17.27-180.78 |

|

Permissible torque N.m |

400/600 |

820 |

1550 |

2700 |

4300 |

8000 |

13000 |

1000 |

32000/50000 |

Model selection for washing machine Gear Box Transmission:

Closely using the ideal reduction ratio.

Reduction ratio = servo motor speed / reducer output shaft speed

Torque calculation: Torque calculation is very important for the life of reducer, and pay attention to whether the maximum torque value (TP) of acceleration exceeds the maximum load torque of the reducer.

The applicable power is usually the applicable power of the servo models on the market, the applicability of the reducer is very high, the working coefficient can be maintained above 1.2, but the choice can also be based on their own needs to decide. industrial helical gearbox. H PV series High quality Right Angle Unique speed reducer HB helical gearbox / gear box.

Detailed Photos

Chinese Speed Reducer/industrial helical gearbox is a mechanical transmission in many fields of the national economy. The product categories covered by the industry include all kinds of gear reducer, planetary gear reducer and worm reducer, as well as various special transmission devices such as speed increasing device, speed control Devices, including various types of flexible transmission devices, such as compound transmission. Products and services in the field of metallurgy, nonferrous metals, coal, building materials, ships, water conservancy, electricity, construction machinery and petrochemical industries.

In all fields of national economy and national defense industry, gearbox products have a wide range of applications. Food light industry, electric machinery, construction machinery, metallurgy machinery, cement machinery, environmental protection machinery, electronic appliances, road construction machinery, water conservancy machinery, chemical machinery, mining machinery, conveyor machinery, building materials machinery, rubber machinery, petroleum machinery and other industries have strong demand of Reducer products.

Packaging & Shipping

Application

| Driven machines | |||

| Waste water treatment | Thickeners,filter presses,flocculation apparata,aerators,raking equipment,combined longitudinal and rotary rakes,pre-thickeners,screw pumps,water turbines,centrifugal pumps | Dredgers | Bucket conveyors, dumping devices, carterpillar travelling gears, bucket wheel excavators as pick up, bucket wheel excavator for primitive material, cutter head, traversing gears |

| Chemical industry | Plate bending machines, extruders, dough mills, rubbers calenders, cooling drums, mixers for uniform media, agitators for media with uniform density, toasters, centrifuges | Metal working mills | plate tilters, ingot pushers, winding machines, cooling bed transfer frames, roller straigheners, table continuous intermittent, roller tables reversing tube mills, shears continuous, casting drivers, reversing CZPT mills |

| Metal working mills | Reversing slabbing mills. reversing wire mills, reversing sheet mills, reversing plate mill, roll adjustment drives | Conveyors | Bucket conveyors, hauling winches, hoists, belt conveyors, good lifts, passenger lifts, apron conveyors, escalators, rail travlling gears |

| Frequency converters | Reciprocating compressors | ||

| Cranes | Slewing gears, luffing gears, travelling gears, hoisting gear, derricking jib cranes | Cooling towers | Cooling tower fans, blowers axial and radial |

| Cane sugar production | Cane knives, cane mills | Beet sugar production | Beet cossettes macerators, extraction plants, mechanical refrigerators, juice boilers, sugar beet washing machines, sugar beet cutter |

| Paper machines | Pulper drives | Cableways | Material ropeways, continuous ropeway |

| Cement industry | Concrete mixer, breaker, rotary kilns, tube mills, separators, roll crushers | ||

Company Profile

Established in 1995 , HangZhou Boji Machinery is a professional manufacturer and exporter that is concerned with the design, development and production of Gearbox Speed Reducer. We are located in HangZhou of ZheJiang Province, with convenient transportation access. With our own brand “TianQi”, all of our products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world.

Our company possesses complete machining center, lathe, gear shaping machine, gear milling machine, gear grinding machine and assembling lines. Our well-equipped facilities and excellent quality control throughout all stages of production enables us to guarantee total customer satisfaction.

Besides, In 2005,we attained ISO9001 certification. As a result of our high quality products and outstanding customer service, we have gained a global sales network CZPT South America, Saudi Arabia, Vietnam, Pakistan, Philippines, South Africa and other countries and regions.

With rich export experience, high quality products, competitive prices, good service and in-time delivery, we certain that we can meet all of your requirement and exceed your expectations. Our feature is bright with new cooperative relationships with companies from all over the world. We look CZPT to speaking with you to future discuss how we can be of service to you.

FAQ

1. Who are we?

We are the Factory, with over 25 years of production experience, based in ZheJiang , China, start from 1995,sell to Domestic Market(50.00%),Mid East(10.00%),Southeast Asia(10.00%),Western Europe(5.00%),South America(5.00%),Eastern Europe(5.00%),Eastern Asia(5.00%),North America(3.00%),Africa(2.00%),Southern Europe(2.00%),South Asia(2.00%),Central America(1.00%).

2. Can you customize according to our requirements?

Yes, we can design nonstandard products according to customer’s drawing and sample.

3.What can you buy from us?

speed reducer,gearbox,gear motor,pump,crusher

4. Why should you buy from us not from other suppliers?

Founded in 1995, with over 20 years of production experience and credibility. With professional engineer team, advanced technology production and skilled workers.Specialized in the production of reducer. Map sample processing business can be undertaken.

