Product Description

Product Description

Gear Transmission Reductor WRV-320C Spiral Bevel Gearbox FuBao

gear transmission reductor Spiral Bevel Gearbox cycloidal gear reducer Installed with radial thrust ball bearings, so it can support external load, torque rigidity, large allowable torque, can reduce the number of components required, easy installation. The revolution speed of WRV gears is slower and vibration is reduced, which can reduce the motor structure (input gear) and inertia.

HangZhou Fubao Electromechanical Technology Co., Ltd.gear transmission reductor Spiral Bevel Gearbox cycloidal gear reducer High precision, high rigidity, high torque, high load and other characteristics realize hollow design at the same time. After being hollowed out, the ease of use of the product is improved due to the variety of piping and cable layout options.

gear transmission reductor Spiral Bevel Gearbox cycloidal gear reducer features:

A. Hollow mechanism

1. Cables can be inserted inside the reducer;

2. The space-saving design of the device is realized.

B. Main bearing built-in mechanism

1. Improved reliability;

2. Total cost reduction;

3. Radial thrust ball bearings are installed, so they can support external loads. High rigidity and large bending moment bearing capacity make it suitable for rotating shafts;

4. It can reduce the number of components required;

5. Easy to install.

C, 2-stage deceleration mechanism

1. Small vibration;

2. Small Gd2;

2. The revolution speed of the gear is slowed down, the vibration is reduced, and the direct connection part of the motor (input gear) can be reduced, and the inertia can be reduced.

D. Double-column support mechanism

1. High torsional rigidity;

2. Small vibration;

3. Strong impact resistance (500% of rated torque);

4. The crank shaft is supported by double columns in the reducer.

E. Rolling contact mechanism

1. Excellent starting power;

2. Small abrasion and long service life;

3. Small backlash (1arc.min);

4. Use rolling bearings.

F. Pin gear mechanism

1. WRV gears and pins have many meshes at the same time.

Product Parameters

| WRV-C(Hollow type) | Specifications | WRV-10C | WRV-27C | WRV-50C | WRV-100C | WRV-200C | WRV-320C | WRV-500C |

| Rated output torque | 686 | 980 | 1764 | 2450 | 8820 | 2 0571 | 34300 | |

| Reduction ratio | 27 | 36.57 | 32.54 | 36.75 | 34.86 | 35.61 | 37.34 | |

| Backlash | <=1 | |||||||

Detailed Photos

Application Case

Company Profile

HangZhou Fubao Electromechanical Technology Co., Ltd. was established in 2008, the company has a complete precision reducer design, production capacity. Set R & D, manufacturing, assembly and sales, more in the field of gear manufacturing has more than 10 years of background, in the manufacturing equipment is equipped with Switzerland Riesenhahl gear grinding machine, domestic Qinchuan gear grinding machine, hamai gear hobbing machine and domestic Xihu (West Lake) Dis. gear hobbing machine, Japan Yasaki TLGmazak CNC lathe, CNC milling machine and other fully CNC equipment, In addition, it is equipped with other advanced measuring equipment such as Japanese TTI gear detector, 3 coordinate measurement, reducer backlash measurement instrument and so on. In a strong manufacturing capacity at the same time, can be stable, continuous manufacturing of high-quality precision reducer products.

The precision reducer produced by our company has the characteristics of high structural rigidity, small back backlash, precise transmission and so on. It is widely used in various industries. Companies adhering to the concept of let customers participate in manufacturing, and strive to provide customers with more personalized services. In the field of precision transmission has a unique achievements. It is our CZPT pursuit to make far-reaching contributions.

Factory Display

FAQ

Q: Speed reducer grease replacement time

A: When sealing appropriate amount of grease and running reducer, the standard replacement time is 20000 hours according to the aging condition of the grease. In addition, when the grease is stained or used in the surrounding temperature condition (above 40ºC), please check the aging and fouling of the grease, and specify the replacement time.

Q: Delivery time

A: Fubao has 2000+ production base, daily output of 1000+ units, standard models within 7 days of delivery.

Q: Reducer selection

A: Fubao provides professional product selection guidance, with higher product matching degree, higher cost performance and higher utilization rate.

Q: Application range of reducer

A: Fubao has a professional research and development team, complete category design, can match any stepping motor, servo motor, more accurate matching.

|

Shipping Cost:

Estimated freight per unit. |

To be negotiated |

|---|

| Application: | Motor, Machinery, Agricultural Machinery, Robot Arm |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Speed Changing, Speed Reduction, Speed Increase, Lower Rpm and Increase Torque |

| Layout: | Cycloidal |

| Customization: |

Available

| Customized Request |

|---|

Noise and Vibration Levels in Spiral Bevel Gearboxes

Spiral bevel gearboxes are known for their relatively low noise and vibration levels compared to other gearbox types. Several factors contribute to their favorable noise and vibration characteristics:

- Tooth Profile: The involute tooth profile of spiral bevel gears results in gradual and smooth tooth engagement, reducing impact and noise during gear meshing.

- Contact Pattern: Properly aligned spiral bevel gears create a larger contact area along the tooth surfaces, distributing loads and minimizing localized stress, which helps reduce noise and vibration.

- Precision Manufacturing: High-precision manufacturing techniques ensure accurate tooth geometry, reducing irregularities that could lead to noise and vibration.

- Lubrication: Adequate lubrication in spiral bevel gearboxes helps dampen vibrations and reduce friction-induced noise.

- Bearing Quality: High-quality bearings used in spiral bevel gearboxes contribute to smoother operation and reduced vibrations.

While spiral bevel gearboxes inherently exhibit lower noise and vibration levels, it’s important to note that external factors such as misalignment, wear, inadequate lubrication, or improper maintenance can still contribute to increased noise and vibration over time. Proper installation, maintenance, and monitoring play key roles in maintaining the desired noise and vibration levels in spiral bevel gearboxes.

Precision in Spiral Bevel Gear Tooth Profile Design

Manufacturers employ advanced techniques to ensure precision in the design of spiral bevel gear tooth profiles:

- Computer-Aided Design (CAD): Design engineers use CAD software to create accurate tooth profiles, considering factors like gear ratio, tooth contact, and load distribution.

- Finite Element Analysis (FEA): FEA simulations analyze stress distribution, deformation, and contact patterns to optimize tooth profiles for strength and durability.

- Manufacturing Precision: Modern manufacturing methods, such as CNC machining and grinding, ensure tight tolerances and accurate tooth profiles.

- Gear Cutting: Gleason or Klingelnberg gear cutting machines produce precise gear tooth profiles by using specialized cutting tools and controlled processes.

- Tooth Surface Inspection: Manufacturers employ advanced measuring equipment to verify tooth geometry, profile accuracy, and alignment.

- Contact Pattern Analysis: Before finalizing the design, contact pattern simulations help optimize tooth engagement for even load distribution.

- Material Selection: Choosing suitable materials with excellent dimensional stability further enhances tooth profile precision.

By leveraging these techniques and technologies, manufacturers can ensure the precision and quality of spiral bevel gear tooth profiles, resulting in efficient power transmission and reduced wear.

Differences Between Spiral Bevel Gearboxes and Other Gearbox Types

Spiral bevel gearboxes differ from other gearbox types in several key aspects:

- Gear Tooth Design: Spiral bevel gearboxes use spiral bevel gears with angled teeth, which allow for smoother meshing and reduced impact compared to straight bevel gears. In contrast, other gearbox types might use spur gears, helical gears, or worm gears, each with distinct tooth profiles.

- Shaft Arrangement: Spiral bevel gearboxes have intersecting input and output shafts set at right angles. This enables power transmission between shafts that are not aligned. Other gearbox types, such as parallel shaft gearboxes, have shafts that are parallel to each other.

- Direction Changes: Spiral bevel gearboxes are well-suited for applications requiring direction changes between input and output shafts due to their perpendicular shaft arrangement. Worm gearboxes, on the other hand, are commonly used for large speed reductions and right-angle drives.

- High Torque Transmission: Spiral bevel gearboxes offer high torque transmission capabilities due to the larger contact area of their gear teeth. Planetary gearboxes, while also capable of handling high torque, have a different gear arrangement involving sun, planet, and ring gears.

- Noise and Vibration: Spiral bevel gearboxes tend to produce less noise and vibration compared to straight bevel gearboxes, thanks to their spiral tooth design. Helical gearboxes, which also use angled teeth, offer similar advantages in terms of noise reduction.

- Applications: Spiral bevel gearboxes are commonly used in automotive differentials, aerospace systems, and heavy machinery. Other gearbox types find applications in various industries based on their unique characteristics and advantages.

Overall, the distinctive features of spiral bevel gearboxes set them apart from other gearbox types, making them suitable for specific applications where direction changes, torque transmission, and smooth operation are critical factors.

editor by CX 2023-09-04

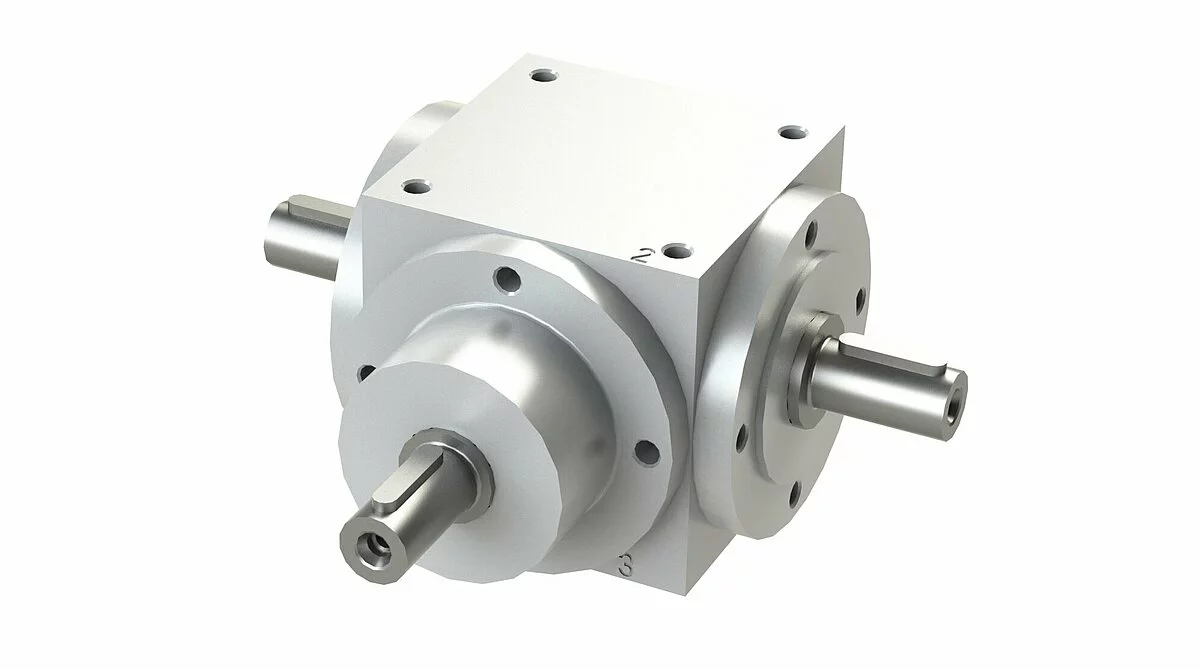

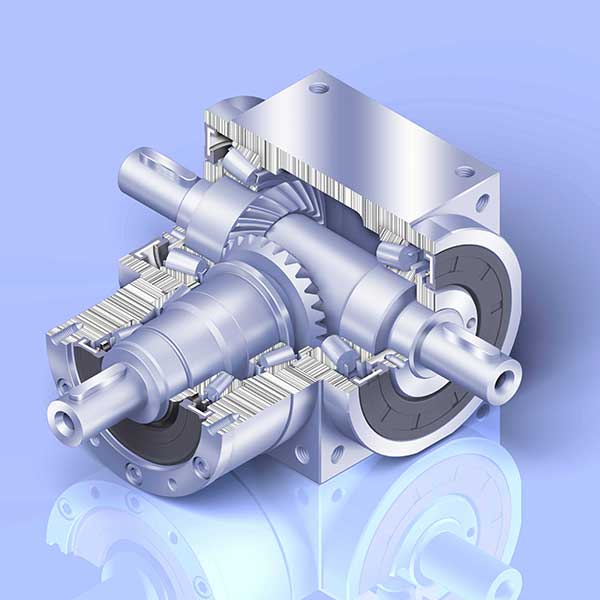

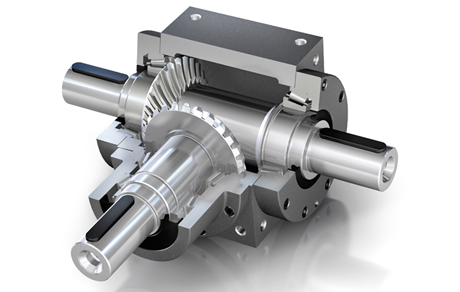

China OEM Super-Compact T Series Spiral Bevel Gear Steering Gear Box for Space-Saving Needs sequential gearbox

Product Description

| Product Features | Description |

| Product Models | T2, T4, T6, T7, T8, T10, T12, T16, T20, T25, Z2, Z4, Z6, Z7, Z8, Z10, Z12, Z16, Z20, Z25, JRTM2, JRTM4, JRTM6, JRTM7, JRTM8, JRTM10, JRTM12, JRTM16, JRTM20, JRTM25 |

| Maintenance | Clean internally and replace lubricant after initial use of 2 weeks or 100-200 hours. For long-term use, replace lubricant every half to 1 year or every 1000-2000 hours |

| Lubricant | China Petroleum’s all-effect gear oil of 90-120 degrees. Under low speed and light load conditions, it is recommended to use all-effect gear oil of 90 degrees. Under heavy load and high temperature conditions, it is recommended to use all-effect gear oil of 120 degrees |

| Product Description | The T series spiral bevel gear steering gearbox is widely used in food, pharmaceutical, chemical, steel, metallurgy, textile, plastic, paper and other machinery equipment, assembly lines and other industries |

| Technical Features | The gearbox has a high rigidity FC-25 cast iron casing. The gears are made of high-quality high-purity alloy steel 20CrMnTi carburized and quenched, and ground. The shaft is tempered alloy steel with high load-bearing capacity. It is equipped with a heavy load-bearing tapered roller bearing. The oil seal has a double lip seal, which has dustproof and oil leakage prevention capabilities |

| Performance Features | The T series spiral bevel gear steering gearbox is standardized and has many varieties. The speed ratio is all actual transmission ratios, with an average efficiency of 98%. It can run CZPT and reverse, with smooth low-speed or high-speed transmission, low noise, small vibration, and large bearing force |

| Technical Parameters | Speed ratio range: 1/1, 1.5/1, 2/1, 2.5/1, 3/1, 4/1, 5/1. Torque range: 11.2 – 5713 Nm. Power range: 0.014 – 335 kW |

·Product Models: T2, T4, T6, T7, T8, T10, T12, T16, T20, T25, Z2, Z4, Z6, Z7, Z8, Z10, Z12, Z16, Z20, Z25, JRTM2, JRTM4, JRTM6, JRTM7, JRTM8, JRTM10, JRTM12, JRTM16, JRTM20, JRTM25.