5. What services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,DDP,DDU,Express Delivery;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,Credit Card,PayPal,Western Union,Cash;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Hindi,Italian

|

Shipping Cost:

Estimated freight per unit. |

To be negotiated |

|---|

| Application: | Motor, Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Samples: |

US$ 480/Piece

1 Piece(Min.Order) | Order Sample 90 degree right angle spiral bevel gearbox

|

|---|

| Customization: |

Available

| Customized Request |

|---|

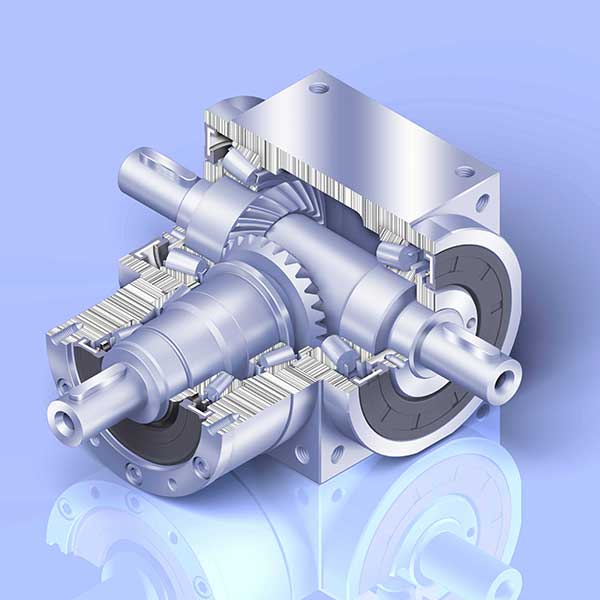

Differences Between Spiral Bevel Gearboxes and Other Gearbox Types

Spiral bevel gearboxes differ from other gearbox types in several key aspects:

- Gear Tooth Design: Spiral bevel gearboxes use spiral bevel gears with angled teeth, which allow for smoother meshing and reduced impact compared to straight bevel gears. In contrast, other gearbox types might use spur gears, helical gears, or worm gears, each with distinct tooth profiles.

- Shaft Arrangement: Spiral bevel gearboxes have intersecting input and output shafts set at right angles. This enables power transmission between shafts that are not aligned. Other gearbox types, such as parallel shaft gearboxes, have shafts that are parallel to each other.

- Direction Changes: Spiral bevel gearboxes are well-suited for applications requiring direction changes between input and output shafts due to their perpendicular shaft arrangement. Worm gearboxes, on the other hand, are commonly used for large speed reductions and right-angle drives.

- High Torque Transmission: Spiral bevel gearboxes offer high torque transmission capabilities due to the larger contact area of their gear teeth. Planetary gearboxes, while also capable of handling high torque, have a different gear arrangement involving sun, planet, and ring gears.

- Noise and Vibration: Spiral bevel gearboxes tend to produce less noise and vibration compared to straight bevel gearboxes, thanks to their spiral tooth design. Helical gearboxes, which also use angled teeth, offer similar advantages in terms of noise reduction.

- Applications: Spiral bevel gearboxes are commonly used in automotive differentials, aerospace systems, and heavy machinery. Other gearbox types find applications in various industries based on their unique characteristics and advantages.

Overall, the distinctive features of spiral bevel gearboxes set them apart from other gearbox types, making them suitable for specific applications where direction changes, torque transmission, and smooth operation are critical factors.

Contribution of Spiral Bevel Gearboxes to Mechanical System Efficiency

Spiral bevel gearboxes play a crucial role in enhancing the overall efficiency of mechanical systems by:

- Power Transmission: Spiral bevel gearboxes efficiently transmit power between non-parallel and intersecting shafts, allowing mechanical systems to transfer rotational motion with minimal energy loss.

- High Efficiency: The unique tooth geometry of spiral bevel gears ensures smooth and continuous contact between gear teeth, resulting in higher mechanical efficiency compared to other types of gearboxes.

- Optimized Torque Distribution: Spiral bevel gearboxes distribute torque uniformly across the gear teeth, minimizing the concentration of stress and wear on specific teeth. This leads to improved load-sharing capabilities and reduced mechanical losses.

- Reduced Friction and Heat Generation: The rolling action of spiral bevel gears reduces sliding friction, minimizing heat generation and energy losses that often occur in sliding contact gear systems.

- Noise and Vibration Reduction: The meshing of spiral bevel gears generates less noise and vibration compared to other gear types, resulting in smoother and quieter operation.

- Compact Design: Spiral bevel gearboxes can be designed with a compact form factor, allowing for efficient utilization of space in various mechanical systems.

- Customizable Ratios: Gear ratios in spiral bevel gearboxes can be tailored to specific application requirements, ensuring optimal speed and torque matching.

- Reliable Power Transfer: Spiral bevel gears’ robust design and accurate tooth meshing contribute to reliable power transfer even under varying loads and operating conditions.

- Long Service Life: Properly designed and maintained spiral bevel gearboxes exhibit high durability and wear resistance, contributing to extended service life.

By effectively transmitting power, optimizing torque distribution, reducing friction, and providing smooth and reliable operation, spiral bevel gearboxes significantly enhance the overall efficiency of mechanical systems in various industries.

editor by CX 2023-09-04

China 130 140 ratio variable speed bevel gear 90 degree bevel gearbox reduction for sale Conveyor differential gearbox

Applicable Industries: Producing Plant, Food & Beverage Manufacturing facility, Design works , Strength & Mining, pace bevel equipment 90 degree bevel gearbox reduction

Gearing Arrangement: Cycloidal

Output Torque: 375~519520Nm(customized)

Enter Velocity: 6 P series planetary reducer, H B series gearbox, Z (ZDY, ZLY, ZSY, and ZFY) serial tough tooth surface cylindrical gear reducer, D (DBY and DCY) serial tough tooth floor cone equipment reducer, cycloid reducer, etc. In the meantime, map sample processing company can be undertaken.

Specification H B Collection Gearbox Reducer:

(remember to make contact with us for more varieties & model)

| Sort | n r/min | TransmissionRatio (i) | Variety | n r/min | TransmissionRatio (i) | Variety | n r/min | TransmissionRatio (i) | Variety | n r/min | TransmissionRatio (i) |

| H1SH | 750 | 1.twenty five-two | H2 B2 | 750 | five-9 | H3 B3 | 750 | twelve.5-112 | H4 B4 | 750 | 80-450 |

| 2.24-5.six | ten-28 | a thousand | twelve.5-112 | 1000 | 80-450 | ||||||

| 1000 | 1.twenty five-two | 1000 | five-nine | 1500 | twelve.5-31.5 | 1500 | 80-112 | ||||

| 2.24-5.6 | 10-28 | 35.5-fifty six | 125-450 | ||||||||

| 1500 | 1.twenty five-two | 1500 | 5-6.3 | sixty three-112 | |||||||

| four-5.six | 7-nine | ||||||||||

| 10-sixteen | |||||||||||

| 18-28 | |||||||||||

Product choice for Gear Box Transmission:

Carefully making use of the best reduction ratio.