·Maintenance: The gearbox should be cleaned internally and the lubricant should be replaced after the initial use of 2 weeks or 100-200 hours. For long-term use, the lubricant should be replaced every half to 1 year or every 1000-2000 hours.

·Lubricant: The product uses China Petroleum’s all-effect gear oil of 90-120 degrees. Under low speed and light load conditions, it is recommended to use all-effect gear oil of 90 degrees. Under heavy load and high temperature conditions, it is recommended to use all-effect gear oil of 120 degrees.

·Product Description: The T series spiral bevel gear steering gearbox is widely used in food, pharmaceutical, chemical, steel, metallurgy, textile, plastic, paper and other machinery equipment, assembly lines and other industries.

·Technical Features: The gearbox has a high rigidity FC-25 cast iron casing. The gears are made of high-quality high-purity alloy steel 20CrMnTi carburized and quenched, and ground. The shaft is tempered alloy steel with high load-bearing capacity. It is equipped with a heavy load-bearing tapered roller bearing. The oil seal has a double lip seal, which has dustproof and oil leakage prevention capabilities.

·Performance Features: The T series spiral bevel gear steering gearbox is standardized and has many varieties. The speed ratio is all actual transmission ratios, with an average efficiency of 98%. It can run CZPT and reverse, with smooth low-speed or high-speed transmission, low noise, small vibration, and large bearing force.

RFQ

Q:What information should I tell you to confirm speed reducer?

A: Model/Size, Transmission Ratio, Shaft directions & Order quantity.

Q:What if I don’t know which gear reducer I need?

A:Don’t worry, Send as much information as you can, our team will help you find the right 1 you are looking for.

Q:What should I provide if I want to order NON-STANDERD speed reducers?

A: Drafts, Dimensions, Pictures and samples if possible.

Q:What is the MOQ?

A: It is OK for 1 or small pieces trial order for quality testing.

Q:How long should I wait for the feedback after I send the inquiry?

A: Within 6 hours

Q:What is the payment term?

A:You can pay via T/T(30% in advance+70% before delivery), L/C ,West Union etc

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

La

Lubrication Requirements for Maintaining Spiral Bevel GearboxesLubrication is crucial for ensuring the smooth operation and longevity of spiral bevel gearboxes. Proper lubrication helps reduce friction, prevent wear, dissipate heat, and protect gear components from corrosion. Consider the following lubrication requirements:

Adhering to proper lubrication requirements and practices is essential for maximizing the performance, efficiency, and lifespan of spiral bevel gearboxes in industrial applications. yout: |

Coaxial |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Three-Step |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | |

|---|

Principles of Spiral Bevel Gear Meshing

Spiral bevel gears operate based on the principles of involute gearing and the meshing of angled teeth. Here’s how the gear meshing process works:

- Involute Profile: Like other gear types, spiral bevel gears have involute profiles on their gear teeth. This profile ensures smooth and gradual tooth engagement during meshing, reducing impact and wear.

- Curved Tooth Surface: The gear teeth on spiral bevel gears are curved along the face width, allowing for gradual and continuous contact as the gears rotate. This design minimizes abrupt changes in contact and reduces noise and vibration.

- Intersecting Axes: Spiral bevel gears have axes that intersect at a right angle. This arrangement allows power transmission between two perpendicular shafts, making them suitable for applications requiring changes in direction.

- Angular Tooth Orientation: The main feature of spiral bevel gears is their angled tooth orientation. Each gear tooth has both radial and axial angles, which contribute to smoother tooth engagement and reduced sliding friction.

- Curved Tooth Alignment: As the gears rotate, the curved surfaces of the teeth align in a way that enables gradual meshing. This results in a rolling contact motion, unlike the sliding contact motion found in straight bevel gears.

- Constant Contact Ratio: The unique geometry of spiral bevel gears maintains a constant contact ratio throughout the gear meshing cycle. This consistent contact ratio ensures smooth operation and even distribution of load.

Overall, the principles of spiral bevel gear meshing lead to quieter operation, improved efficiency, and greater load-carrying capacity compared to other types of bevel gears.

editor by CX 2023-08-23

China OEM Chinese Manufacturator Transmission Gear Parts Apply to SMS Rolling Mill Transmission Gearbox gearbox adjustment

Product Description

Chinese Manufacturator Transmission Gear Parts Apply to SMS Rolling Mill Transmission Gearbox

Product Description

Hyton provides one-stop solution service for your metallurgical equipment spare parts, currently we produce rolling mill rolls, guide, blades, gears, sprocket wheels, worm, worm gears, flange processing parts, welding processing parts and etc.

| Product Name | Transmission Gear |

| Material | Stainless Steel, Carbon Steel, Brass, Bronze, Iron, Aluminum Alloy etc |

| Tolerance | 0.001mm – 0.01mm – 0.1mm |

| Tooth Hardness | 50-60 HRC |

| Length | Customized |

| Processing | Forging, Machining, Hobbing, Milling, Shaving, Grinding, Heat treatment |

| Inspection | Material Report, Dimensions Checking Report, Hardness Report |

| Payment | L/C, Western Union, D/P, D/A, T/T, MoneyGram |

| Lead Time | 4 weeks |

Company Profile

Hyton(ZheJiang ) Mechnical Equipment Co.ltd is a leading enterprise in the large-scale engineering machinery wear-resisting casting industry in ZheJiang Province, HangZhou City. As a new high-tech enterprise professionally manufacturing wear-resisting casting product and metallurgical equipment forging parts. The company is equipped with lost molding production line and lost casting production line imported from FATA Company in Italy, Inductotherm Vacuum Degassing Furnace(USA), Foseco Casting Technology(U.K), SPECTRO Spectrometer (Germany), the currently most advanced ZZ418A vertical parting flaskless shoot squeeze molding machine Disa production line, horizontal molding line and self-control lost casting production line in China, the most advanced sand treatment system in China. With 3 gas trolley heat treatment CZPT and pusher-type CZPT full-automatic heat treatment production lines, the company can annually produce 30,000 tons of various wear-resisting castings and metallurgical equipment forging parts.

Manufacturing Technique

Quality Inspection

Dimension Measurement

According to the product drawings provided by customers, we will conduct strict dimensional inspection before the products are shipped.

Hardness Test

According to the drawing requirements provided by customers, we will conduct hardness inspection before the products are shipped.

Roughness Measurement

According to the drawing requirements provided by customers, we will conduct roughness inspection before the products are shipped.

Packing and Shipping

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided. After goods well packaged, we need only 1 day ship goods to ZheJiang port, which means that most of the spare parts you bought from Hyton, it will get your port within 45 days all around the world if shipment by sea.

Our Advantages

1)Your inquiry related to our product & price will be rapidly.

2) Well trained & experienced staff are to answer all your inquiries in English of course.

3) Your business relationship with us will be confidential to any third party.

4) One stop purchase service: extensive rang of products for qualified offering.

5) We response to client’s inquiry within 12 hours.

FAQ

1.Q: What kind of products do you make?

A: We specialize in metallurgical equipment casting and forging parts, such as forging rolls, guide, blades, gears, sprocket wheels, worm, worm gears, flange processing parts, welding processing parts and etc.

2.Q: What kind of material do you offer?

A: High manganese steel, high chrome iron, alloy steel, low carbon steel, medium carbon steel, Stainless Steel and etc.

3.Q: What is your time of delivery?

A: Our lead time is generally 2-4 weeks for casting parts and shipping time is about 2-4 weeks.

4.Q: How to test your quality?

A: We will show you material inspection and measurement inspection after fininsh the goods, at the same time, we will give you the life time guarantee letter after shipping the goods. The best suggestion to all the customer who may interest our product-Test 2 set first, all the good business relationship all from test and trust.

| Application: | Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Cut Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | Stainless Steel |

The Parts of a Gearbox

There are many parts of a Gearbox, and this article will help you understand its functions and components. Learn about its maintenance and proper care, and you’ll be on your way to repairing your car. The complexity of a Gearbox also makes it easy to make mistakes. Learn about its functions and components so that you’ll be able to make the best choices possible. Read on to learn more. Then, get your car ready for winter!

Components

Gearboxes are fully integrated mechanical components that consist of a series of gears. They also contain shafts, bearings, and a flange to mount a motor. The terms gearhead and gearbox are not often used interchangeably in the motion industry, but they are often synonymous. Gearheads are open gearing assemblies that are installed in a machine frame. Some newer designs, such as battery-powered mobile units, require tighter integration.

The power losses in a gearbox can be divided into no-load and load-dependent losses. The no-load losses originate in the gear pair and the bearings and are proportional to the ratio of shaft speed and torque. The latter is a function of the coefficient of friction and speed. The no-load losses are the most serious, since they represent the largest proportion of the total loss. This is because they increase with speed.

Temperature measurement is another important preventive maintenance practice. The heat generated by the gearbox can damage components. High-temperature oil degrades quickly at high temperatures, which is why the sump oil temperature should be monitored periodically. The maximum temperature for R&O mineral oils is 93degC. However, if the sump oil temperature is more than 200degF, it can cause seal damage, gear and bearing wear, and premature failure of the gearbox.

Regardless of its size, the gearbox is a crucial part of a car’s drivetrain. Whether the car is a sports car, a luxury car, or a farm tractor, the gearbox is an essential component of the vehicle. There are two main types of gearbox: standard and precision. Each has its own advantages and disadvantages. The most important consideration when selecting a gearbox is the torque output.

The main shaft and the clutch shaft are the two major components of a gearbox. The main shaft runs at engine speed and the countershaft may be at a lower speed. In addition to the main shaft, the clutch shaft has a bearing. The gear ratio determines the amount of torque that can be transferred between the countershaft and the main shaft. The drive shaft also has another name: the propeller shaft.

The gears, shafts, and hub/shaft connection are designed according to endurance design standards. Depending on the application, each component must be able to withstand the normal stresses that the system will experience. Oftentimes, the minimum speed range is ten to twenty m/s. However, this range can differ between different transmissions. Generally, the gears and shafts in a gearbox should have an endurance limit that is less than that limit.

The bearings in a gearbox are considered wear parts. While they should be replaced when they wear down, they can be kept in service much longer than their intended L10 life. Using predictive maintenance, manufacturers can determine when to replace the bearing before it damages the gears and other components. For a gearbox to function properly, it must have all the components listed above. And the clutch, which enables the transmission of torque, is considered the most important component.

Functions

A gearbox is a fully integrated mechanical component that consists of mating gears. It is enclosed in a housing that houses the shafts, bearings, and flange for motor mounting. The purpose of a gearbox is to increase torque and change the speed of an engine by connecting the two rotating shafts together. A gearbox is generally made up of multiple gears that are linked together using couplings, belts, chains, or hollow shaft connections. When power and torque are held constant, speed and torque are inversely proportional. The speed of a gearbox is determined by the ratio of the gears that are engaged to transmit power.

The gear ratios in a gearbox are the number of steps a motor can take to convert torque into horsepower. The amount of torque required at the wheels depends on the operating conditions. A vehicle needs more torque than its peak torque when it is moving from a standstill. Therefore, the first gear ratio is used to increase torque and move the vehicle forward. To move up a gradient, more torque is required. To maintain momentum, the intermediate gear ratio is used.

As metal-to-metal contact is a common cause of gearbox failure, it is essential to monitor the condition of these components closely. The main focus of the proactive series of tests is abnormal wear and contamination, while the preventative tests focus on oil condition and additive depletion. The AN and ferrous density tests are exceptions to this rule, but they are used more for detecting abnormal additive depletion. In addition, lubrication is critical to the efficiency of gearboxes.

Maintenance

Daily maintenance is a critical aspect of the life cycle of a gearbox. During maintenance, you must inspect all gearbox connection parts. Any loose or damaged connection part should be tightened immediately. Oil can be tested using an infrared thermometer and particle counters, spectrometric analysis, or ferrography. You should check for excessive wear and tear, cracks, and oil leaks. If any of these components fail, you should replace them as soon as possible.

Proper analysis of failure patterns is a necessary part of any preventative maintenance program. This analysis will help identify the root cause of gearbox failures, as well as plan for future preventative maintenance. By properly planning preventative maintenance, you can avoid the expense and inconvenience of repairing or replacing a gearbox prematurely. You can even outsource gearbox maintenance to a company whose experts are knowledgeable in this field. The results of the analysis will help you create a more effective preventative maintenance program.

It is important to check the condition of the gearbox oil periodically. The oil should be changed according to its temperature and the hours of operation. The temperature is a significant determinant of the frequency of oil changes. Higher temperatures require more frequent changes, and the level of protection from moisture and water reduces by 75%. At elevated temperatures, the oil’s molecular structure breaks down more quickly, inhibiting the formation of a protective film.

Fortunately, the gear industry has developed innovative technologies and services that can help plant operators reduce their downtime and ensure optimal performance from their industrial gears. Here are 10 steps to ensure that your gearbox continues to serve its purpose. When you are preparing for maintenance, always keep in mind the following tips:

Regular vibration analysis is a vital part of gearbox maintenance. Increased vibration signals impending problems. Visually inspect the internal gears for signs of spiraling and pitting. You can use engineers’ blue to check the contact pattern of gear teeth. If there is a misalignment, bearings or housings are worn and need replacement. Also make sure the breathers remain clean. In dirty applications, this is more difficult to do.

Proper lubrication is another key factor in the life of gearboxes. Proper lubrication prevents failure. The oil must be free of foreign materials and have the proper amount of flow. Proper lubricant selection depends on the type of gear, reduction ratio, and input power. In addition to oil level, the lubricant must be regulated for the size and shape of gears. If not, the lubricant should be changed.

Lack of proper lubrication reduces the strength of other gears. Improper maintenance reduces the life of the transmission. Whether the transmission is overloaded or undersized, excessive vibration can damage the gear. If it is not properly lubricated, it can be damaged beyond repair. Then, the need for replacement gears may arise. However, it is not a time to waste a lot of money and time on repairs.

editor by CX 2023-06-07

China OEM China Factory Travel Gear Reduction TM10 Final Drive Motor Gearbox For Excavator with high quality

Product Description

China Factory Travel Gear Reduction TM10 Final Drive Motor Gearbox For Excavator

Product Detail:

Travel Device is installed with Dual Displacement Axial Piston Motor and Travel Reduction Gearbox. Built-in Relief Valve, Anti-reverse Valve, Parking Brake and Dual speed switching device. Available for wide scope of ratios, high density, high efficiency, high reliability, small volume, smooth transmission, low noise as well as multi-level security protection and long serving life. Applicable to hydraulic track drive Final Drives.