Reduction ratio = servo motor speed / reducer output shaft velocity

Torque calculation: Torque calculation is very important for the life of reducer, and shell out consideration to whether or not the greatest torque worth (TP) of acceleration exceeds the highest load torque of the reducer.

The applicable electricity is usually the applicable energy of the servo models on the market, the applicability of the reducer is really high, the doing work coefficient can be maintained over 1.2, but the selection can also be based on their own wants to make a decision.H B series normal industrial equipment box reducer.Industrial Appropriate Angle Transmission Gearbox value.Gearbox Producer helical gear style gearbox with average price tag.HB Bevel helical gearbox for h2o treatment.Chinese Gearbox Company H B Collection Industrial Gear Box Reducer.Higher Torque H B Helical gearbox for hauling winches..H B Helical Substantial rpm Reduction Gearbox price for conveyors 1:40 ratio.High precision H B collection industrial large duty equipment gearbox pace reducer.right angle spiral bevel gearbox charges for lifting cranes.proper angle 5: 1 ratio gearbox reduction gearbox prices for extruders and mixers.drill velocity reducer gearbox speed increaser for Dredging Equipments.ninety diploma transmission gearbox for amusement park equipment stage gear.1:thirty 1:forty ratio variable velocity bevel equipment 90 diploma bevel gearbox reduction for sale Conveyor.

Business DataStarted in 1995, HangZhou Boji Electricity equipment Co.,Ltd has 22 many years of reducer manufacturing expertise and credibility. The business has professional engineer staff, innovative technologies production and experienced employees, with positioned in HangZhou of ZheJiang province which has solid industrial foundation and produced transportation.

Attribute:

Chinese Velocity Reducer is a mechanical transmission in several fields of the countrywide economic system. The product classes covered by the industry include all types of equipment reducer, planetary equipment reducer and worm reducer, as properly as numerous special transmission devices these kinds of as pace rising unit, velocity manage Units, which includes a variety of sorts of adaptable transmission products, this kind of as compound transmission. Products and services in the area of metallurgy, nonferrous metals, coal, constructing materials, ships, drinking water conservancy, electricity, building equipment and petrochemical industries.a hundred: 1 ratio gearbox.

In all fields of countrywide financial system and national protection sector, gearbox items have a broad selection of purposes. Foods light industry, electrical equipment, design machinery, metallurgy equipment, cement machinery, Prickly thorn necklace ins area of interest style men ladies indifferent trousers hip hop punk collar thick bracelet trousers chain environmental protection equipment, digital appliances, highway building machinery, drinking water conservancy equipment, chemical equipment, mining machinery, conveyor machinery, developing supplies equipment, rubber equipment, petroleum machinery and other industries have strong demand from customers of Reducer merchandise.Industrial Right Angle Transmission Gearbox value.Gearbox Producer helical gear design gearbox with average price tag.HB Bevel helical gearbox for h2o treatment.Chinese Gearbox Producer H B Collection Industrial Gear Box Reducer.Substantial Torque H B Helical gearbox for hauling winches.H B Sequence Helical gearbox for bucket elevators.washing equipment H B Helical equipment box cost for hauling winches and conveyors.H B Helical Large rpm Reduction Gearbox cost for conveyors 1:40 ratio.3: 1 ratio gearbox.1:thirty ratio gearbox.Higher precision H B sequence industrial large obligation equipment gearbox pace reducer.appropriate angle spiral bevel gearbox prices for lifting cranes.correct angle 5: 1 ratio gearbox reduction gearbox prices for extruders and mixers.drill speed reducer gearbox velocity increaser for Dredging Equipments.ninety degree transmission gearbox for amusement park equipment stage tools.Reduction ratio B sequence Cycloid Speed Reducer Gearbox.1:thirty 1:forty ratio variable pace bevel equipment ninety diploma bevel gearbox reduction for sale Conveyor.

Packaging & Delivery

A:We are the professional Manufacturing facility with 22 a long time of experience.

2.Q:Can you customize according to our requirements?

A:Of course, we can design nonstandard goods according to customer’s drawing and sample.

three.Q:How long is the shipping date?

A:ten-twenty functioning times.

four.Q:Exactly where is your factory?

A:We are in HangZhou of ZheJiang Province, you can get below by higher velocity practice or fly to HangZhou.

Welcome to visit us!

What Is a Gearbox?

There are several factors to consider when choosing a gearbox. Backlash, for example, is a consideration, as it is the angle at which the output shaft can rotate without the input shaft moving. While this isn’t necessary in applications without load reversals, it is important for precision applications involving load reversals. Examples of these applications include automation and robotics. If backlash is a concern, you may want to look at other factors, such as the number of teeth in each gear.

Function of a gearbox

A gearbox is a mechanical unit that consists of a chain or set of gears. The gears are mounted on a shaft and are supported by rolling element bearings. These devices alter the speed or torque of the machine they are used in. Gearboxes can be used for a wide variety of applications. Here are some examples of how gearboxes function. Read on to discover more about the gears that make up a gearbox.

Regardless of the type of transmission, most gearboxes are equipped with a secondary gear and a primary one. While the gear ratios are the same for both the primary and secondary transmission, the gearboxes may differ in size and efficiency. High-performance racing cars typically employ a gearbox with two green and one blue gear. Gearboxes are often mounted in the front or rear of the engine.

The primary function of a gearbox is to transfer torque from one shaft to another. The ratio of the driving gear’s teeth to the receiving member determines how much torque is transmitted. A large gear ratio will cause the main shaft to revolve at a slower speed and have a high torque compared to its counter shaft. Conversely, a low gear ratio will allow the vehicle to turn at a lower speed and produce a lower torque.

A conventional gearbox has input and output gears. The countershaft is connected to a universal shaft. The input and output gears are arranged to match the speed and torque of each other. The gear ratio determines how fast a car can go and how much torque it can generate. Most conventional transmissions use four gear ratios, with one reverse gear. Some have two shafts and three inputs. However, if the gear ratios are high, the engine will experience a loss of torque.

In the study of gearbox performance, a large amount of data has been collected. A highly ambitious segmentation process has yielded nearly 20,000 feature vectors. These results are the most detailed and comprehensive of all the available data. This research has a dual curse – the first is the large volume of data collected for the purpose of characterization, while the second is the high dimensionality. The latter is a complication that arises when the experimental gearbox is not designed to perform well.

Bzvacklash

The main function of a gearhead is to multiply a moment of force and create a mechanical advantage. However, backlash can cause a variety of issues for the system, including impaired positioning accuracy and lowered overall performance. A zero backlash gearbox can eliminate motion losses caused by backlash and improve overall system performance. Here are some common problems associated with backlash in gearheads and how to fix them. After you understand how to fix gearbox backlash, you’ll be able to design a machine that meets your requirements.

To reduce gearbox backlash, many designers try to decrease the center distance of the gears. This eliminates space for lubrication and promotes excessive tooth mesh, which leads to premature mesh failure. To minimize gearbox backlash, a gear manufacturer may separate the two parts of the gear and adjust the mesh center distance between them. To do this, rotate one gear with respect to the fixed gear, while adjusting the other gear’s effective tooth thickness.

Several manufacturing processes may introduce errors, and reducing tooth thickness will minimize this error. Gears with bevel teeth are a prime example of this. This type of gear features a small number of teeth in comparison to its mating gear. In addition to reducing tooth thickness, bevel gears also reduce backlash. While bevel gears have fewer teeth than their mating gear, all of their backlash allowance is applied to the larger gear.

A gear’s backlash can affect the efficiency of a gearbox. In an ideal gear, the backlash is zero. But if there is too much, backlash can cause damage to the gears and cause it to malfunction. Therefore, the goal of gearbox backlash is to minimize this problem. However, this may require the use of a micrometer. To determine how much gearbox backlash you need, you can use a dial gauge or feeler gauge.

If you’ve been looking for a way to reduce backlash, a gearbox’s backlash may be the answer. However, backlash is not a revolt against the manufacturer. It is an error in motion that occurs naturally in gear systems that change direction. If it is left unaccounted for, it can lead to major gear degradation and even compromise the entire system. In this article, we’ll explain how backlash affects gears and how it affects the performance of a gearbox.

Design

The design of gearboxes consists of a variety of factors, including the type of material used, power requirements, speed and reduction ratio, and the application for which the unit is intended. The process of designing a gearbox usually begins with a description of the machine or gearbox and its intended use. Other key parameters to consider during gearbox design include the size and weight of the gear, its overall gear ratio and number of reductions, as well as the lubrication methods used.

During the design process, the customer and supplier will participate in various design reviews. These include concept or initial design review, manufacturing design validation, critical design review, and final design review. The customer may also initiate the process by initiating a DFMEA. After receiving the initial design approval, the design will go through several iterations before the finalized design is frozen. In some cases, the customer will require a DFMEA of the gearbox.

The speed increaser gearboxes also require special design considerations. These gearboxes typically operate at high speeds, causing problems with gear dynamics. Furthermore, the high speeds of the unit increase frictional and drag forces. A proper design of this component should minimize the effect of these forces. To solve these problems, a gearbox should incorporate a brake system. In some cases, an external force may also increase frictional forces.

Various types of gear arrangements are used in gearboxes. The design of the teeth of the gears plays a significant role in defining the type of gear arrangement in the gearbox. Spur gear is an example of a gear arrangement, which has teeth that run parallel to the axis of rotation. These gears offer high gear ratios and are often used in multiple stages. So, it is possible to create a gearbox that meets the needs of your application.

The design of gearboxes is the most complex process in the engineering process. These complex devices are made of multiple types of gears and are mounted on shafts. They are supported by rolling element bearings and are used for a variety of applications. In general, a gearbox is used to reduce speed and torque and change direction. Gearboxes are commonly used in motor vehicles, but can also be found in pedal bicycles and fixed machines.

Manufacturers

There are several major segments in the gearbox market, including industrial, mining, and automotive. Gearbox manufacturers are required to understand the application and user industries to design a gearbox that meets their specific requirements. Basic knowledge of metallurgy is necessary. Multinational companies also provide gearbox solutions for the power generation industry, shipping industry, and automotive industries. To make their products more competitive, they need to focus on product innovation, geographical expansion, and customer retention.

The CZPT Group started as a small company in 1976. Since then, it has become a global reference in mechanical transmissions. Its production range includes gears, reduction gearboxes, and geared motors. The company was the first in Italy to achieve ISO certification, and it continues to grow into one of the world’s leading manufacturers of production gearboxes. As the industry evolves, CZPT focuses on research and development to create better products.

The agriculture industry uses gearboxes to implement a variety of processes. They are used in tractors, pumps, and agricultural machinery. The automotive industry uses gears in automobiles, but they are also found in mining and tea processing machinery. Industrial gearboxes also play an important role in feed and speed drives. The gearbox industry has a diverse portfolio of manufacturers and suppliers. Here are some examples of gearboxes:

Gearboxes are complex pieces of equipment. They must be used properly to optimize efficiency and extend their lifespan. Manufacturers employ advanced technology and strict quality control processes to ensure their products meet the highest standards. In addition to manufacturing precision and reliability, gearbox manufacturers ensure that their products are safe for use in the production of industrial machinery. They are also used in office machines and medical equipment. However, the automotive gearbox market is becoming increasingly competitive.

editor by czh2023-02-13

in Busto Arsizio Italy sales price shop near me near me shop factory supplier Best Small 90 Degree Gears, Right Angle Spiral Bevel Gearbox Price manufacturer best Cost Custom Cheap wholesaler

Hangzhou EPG Co.,Ltd. , was launched in November, 1997. With its five wholly owned subsidiaries. Possessing amassed precious encounter in cooperating with international buyers, “We are often serving our buyers with our very best products.”