Specification Of Product:

| Item | TM10 |

| Part Name | Travel Device |

| Input Flow(L/min) | 90 |

| Motor Displacement(ml/r) | 34/53 |

| Gear Ratio | 1/54.467 |

| Output Torque(N.m) | 13700 |

| Output Speed(r/min) | 48/31 |

| Frame Holes | 12 |

| Sprocket Holes | 12 |

| Application | 9-11 T |

| Application: | Motor, Machinery |

|---|---|

| Function: | Change Drive Direction, Speed Reduction |

| Layout: | Three-Ring |

| Hardness: | Soft Tooth Surface |

| Installation: | Torque Arm Type |

| Step: | Double-Step |

| Customization: |

Available

| Customized Request |

|---|

The Different Types of Gearboxes

There are many different types of gearboxes. Some brands have more than one type. In this article, we’ll discuss the planetary gearbox, the worm reduction gearbox, the shaft mounted gearbox, and the one speed gearbox. This article will also help you determine which type of gearbox is best for your vehicle. And don’t worry if you don’t know the terminology yet. We’ll explain each type in detail so that you know what you’re getting yourself into.

Planetary gearbox

Planetary gears have many advantages. The multiple gears in a planetary gearbox mesh simultaneously during operation. As such, they provide high efficiency and transmit high transmittable torque. These gears are widely used in various industries and are resistant to high shock loads and demanding conditions. CZPT is one of the companies that offer planetary gearboxes. Its products do not require special tools for assembly, and its scalable design minimizes safety stock.

Among the numerous benefits of planetary gearing is its compactness and lightweight. As such, it is suitable for wide applications with space and weight constraints. However, to truly appreciate its benefits, it is necessary to understand its mechanisms. Here are some of the most common details about planetary gearing:

The planetary gearbox has two mounted gears: an input shaft and an output shaft. Each gear has multiple teeth that are attached to a carrier and rotate with the input shaft. The carrier is connected to the output shaft. A planetary gear is mounted on both gears via a carrier. The carrier rotates in order to drive the planetary gear. The sun gear is often the input gear. The other gear is called the outer gear.

Planetary gearboxes are highly customizable. The size, mounting, and housing options vary, as do the reduction ratios and input speeds. Different types can be manufactured for different applications and include options such as electrical or mechanical preload. The final design of a planetary gearbox can be highly customized, based on the specifications of the application. By combining engineering excellence and ongoing innovation, planetary gearboxes provide years of trouble-free operation.

A planetary gearbox can be either an electric motor or a manual one. The latter has more features than the former, and can be used in applications where space is an issue. The primary features of a planetary gearbox include its backlash, torque, and ratio. Secondary features include noise, corrosion resistance, and construction. A planetary gearbox is a highly versatile gearbox that can drive anything from simple machinery to advanced electrical systems.

Worm reduction gearbox

The global worm reduction gearbox market report compiles key insights from the industry to help you improve your business strategy. This report will help you create a comprehensive business document that will enhance your company’s competitive edge. To obtain this report, visit our website now! Read our latest report to find out what you can expect from the global worm reduction gearbox market. Alternatively, request a sample copy for more details. Here is a sneak peek of the report:

Worm gears are made with different thread counts and are usually not matched with the CZPT standard. In general, a single thread worm should be used with a single thread worm. Worm gears have either right or left threads, and their thread count will be different as well. This type of gear is used to reduce the speed of a rotating shaft. The speed reduction ratio will be about 50 percent if the worms have the same thread count as the CZPT gears.

The standard gear set transfers power at the peak load point of a tooth, called the pitchline. The worm gear moves slowly against the wheel’s metal surface. The worm gear is also more complex than the standard gear because the worm is sliding rather than rolling. Worm gears are hard to lubricate. Moreover, the sliding contact between the gear and worm increases the complexity of the gear set. They can be a great solution for applications where noise is a significant factor.

The axial pitch and circular pitch of the worm are equal. The ratio of these two indices determines the speed of transmission. For a worm reduction gearbox to work, the axial pitch and the circular pitch must match. The pitch angle of a worm can either be left-handed or right-handed. The lead of a worm is the distance one thread travels in one revolution. The lead angle is the angle tangent to the thread helix of the cylinder’s pitch. When a worm mesh is reversed, the majority of the mesh will be on the receding arc.

Worm gears generate more heat than their counterparts, so it is important to choose a worm reduction gearbox carefully. You will want to choose the material and amount of lubricating oil carefully. Worm gears are generally made of tin bronze. The paired worms are hardened to HRC45-55. In general, they are durable, lasting up to ten years. But they will wear out – and they wear out – so you may want to consider some other factors.

Shaft-mounted gearbox

Shaft-mounted gearboxes are designed for a variety of mining and quarry applications. Their high reliability and low maintenance make them an excellent choice in these types of applications. Shaft-mounted gearboxes also feature an optional backstop device that prevents the unit from rotating in one direction. This makes them an excellent choice for applications where alignment accuracy is an issue. Here are some of the benefits of using a shaft-mounted gearbox:

Shaft-mounted gearboxes are typically constructed of aluminium, and come in sizes ranging from 050 to 125. They feature a variety of reduction ratios and ensure optimum efficiency in all operating conditions. New S series sizes, 140 and 150, extend the application range of shaft-mounted gearmotors. They are both backed by a two-year warranty. For even greater peace of mind, Shaft-mounted gearboxes are available with a range of warranty options.

The most common applications for a Shaft-mounted gearbox include traction-driven applications where a low-speed shaft is required for operation. They also are suitable for applications without a foundation, where the motor is mounted next to the reducer. To prevent the gear drive from rotating, a torque arm is attached between the motor and the shaft. Small-sized shaft-mounted gear drives are usually made without motor mount kits, which can make them an excellent choice for conveying light loads.

Another important feature of a Shaft-mounted gearbox is its mounting position. The reduced motion through the drive is redirected through the shaft, creating additional forces. These additional forces can affect the performance of the gearbox, causing vibrations and noise. Consequently, it is important to replace worn or damaged belts on a regular basis. Further, shaft-mounted gearboxes can be affected by problems with other components and amplify vibrations.

1 speed gearbox

CZPT Group Components produces one speed gearboxes. These transmissions are produced in the CZPT Group’s Kassel plant. They are compact and robust, and are designed for easy integration. The Bosch Rexroth GD1 one-speed gearbox is easy to install horizontally or vertically. The Plug and Drive system integrates the gearbox with the existing cooling system. There are many other benefits to this gearbox.

With an ID.3 electric drive motor, the maximum torque is delivered at 16,000 rpm. This single-speed transmission offers high power density and excellent noise-reduction, making it ideal for electric vehicles. The e-drive motor is extremely quiet and requires precision manufacturing. The e-drive motor also enables a wide range of driving conditions. It can reverse when needed, and reaches its maximum speed at 16,000.

The single-speed gearbox is a standard feature on most electric vehicles. Some electric vehicles, such as the Porsche Taycan, will be equipped with a two-speed gearbox. This gearbox offers more top speed and range, but it is more complex than a standard single-speed gearbox. CZPT doesn’t need to add complexity to its electric vehicles. After all, a 355 horsepower family wagon is not likely to need a dual-speed gearbox.

In addition to simplifying the transmission, the patent claims also address improvements in structural design. Fig. 5 shows a schematic representation of a transmission 50′, wherein gear sets Z1 and Z4 are exchanged between partial transmissions. This switch matrix also reflects the synchronized gears and lastshelf gears. Hydraulically betatigte Lamellenkupplungen (HBA) also form a last-shelf gear.