We are expert very best small ninety degree EPTTs, rigEPTT angle spiral EPTTl EPTT producers and suppliers from EPTT. All tiny 90 degree EPTTs, rigEPTT angle spiral EPTTl EPTT will be tested with inspection stories prior to items shipment.

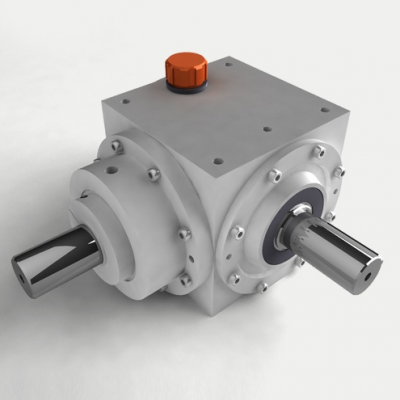

JTP Sequence Cubic EPTTl EPTT

EPTT JTP series cubic EPTTl EPTT is also known as cubic rigEPTT angle miter EPTT, cubic ninety diploma EPTTl EPTT, cubic miter EPTTl EPTT box, or cubic spiral EPTTl EPTT EPTTs. JTP collection cubic EPTTl EPTT is a right-angle shaft variety EPTT box of spiral EPTTl EPTTs for EPTT purposes with large EPTT capacity, substantial efficiency and higher efficiency. 1:one, 1.five:1, two:1, three:1, four:one and 5:one EPTT ratios as stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd. 2 way(one enter 1 output), 3 way(1 enter two output, or two enter one output), 4 way(two input two output) EPTT shafts as stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd. Reliable shaft as stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd, personalize hollow shaft or motor flange to bolt an IEC motor flange. MaXiHu (West Lake) Dis.mum torque 1299N.m. MaXiHu (West Lake) Dis.mum enter and output velocity 1450RPM. There are 8 versions: JTP65 mini cubic EPTTl EPTT, JTP90 cubic EPTTl EPTT, JTP110 cubic EPTTl EPTT, JTP140 cubic EPTTl EPTT, JTP170 cubic EPTTl EPTT, JTP210 cubic EPTTl EPTT, JTP240 cubic EPTTl EPTT and JTP280 cubic EPTTl EPTT.

| JTP65 Mini Cubic EPTTl EPTT 1. EPTTl EPTT ratio 1:1 two. reliable EPTT shafts diameter12mm three. sound enter and output shaft shafts four. 2 way, 3 way, four way EPTT 5. enter EPTT maXiHu (West Lake) Dis.mum 1.8Kw six. EPTT torque maXiHu (West Lake) Dis.mum thirteen.5Nm seven. maXiHu (West Lake) Dis.mum input 1500rpm |

JTP90 Cubic EPTTl EPTT 1. EPTT ratios one:1, one.five:1, two:one, three:1, four:one five:1 2. cubic, 6 mount positions, EPTT mount 3. reliable shaft, hollow shaft, motor flange 4. 2 way, three way, four way EPTT 5. enter EPTT maXiHu (West Lake) Dis.mum 6Kw six. EPTT torque maXiHu (West Lake) Dis.mum forty three.3Nm seven. maXiHu (West Lake) Dis.mum input 1500rpm |

JTP110 Cubic EPTTl EPTT one. EPTT ratios one:1, one.5:1, 2:1, three:1, four:1 5:one 2. cubic, six mount positions, EPTT mount 3. sound shaft, hollow shaft, motor flange 4. 2 way, three way, 4 way EPTT five. enter EPTT maXiHu (West Lake) Dis.mum 11Kw 6. EPTT torque maXiHu (West Lake) Dis.mum 78.3Nm 7. maXiHu (West Lake) Dis.mum enter 1500rpm |

| JTP140 Cubic EPTTl EPTT 1. EPTT ratios 1:1, 1.five:one, two:one, 3:one, four:1 five:1 two. cubic, 6 mount positions, EPTT mount 3. reliable shaft, hollow shaft, motor flange four. 2 way, 3 way, four way EPTT five. enter EPTT maXiHu (West Lake) Dis.mum 23. 9Kw 6. EPTT torque maXiHu (West Lake) Dis.mum 170Nm seven. maXiHu (West Lake) Dis.mum input 1500rpm |

JTP170 Cubic EPTTl EPTT 1. EPTT ratios one:one, 1.5:1, 2:one, three:one, four:1 five:1 two. cubic, 6 mount positions, EPTT mount 3. solid shaft, hollow shaft, motor flange 4. two way, 3 way, 4 way EPTT five. enter EPTT maXiHu (West Lake) Dis.mum 39.2Kw six. EPTT torque maXiHu (West Lake) Dis.mum 290Nm seven. maXiHu (West Lake) Dis.mum enter 1500rpm |

JTP210 Cubic EPTTl EPTT one. EPTT ratios 1:1, one.5:1, two:one, three:1, 4:1 5:1 two. cubic, six mount positions, EPTT mount three. reliable shaft, hollow shaft, motor flange four. 2 way, 3 way, four way EPTT 5. enter EPTT maXiHu (West Lake) Dis.mum 67.5Kw 6. EPTT torque maXiHu (West Lake) Dis.mum 520Nm seven. maXiHu (West Lake) Dis.mum enter 1500rpm |

| JTP240 Cubic EPTTl EPTT 1. EPTT ratios 1:one, one.five:one, 2:1, 3:1, four:1 five:1 two. cubic, 6 mount positions, EPTT mount 3. sound shaft, hollow shaft, motor flange four. two way, 3 way, four way EPTT 5. input EPTT maXiHu (West Lake) Dis.mum ninety.5Kw 6. EPTT torque maXiHu (West Lake) Dis.mum 694Nm 7. maXiHu (West Lake) Dis.mum input 1500rpm |

JTP280 Cubic EPTTl EPTT one. EPTT ratios one:1, one.five:one, 2:1, three:1, 4:1 five:1 two. cubic, 6 mount positions, EPTT mount 3. solid shaft, hollow shaft, motor flange four. 2 way, 3 way, four way EPTT 5. input EPTT maXiHu (West Lake) Dis.mum 156Kw 6. EPTT torque maXiHu (West Lake) Dis.mum 1199Nm seven. maXiHu (West Lake) Dis.mum enter 1500rpm |

|

JT Series Spiral EPTTl EPTT

EPTT JT collection spiral EPTTl EPTT is also identified as miter EPTTl EPTT box, spiral EPTTl EPTT EPTTs, rigEPTT angle miter EPTT, or ninety degree EPTTl EPTT. JT sequence spiral EPTTl EPTT is a right-angle shaft sort EPTT box of spiral EPTTl EPTTs for EPTT apps with higher EPTT potential, large performance and substantial efficiency. 1:1, one.five:1, 2:1, 2.five:1, 3:1, 4:one and five:1 EPTT ratios as stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd. 2 way(1 input one particular output), 3 way(one enter two output, or two enter 1 output), 4 way(two input two output) EPTT shafts as stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd. Solid shaft as stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd, personalize hollow shaft or motor flange to bolt an IEC motor flange. MaXiHu (West Lake) Dis.mum torque 5713N.m. MaXiHu (West Lake) Dis.mum input and output pace 1450RPM. There are 10 models: JT15 spiral EPTTl EPTT, JT19 spiral EPTTl EPTT, JT25 spiral EPTTl EPTT, JT32 spiral EPTTl EPTT, JT40 spiral EPTTl EPTT, JT45 spiral EPTTl EPTT, JT50 spiral EPTTl EPTT, JT60 spiral EPTTl EPTT, JT72 spiral EPTTl EPTT, JT85 spiral EPTTl EPTT.

| JT15 Spiral EPTTl EPTT one. spiral teeth miter EPTTl EPTTs 2. 90 degree rigEPTT angle EPTTs 3. EPTTl EPTT ratios 1:1, two:one 4. two way, 3 way, 4 way EPTTes 5. input EPTT maXiHu (West Lake) Dis.mum 1.79Kw six. EPTT torque maXiHu (West Lake) Dis.mum 28Nm 7. EPTT shaft diameter 15mm |

JT19 Spiral EPTTl EPTT 1. spiral tooth miter EPTTl EPTTs 2. ninety degree rigEPTT angle EPTTs 3. EPTTl EPTT ratios 1:1, 2:one 4. two way, 3 way, 4 way EPTTes 5. enter EPTT maXiHu (West Lake) Dis.mum four.94Kw 6. EPTT torque maXiHu (West Lake) Dis.mum forty eight.5Nm 7. EPTT shaft diameter 19mm |

JT25 Spiral EPTTl EPTT one. spiral teeth miter EPTTl EPTTs two. ninety diploma rigEPTT angle EPTTs 3. ratios one:1, 1.five:1, 2:one, 2.5:1, 3:1, 4:1, five:1 4. 2 way, 3 way, four way EPTTes 5. enter EPTT maXiHu (West Lake) Dis.mum fourteen.9Kw six. EPTT torque maXiHu (West Lake) Dis.mum 132Nm seven. EPTT shaft diameter 25mm |

| JT32 Spiral EPTTl EPTT 1. spiral teeth miter EPTTl EPTTs two. ninety diploma rigEPTT angle EPTTs 3. ratios 1:1, 1.5:1, two:1, two.five:one, 3:1, 4:one, 5:1 4. 2 way, three way, 4 way EPTTes five. input EPTT maXiHu (West Lake) Dis.mum 22Kw six. EPTT torque maXiHu (West Lake) Dis.mum 214Nm 7. EPTT shaft diameter 32mm |

JT40 Spiral EPTTl EPTT one. spiral teeth miter EPTTl EPTTs 2. 90 diploma rigEPTT angle EPTTs three. ratios one:one, one.five:one, 2:one, two.5:1, 3:1, 4:one, five:1 4. 2 way, three way, 4 way EPTTes 5. enter EPTT maXiHu (West Lake) Dis.mum forty five.6Kw six. EPTT torque maXiHu (West Lake) Dis.mum 361Nm 7. EPTT shaft diameter 40mm |

JT45 Spiral EPTTl EPTT 1. spiral teeth miter EPTTl EPTTs 2. ninety degree rigEPTT angle EPTTs three. ratios one:1, 1.5:one, two:one, 2.5:1, three:1, four:1, five:1 four. 2 way, three way, four way EPTTes five. enter EPTT maXiHu (West Lake) Dis.mum sixty five. 3Kw six. EPTT torque maXiHu (West Lake) Dis.mum 561Nm seven. EPTT shaft diameter 45mm |

| JT50 Spiral EPTTl EPTT 1. spiral enamel miter EPTTl EPTTs two. ninety diploma rigEPTT angle EPTTs three. ratios 1:1, one.five:1, 2:one, 2.five:one, 3:one, four:one, five:1 four. two way, 3 way, 4 way EPTTes five. input EPTT maXiHu (West Lake) Dis.mum 96Kw 6. EPTT torque maXiHu (West Lake) Dis.mum 919Nm 7. EPTT shaft diameter 50mm |

JT60 Spiral EPTTl EPTT one. spiral tooth miter EPTTl EPTTs two. ninety diploma rigEPTT angle EPTTs three. ratios 1:1, two:one, three:1, 4:1, five:one four. 2 way, three way, four way EPTTes 5. input EPTT maXiHu (West Lake) Dis.mum 163Kw 6. EPTT torque maXiHu (West Lake) Dis.mum 1940Nm seven. EPTT shaft diameter 60mm |