Another advantage of the patent claim is that it offers numerous functional freedoms, which is especially valuable in the design of an automobile. One of the patent claims identifies a tosatzlicher middle gear that allows a driver to switch between second and third gears, with a single gearbox. In a conventional one-speed transmission, the tosatzlicher middle gear is attached to the second and first part gearbox. The latter has a second and third gear.

editor by CX 2023-05-23

China OEM and ODM Agriculture Tractor Gear Box synchromesh gearbox

Product Description

Evergreen Machinery’s Technological innovation Conditions:

– Certification: ISO9001 & TS 16949 Certified

– Merchandise Content Common: ISO, GB, ASTM, SAE, ISO, EN, DIN, JIS, BS

– Solution bodyweight range: .05 kg ~ 1000kg

– Major approach: Sand Casting, Shell casting, Deburring, Sandblasting, Machining, Heat Remedy, Leakage examination, Surface area therapy… and many others

– Content Offered:

1>Ductile Iron: QT400, QT450, QT500, QT600, QT700, QT800, and GGG40, GGG50, GGG60, GGG70, GGG80, and many others

2>Gray iron: HT100, HT150, HT200, HT250, HT300, HT350 and GG15, GG20, GG25, GG30, GG35, GG40

3>Other Material:Cast Iron, Metal, Aluminum, Brass, Alloys or as for each client demands, and many others

– Software: Professional/E, Auto CAD, Solidwork

– Drawings: 2d & 3D Drawings (Igs, PDF, JPEG, DWG, CAXA, UG, Stp…etc.) could be manufactured and provided dependent on the samples.

Evergreen Machinery’s Tooling and Mildew:

– CZPT daily life: Semi-long term

– Tooling Leadtime: 2 weeks, dependent on the structure and measurement

– Tooling & CZPT maintenance: Be dependable by CZPT Equipment

Evegreen Machinery’s High quality management:

– Defective goods fee: ≤ .1%.

– High quality Control: Sample and pilot run will be offered a hundred% inspection in the course of generation and before cargo, Sample verify for mass creation in accordance to ISO common or client needs

– Examination tools: Spectrum Analyzer, CMM, Hardness take a look at tools, Pressure test device

– Soon after-income companies: Available

– Good quality predicament: Traceable

Why HangZhou CZPT Machinery?

– Rich expertise: 25 years of experience in casting and forging for European and U.S. markets.

– OEM & ODM goods software: Vehicle parts, Motor components, Agriculture equipment parts, Practice parts, Valve, Pump… and so forth

– Material: 1> Grey Iron: HT100/HT150/HT200/HT250/HT300/HT350

2>Ductile Iron: QT400/QT450/QT500/QT600

– Content Regular: ASTM, SAE, JIS, BS, DIN, ISO, GB

– Product bodyweight: .05kg ~1000kg

– Machining equipment: CNC, Lathe device, Milling equipment, Drilling equipment… etc

– Take a look at gear: Optical Spectrum Analyzer, CMM, Hardness examination gear, Tensile take a look at equipment

– Area treatment: Blacking, Polishing, Anodize, Painting, Chrome plating, Zinc plating,Nickel plating, Tinting, Electrical power coating, E-coating… and many others

– Used software for specification drawings: Professional/E, Auto CAD, Solidwork, CAXA, UG… and so on

– Additional accessible procedure: Turning, cutting, milling, grinding, drilling, reaming, welding, stamping and threading

(sand casting workshop)

(Evergreen Machinery’s Patents)

What can CZPT Equipment supply, what assignments can you full via us?

Our primary organization in metal goods, and our merchandise assortment primarily covers Metal perform, Aluminum Casting, Expense/Precision casting steel, Sand casting, Forging…and so forth.

These items utilized in Wind energy, Turbine, heavy obligation Truck, Train, Hydraulic Cylinder, Engine, Agriculture products, Lighting, Marine and Mining machinery, Components, CZPT breeding, etc.

(Sand casting workshop)

Evergreen Machinery’s Capability & Capacity:

– Potential: 1>Al die casting: 3000~4000 ton for every year

2>Sand casting: ten thousand ton for each yr

3>Investment casting: 2000 ton for each calendar year

4> Forging: 8000 ton for each 12 months

– Certification: EN15085 & ISO3834 welding certificate

– Machining equipment: CNC, Lathe equipment, Milling device, Drilling equipment, Grinding machine… and many others

– Test tools: Optical Spectrum Analyzer, CMM, Hardness take a look at equipment, Tensile examination equipment

– Area remedy: Powder coating, Anodization, Chrome plating, Portray, Sand blasting, Galvanization

(investment casting workshop)

Evergreen Machinery’s Good quality & Support:

Evergreen Machinery’s good quality philosophy is “No Compromise“.

We have a various customer variety CZPT more than thirty international locations and locations, Germany, United states, Australia & Japan are our main marketplaces. We’re dedicated to serve our customer by providing high quality products and providers. For our original consumers, we supply items and services that fulfill or exceed their anticipations whenever necessary. For our rising marketplace clients, we supply worth-included, affordable items every time attainable.

Welcome to check out CZPT Equipment (the photograph demonstrates the client and our standard supervisor Walt Wang)

| Process Sort | MATERIAL | STHangZhouRD | |

| Sand Casting | Environmentally friendly Sand | Grey Iron, Ductile Iron, Malleable Iron, Brass, Bronze | ISO GB ASTM SAE BS JIS DIN |

| Furan Resin Sand | |||

| Chilly Harden Resin Sand | |||

| Investment casting | H2o galss casting | Stainless Metal, Carbon Steel, Special Alloy Metal Bronze, Brass, Aluminum | |

| Lost wax casting | |||

| Forging | Hot Forging | Stainless Metal, Carbon Metal, Alloy Streel, Brass, Aluminum | |

| Heat Forging | |||

| Chilly Forging | |||

| Machining and other even more processiong | Stamping, cutting, welding, sharpening,sand blasting…… | All metal substance | |

Who We Serve? You are our good quality buyer!

The Programs of Our OEM Custom made Metallic Parts Motor areas, Auto components, Machinery Parts, Rail Prepare elements, Truck Elements,Tractor Components, Construction Equipment, Agriculture Tools,Other industrial fields.

Evergreen Machinery’s FAQ:

Q: Do you make personalized items or finished elements?

A: Yes,all components are not in stock, custom made created in accordance to customer’s drawings or samples! If you have any parts to be made, remember to really feel free to send your drawings/samples to us.

Q: Will my drawing be safe soon after you get it?

A: Yes, we will not launch your style to 3rd celebration except if with your authorization. And we can sign the NDA just before you send the drawing.

Q: What is the MOQ?

A: Typically we do not have a MOQ, but the a lot more, the less costly. Besides, we are pleased to make prototype portion or sample for clientele to guarantee top quality common.

Q: Whether or not some samples can be provided?

A: Yes, just require some sample value, we will return it again when proceed into mass generation. If a molded is required, we will cost the mold price prior to beginning. Then the mold belongs to client.

Q: What is actually your goods selection?

A: OEM & ODM goods selection: Car parts, Truck Components, Motor elements, Agriculture products parts, Prepare areas, Hardware, and many others.

Q: What is actually machining devices do you have?

A: CNC, Lathe machine, Milling device, Drilling device, and so on

Q: Do you have any take a look at gear?

A: Optical Spectrum Analyzer, CMM, Hardness test gear, Tensile take a look at equipment

Q: How to deal with it when they are located to be in bad good quality?