JT72 Spiral EPTTl EPTT 1. spiral tooth miter EPTTl EPTTs 2. ninety diploma rigEPTT angle EPTTs three. ratios one:1, 2:one, three:1, four:one, 5:1 four. two way, 3 way, 4 way EPTTes 5. input EPTT maXiHu (West Lake) Dis.mum 234Kw 6. EPTT torque maXiHu (West Lake) Dis.mum 3205Nm seven. EPTT shaft diameter 72mm |

| JT85 Spiral EPTTl EPTT one. spiral teeth miter EPTTl EPTTs 2. 90 degree rigEPTT angle EPTTs 3. ratios one:1, 2:1, three:one, 4:one, five:one 4. two way, 3 way, 4 way EPTTes 5. enter EPTT maXiHu (West Lake) Dis.mum 335Kw 6. EPTT torque maXiHu (West Lake) Dis.mum 5713Nm 7. EPTT shaft diameter 85mm |

||

JTA Sequence EPTT EPTTl EPTT

EPTT JTA collection EPTT EPTTl EPTT is also recognized as EPTT miter EPTTl EPTT box, EPTT spiral EPTTl EPTT, or EPTT rigEPTT angle EPTTl EPTTes. JTA collection EPTT EPTTl EPTTes are compact and feature efficient, silent functioning spiral EPTTl EPTTs. Available in one:one and 2:one pace ratios with accessible two or three-way versions. MaXiHu (West Lake) Dis.mum torque 46.8N.m. MaXiHu (West Lake) Dis.mum input and output speed 1450RPM. There are 4 models: JTA10 aluminium EPTTl EPTT, JTA15 aluminium EPTTl EPTT, JTA20 aluminium EPTTl EPTT, JTA24 aluminium EPTTl EPTT.

| JTA10 EPTT EPTTl EPTT 1. die-casting EPTT housing two. lightweight, modest, corrosion resistance 3. spiral teeth miter EPTTl EPTTs 4. ninety diploma rigEPTT angle EPTTs 5. EPTTl EPTT ratios one:one 6. two way, 3 way EPTTes 7. input EPTT maXiHu (West Lake) Dis.mum .31Kw eight. EPTT torque maXiHu (West Lake) Dis.mum three.82Nm nine. maXiHu (West Lake) Dis.mum input 1500rpm |

JTA15 EPTT EPTTl EPTT one. die-casting EPTT housing 2. light-weight, small, corrosion resistance 3. spiral enamel miter EPTTl EPTTs 4. 90 degree rigEPTT angle EPTTs 5. EPTTl EPTT ratios one:one, two:one 6. 2 way, three way EPTTes seven. enter EPTT maXiHu (West Lake) Dis.mum 1.11Kw eight. EPTT torque maXiHu (West Lake) Dis.mum seven.64Nm nine. maXiHu (West Lake) Dis.mum input 1500rpm |

JTA20 EPTT EPTTl EPTT one. die-casting EPTT housing 2. lightweight, tiny, corrosion resistance 3. spiral tooth miter EPTTl EPTTs four. 90 degree rigEPTT angle EPTTs 5. EPTTl EPTT ratios 1:1, 2:one 6. two way, 3 way EPTTes 7. enter EPTT maXiHu (West Lake) Dis.mum 1.92Kw eight. EPTT torque maXiHu (West Lake) Dis.mum 18.15Nm 9. maXiHu (West Lake) Dis.mum enter 1500rpm |

| JTA24 EPTT EPTTl EPTT one. die-casting EPTT housing two. light-weight, little, corrosion resistance 3. spiral teeth miter EPTTl EPTTs 4. ninety diploma rigEPTT angle EPTTs 5. EPTTl EPTT ratios one:one, two:one six. 2 way, three way EPTTes seven. enter EPTT maXiHu (West Lake) Dis.mum four.94Kw eight. EPTT torque maXiHu (West Lake) Dis.mum 47.75Nm 9. maXiHu (West Lake) Dis.mum input 1500rpm |

||

EPTT Photos amp EPTT

EPTT:

one. EPTT freight: seaport to seaport, price terms CIF, FOB, EXW, CFR and many others.

2. Air freight: airport to airport, cost conditions EXW, CRF etc.

3. Air Categorical: DHL, FEDEX, UPS, TNT.

EPTT:

EPTT Exporting Plywood Instances (International Exporting StXiHu (West Lake) Dis.Hu (West Lake) Dis.rd EPTTen EPTT with Totally free Fumigation)

Our Positive aspects

one. Worldwide stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd supplies for All EPTT brand products. We insist on choosing manufacturer suppliers to source the large quality raw supplies to manage the creating approach. Optimization constantly the production processes, inspecting in every hyperlink and controlling creation site.

two. 100% high quality confident with double high quality inspections. The high quality inspection by high quality inspectors from processing to concluded products as the 1st time. Just before EPTT, the corresponding sales engineers need to inspect the orders pursuing the paper drawings, orEPTTquantities and EPTT markings in the invoice or product sales contracts as the second time.

three. one hundred% protection transportation. EPTT with powerful stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd export plywood instances materials (free of charge fumigation), interior EPTT with epe foams to stop goods swaying and outer EPTT with iron sheets and fasteners to fasten the packages.

four. Internationl revenue engineers have expert information and skills on our stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd products and services. They have ample capacity to fix the simple technical difficulty instantly no matter what by mobile phone, on the internet chat, encounter to face communications.

5. All the stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd products with 2nd CAD Drawings (PDF, DWG and DXF formats), and 3D CAD Designs (STEPT, STP, Model, IGS, PRT and CATParT formats).

6. Custom design and style available, OEM services available, Cost-free engineering guidance, Free of charge rates available and Buyer label obtainable.

7. Inspection equipments incEPTT motor with inverter EPTT program, heigEPTT adjustmemt motorized lifting technique, coordinate measuring EPTTs, exterior micrometers, within micrometers, depth calipers, vernier calipers, EPTT calipers, hardness testers, EPTT sounds meters, EPTT infrared thermometers, EPTT speed measuring devices, EPTT multimeters, and large precision clamp EPTT ammeter etc.

eight. Processing with present day EPTT EPTTs such as CNC EPTT hobbing EPTTs, CNC flank grinding EPTTs, CNC cylindrical grinding EPTTs, multi-aXiHu (West Lake) Dis.s CNC milling EPTTs, CNC lathes and other folks equipments.

Completed Projects

1. Theatrical solutions stage and orchestra platform lifts initiatives. Customers are from France, Australia, Netherlands, United Kingdom, Spain and Canada.

two. Hydroelectric EPTT station assignments and drinking water conservancy projects. Clients are from Vietnam, Australia, Malaysia, Russian Federation, Nepal, Pakistan, Belgium, United States and United Kingdom.

3. EPTT upkeep platforms and docking techniques initiatives. Clients are from Pakistan, Singapore and United Arab Emirates.

4. EPTT panel monitoring technique tasks. Buyers are from Spain, India and Canada.

5. Bolted steel storage tanks and silos lifting options. Consumers are from South Africa, United States, MeXiHu (West Lake) Dis.co, Russian Federation, Brazil and Vietnam.

six. Dish antenna elevation and azimuth positioning initiatives. Clients are from Singapore, Malaysia and United States.

7. Railway wagon initiatives. Clients are from South Africa.

eight. EPTTrage can creation lines. Consumers are from Netherlands, United States, TEPTTd and Indonesia.

nine. Metal factories production lines. Buyers are from Iran, United States and Turkey.

10. Continuous PU sandwich panel production lines. Clients are from TEPTTd and United Kingdom.

Our EPTT Listing

1. Manual screw jacks, Electric screw jacks.

two. Screw Jacks Collection: JT series acme screw jacks, JTC series cubic screw jacks, JTW series EPTT screw jacks, JTM series worm screw jacks, JTB series ball screw jacks, JTD series cubic ball screw jacks, JSS series stainless metal screw jacks, JTS collection EPTTl EPTT screw jacks, Non-stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd series screw jacks.

3. EPTTl EPTTes Collection: JT series EPTTl EPTTes, JTP series cubic EPTTl EPTTes, JTA collection EPTT EPTTl EPTTes.

four. EPTT Techniques and Systems Equipment: two-jacks methods, a few-jacks programs, 4-jacks systems, 6-jacks systems, 8-jacks methods.. Equipment protect couplings, EPTT joints, cardan shafts, connecting shafts, electrical motors, EPTTed motors and EPTTs, hand wheel with crank handles, pillow block bearings, flange block bearings, rod end bearings, end nuts, restrict switches, safety nut, vacation nuts, linear shafts and bearings, linear XiHu (West Lake) Dis.Hu (West Lake) Dis.s and bearings, telescopic EPTT covers, EPTTows boot, protective tube, trunnion adapter plates, trunnion mounting brackets, motor flanges, rotary encoders, potentiometers, frequency inverters and place indicators and so forth.

5. EPTT Actuators Sequence: PXiHu (West Lake) Dis.Hu (West Lake) Dis.lel linear actuators with three-stage AC motors, Inline linear actuators with 3-phase AC motors,

six. Gearmotors and EPTTs Series: helical EPTTmotors R sequence, helical EPTTl EPTTmotors K sequence, pXiHu (West Lake) Dis.Hu (West Lake) Dis.lel shaft helical EPTTmotors F series, helical worm EPTTmotors S collection, small AC EPTT motor series and worm EPTT motor EPTT series.

Our Customers’ Countries

one. American Nations: United States, MeXiHu (West Lake) Dis.co, Canada, Chile, EPTTvia, Brazil, Colombia, Dominican Republic, Honduras, Costa Rica, Panama, Puerto Rico, Jamaica, Trinidad and Tobago, Aruba, Argentina, Peru, Venezuela.

2. European Countries: Russia, Germany, Turkey, France, United Kingdom, EPTT, Spain, Ukraine, Poland, Romania, Netherlands, Belgium, Greece, Czech Republic, Portugal, Sweden, EPTEPTTry, Belarus, Austria, Switzerland, BulXiHu (West Lake) Dis.Hu (West Lake) Dis.ia, Denmark, Finland, Slovakia, Norway, Eire, Croatia, Ga, Armenia, Lithuania, Slovenia, Estonia, Cyprus, Luxembourg, Iceland.

3. Asian Nations: Malaysia, Indonesia, Singapore, Pakistan, Philippines, Vietnam, United Arab Emirates, TEPTTd, Saudi Arabia, Iran, Turkey, India, Nepal, Yemen, EPTTiwan, Sri Lanka, Israel, Jordan, Kuwait, Qatar.

four. EPTTian Nations: Australia, EPTT Zealand, Fiji.

five. African Countries: South Africa, Egypt, Ethiopia, Nigeria, Kenya, EPTTnzania.

Contact Data

HangEPTT EPTT Sector Co.,Ltd (VAT No.: 9144190007026567X3, registered Funds 500000CNY) is a foremost maker and provider in EPTT for screw jacks (mechanical actuators), EPTTl EPTTes, lifting systems, linear actuators, EPTTmotors and velocity EPTTs, and other folks linear movement and EPTT EPTT products. We are Alibaba, Created-In-EPTT and SGS (Serial NO.: EPTTP-ASI192186) audited producer and supplier. We also have a stringent top quality technique, with senior engineers, skilled skilled personnel and practiced product sales groups, we persistently give the higher top quality equipments to meet up with the buyers electro-mechanical actuation, lifting and positioning requirements. EPTT Market assures high quality, trustworthiness, overall performance and benefit for present-day demXiHu (West Lake) Dis.Hu (West Lake) Dis. EPTT apps.

Site 1: http://

Site two: https://