A: Please rest confident that all our items are QC inspected and acknowledged with inspection report just before shipping and usually there will be no non-conformance in scenario of non-conformance, please make contact with us instantly, take some photographs or video clips, we will verify the issues and have them reworked or repaired or replaced at the very first time, the resulting transportation charges will be borne by our company.

|

US $36 / pcs | |

200 pcs (Min. Order) |

###

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Three-Ring |

| Hardness: | Hardened Tooth Surface |

| Installation: | Torque Arm Type |

| Step: | Three-Step |

###

| Samples: |

US$ 36/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| PROCESS TYPE | MATERIAL | STANDARD | |

| Sand Casting | Green Sand | Grey Iron, Ductile Iron, Malleable Iron, Brass, Bronze | ISO GB ASTM SAE BS JIS DIN |

| Furan Resin Sand | |||

| Cold Harden Resin Sand | |||

| Investment casting | Water galss casting | Stainless Steel, Carbon Steel, Special Alloy Steel Bronze, Brass, Aluminum | |

| Lost wax casting | |||

| Forging | Hot Forging | Stainless Steel, Carbon Steel, Alloy Streel, Brass, Aluminum | |

| Warm Forging | |||

| Cold Forging | |||

| Machining and other further processiong | Stamping, cutting, welding, polishing,sand blasting…… | All metal material | |

|

US $36 / pcs | |

200 pcs (Min. Order) |

###

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Three-Ring |

| Hardness: | Hardened Tooth Surface |

| Installation: | Torque Arm Type |

| Step: | Three-Step |

###

| Samples: |

US$ 36/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| PROCESS TYPE | MATERIAL | STANDARD | |

| Sand Casting | Green Sand | Grey Iron, Ductile Iron, Malleable Iron, Brass, Bronze | ISO GB ASTM SAE BS JIS DIN |

| Furan Resin Sand | |||

| Cold Harden Resin Sand | |||

| Investment casting | Water galss casting | Stainless Steel, Carbon Steel, Special Alloy Steel Bronze, Brass, Aluminum | |

| Lost wax casting | |||

| Forging | Hot Forging | Stainless Steel, Carbon Steel, Alloy Streel, Brass, Aluminum | |

| Warm Forging | |||

| Cold Forging | |||

| Machining and other further processiong | Stamping, cutting, welding, polishing,sand blasting…… | All metal material | |

How to Select a Gearbox

When you drive your vehicle, the gearbox provides you with traction and speed. The lower gear provides the most traction, while the higher gear has the most speed. Selecting the right gear for your driving conditions will help you maximize both. The right gearing will vary based on road conditions, load, and speed. Short gearing will accelerate you more quickly, while tall gearing will increase top speed. However, you should understand how to use the gearbox before driving.

Function

The function of the gearbox is to transmit rotational energy to the machine’s drive train. The ratio between input and output torque is the ratio of the torque to the speed of rotation. Gearboxes have many different functions. A gearbox may have multiple functions or one function that is used to drive several other machines. If one gear is not turning, the other will be able to turn the gearbox. This is where the gearbox gets its name.

The pitch-controlled system has an equal number of failure modes as the electrical system, accounting for a large proportion of the longest machine downtime and halt time. The relationship between mechanisms and faults is not easily modeled mathematically. Failure modes of gearboxes are shown in Fig. 3. A gearbox’s true service life is six to eight years. However, a gearbox’s fault detection process must be developed as mature technology is required to reduce the downtime and avoid catastrophic incidents.

A gearbox is a vital piece of machinery. It processes energy produced by an engine to move the machine’s parts. A gearbox’s efficiency depends on how efficiently it transfers energy. The higher the ratio, the more torque is transferred to the wheels. It is a common component of bicycles, cars, and a variety of other devices. Its four major functions include:

In addition to ensuring gearbox reliability, a gearbox’s maintainability should be evaluated in the design phase. Maintainability considerations should be integrated into the gearbox design, such as the type of spare parts available. An appropriate maintenance regime will also determine how often to replace or repair specific parts. A proper maintenance procedure will also ensure that the gearbox is accessible. Whether it is easy to access or difficult to reach, accessibility is essential.

Purpose

A car’s transmission connects the engine to the wheels, allowing a higher-speed crankshaft to provide leverage. High-torque engines are necessary for the vehicle’s starting, acceleration, and meeting road resistance. The gearbox reduces the engine’s speed and provides torque variations at the wheels. The transmission also provides reversing power, making it possible to move the vehicle backwards and forwards.

Gears transmit power from one shaft to another. The size of the gears and number of teeth determine the amount of torque the unit can transmit. A higher gear ratio means more torque, but slower speed. The gearbox’s lever moves the engaging part on the shaft. The lever also slides the gears and synchronizers into place. If the lever slips to the left or right, the engine operates in second gear.

Gearboxes need to be closely monitored to reduce the likelihood of premature failure. Various tests are available to detect defective gear teeth and increase machine reliability. Figure 1.11(a) and (b) show a gearbox with 18 teeth and a 1.5:1 transmission ratio. The input shaft is connected to a sheave and drives a “V” belt. This transmission ratio allows the gearbox to reduce the speed of the motor, while increasing torque and reducing output speed.

When it comes to speed reduction, gear box is the most common method for reducing motor torque. The torque output is directly proportional to the volume of the motor. A small gearbox, for example, can produce as much torque as a large motor with the same output speed. The same holds true for the reverse. There are hybrid drives and in-line gearboxes. Regardless of the type, knowing about the functions of a gearbox will make it easier to choose the right one for your specific application.

Application

When selecting a gearbox, the service factor must be considered. Service factor is the difference between the actual capacity of the gearbox and the value required by the application. Additional requirements for the gearbox may result in premature seal wear or overheating. The service factor should be as low as possible, as it could be the difference between the lifetime of the gearbox and its failure. In some cases, a gearbox’s service factor can be as high as 1.4, which is sufficient for most industrial applications.

China dominates the renewable energy industry, with the largest installed capacity of 1000 gigawatts and more than 2000 terawatt hours of electricity generated each year. The growth in these sectors is expected to increase the demand for gearboxes. For example, in China, wind and hydropower energy production are the major components of wind and solar power plants. The increased installation capacity indicates increased use of gearboxes for these industries. A gearbox that is not suitable for its application will not be functional, which may be detrimental to the production of products in the country.

A gearbox can be mounted in one of four different positions. The first three positions are concentric, parallel, or right angle, and the fourth position is shaft mount. A shaft mount gearbox is typically used in applications where the motor can’t be mounted via a foot. These positions are discussed in more detail below. Choosing the correct gearbox is essential in your business, but remember that a well-designed gearbox will help your bottom line.

The service factor of a gearbox is dependent on the type of load. A high shock load, for example, can cause premature failure of the gear teeth or shaft bearings. In such cases, a higher service factor is required. In other cases, a gearbox that is designed for high shock loads can withstand such loads without deteriorating its performance. Moreover, it will also reduce the cost of maintaining the gearbox over time.

Material

When choosing the material for your gearbox, you must balance the strength, durability, and cost of the design. This article will discuss the different types of materials and their respective applications and power transmission calculations. A variety of alloys are available, each of which offers its own advantages, including improved hardness and wear resistance. The following are some of the common alloys used in gears. The advantage of alloys is their competitive pricing. A gear made from one of these materials is usually stronger than its counterparts.

The carbon content of SPCC prevents the material from hardening like SS. However, thin sheets made from SPCC are often used for gears with lower strength. Because of the low carbon content, SPCC’s surface doesn’t harden as quickly as SS gears do, so soft nitriding is needed to provide hardness. However, if you want a gear that won’t rust, then you should consider SS or FCD.

In addition to cars, gearboxes are also used in the aerospace industry. They are used in space travel and are used in airplane engines. In agriculture, they are used in irrigation, pest and insect control machinery, and plowing machines. They are also used in construction equipment like cranes, bulldozers, and tractors. Gearboxes are also used in the food processing industry, including conveyor systems, kilns, and packaging machinery.

The teeth of the gears in your gearbox are important when it comes to performance. A properly meshing gear will allow the gears to achieve peak performance and withstand torque. Gear teeth are like tiny levers, and effective meshing reduces stress and slippage. A stationary parametric analysis will help you determine the quality of meshing throughout the gearing cycle. This method is often the most accurate way to determine whether your gears are meshing well.

Manufacturing

The global gear market is divided into five key regions, namely, North America, Europe, Asia Pacific, and Latin America. Among these regions, Asia Pacific is expected to generate the largest GDP, owing to rapidly growing energy demand and investments in industrial infrastructure. This region is also home to some of the largest manufacturing bases, and its continuous building of new buildings and homes will support the industry’s growth. In terms of application, gearboxes are used in construction, agricultural machinery, and transportation.

The Industrial Gearbox market is anticipated to expand during the next several years, driven by the rapid growth of the construction industry and business advancements. However, there are several challenges that hamper the growth of the industry. These include the high cost of operations and maintenance of gear units. This report covers the market size of industrial gearboxes globally, as well as their manufacturing technologies. It also includes manufacturer data for the period of 2020-2024. The report also features a discussion of market drivers and restraints.

Global health crisis and decreasing seaborne commerce have moderately adverse effects on the industry. Falling seaborne commerce has created a barrier to investment. The value of international crude oil is expected to cross USD 0 by April 2020, putting an end to new assets development and exploitation. In such a scenario, the global gearbox market will face many challenges. However, the opportunities are huge. So, the market for industrial gearboxes is expected to grow by more than 6% by 2020, thanks to the increasing number of light vehicles sold in the country.

The main shaft of a gearbox, also known as the output shaft, spins at different speeds and transfers torque to an automobile. The output shaft is splined so that a coupler and gear can be connected to it. The counter shaft and primary shaft are supported by bearings, which reduce friction in the spinning element. Another important part of a gearbox is the gears, which vary in tooth count. The number of teeth determines how much torque a gear can transfer. In addition, the gears can glide in any position.

editor by czh 2022-12-19

China Power Steering Gear Box for Hyundai Tucson Tl Tle 2WD 2015- OEM 56500-D3000 gearbox adjustment

Item Description

About us

ZheJiang CZPT Vehicle Components Co., Ltd. is a business specializing in the creation and processing of steering equipment assembly and other products, with a full and scientific top quality administration system. The integrity, toughness and product good quality of ZheJiang CZPT Car Parts Co., Ltd. have been acknowledged by the sector. Welcome friends from all walks of life to visit, CZPT and organization negotiation.

Merchandise Description

electrical power steering equipment box for Hyundai Tucson TL TLE 2WD 2015- OEM 56500-D3000

| product name | WT-1055 steering equipment box |

| brand name | WOTIAN |

| Fitment | Hyundai Tucson TL TLE 2WD |

| Xihu (West Lake) Dis. drive | Left hand push |

| OE number | 56500-D3000 |

| good quality | a hundred% examined |

| warranty | twelve months |

| Packing | neutral packing/customizable |

| Supply Time | inside of 7 organization days |

| Payment | L/C,T/T,Western Union |

one,Are you factory?

Sure,We are specialist manufacturing facility of steering racks.

2. Do you have neutral packing?

Of course, we have neutral packing ,or is dependent on customer’s need.

3. How prolonged instances guarantee of your merchandise?

As common, twelve months

Electronic product, 6 month guarantee.

four. What could you do if client return very good?

Adjust a new 1, or consumer send it again to us and we return funds.

5. How long for supply time right after buy paid out?

As common, all merchandise are in inventory, 3-ten times. If not in inventory, want much more days.

|

US $10-30 / Piece | |

50 Pieces (Min. Order) |

###

| Warranty: | 12 Months |

|---|---|

| Type: | Steering Gears/Shaft |

| Material: | Aluminum Steel Rubber |

| Certification: | ISO |

| Standard: | Standard |

| Condition: | New |

###

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| product name | WT-1055 steering gear box |

| brand | WOTIAN |

| Fitment | Hyundai Tucson TL TLE 2WD |

| Guide drive | Left hand drive |

| OE number | 56500-D3000 |

| quality | 100% tested |

| warranty | 12 months |

| Packing | neutral packing/customizable |

| Delivery Time | within 7 business days |

| Payment | L/C,T/T,Western Union |

|

US $10-30 / Piece | |

50 Pieces (Min. Order) |

###

| Warranty: | 12 Months |

|---|---|

| Type: | Steering Gears/Shaft |

| Material: | Aluminum Steel Rubber |

| Certification: | ISO |

| Standard: | Standard |

| Condition: | New |

###

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| product name | WT-1055 steering gear box |

| brand | WOTIAN |

| Fitment | Hyundai Tucson TL TLE 2WD |

| Guide drive | Left hand drive |

| OE number | 56500-D3000 |

| quality | 100% tested |

| warranty | 12 months |

| Packing | neutral packing/customizable |

| Delivery Time | within 7 business days |

| Payment | L/C,T/T,Western Union |

The Different Types of Gearboxes

There are many different types of gearboxes. Some brands have more than one type. In this article, we’ll discuss the planetary gearbox, the worm reduction gearbox, the shaft mounted gearbox, and the one speed gearbox. This article will also help you determine which type of gearbox is best for your vehicle. And don’t worry if you don’t know the terminology yet. We’ll explain each type in detail so that you know what you’re getting yourself into.

Planetary gearbox

Planetary gears have many advantages. The multiple gears in a planetary gearbox mesh simultaneously during operation. As such, they provide high efficiency and transmit high transmittable torque. These gears are widely used in various industries and are resistant to high shock loads and demanding conditions. CZPT is one of the companies that offer planetary gearboxes. Its products do not require special tools for assembly, and its scalable design minimizes safety stock.

Among the numerous benefits of planetary gearing is its compactness and lightweight. As such, it is suitable for wide applications with space and weight constraints. However, to truly appreciate its benefits, it is necessary to understand its mechanisms. Here are some of the most common details about planetary gearing:

The planetary gearbox has two mounted gears: an input shaft and an output shaft. Each gear has multiple teeth that are attached to a carrier and rotate with the input shaft. The carrier is connected to the output shaft. A planetary gear is mounted on both gears via a carrier. The carrier rotates in order to drive the planetary gear. The sun gear is often the input gear. The other gear is called the outer gear.

Planetary gearboxes are highly customizable. The size, mounting, and housing options vary, as do the reduction ratios and input speeds. Different types can be manufactured for different applications and include options such as electrical or mechanical preload. The final design of a planetary gearbox can be highly customized, based on the specifications of the application. By combining engineering excellence and ongoing innovation, planetary gearboxes provide years of trouble-free operation.

A planetary gearbox can be either an electric motor or a manual one. The latter has more features than the former, and can be used in applications where space is an issue. The primary features of a planetary gearbox include its backlash, torque, and ratio. Secondary features include noise, corrosion resistance, and construction. A planetary gearbox is a highly versatile gearbox that can drive anything from simple machinery to advanced electrical systems.

Worm reduction gearbox

The global worm reduction gearbox market report compiles key insights from the industry to help you improve your business strategy. This report will help you create a comprehensive business document that will enhance your company’s competitive edge. To obtain this report, visit our website now! Read our latest report to find out what you can expect from the global worm reduction gearbox market. Alternatively, request a sample copy for more details. Here is a sneak peek of the report:

Worm gears are made with different thread counts and are usually not matched with the CZPT standard. In general, a single thread worm should be used with a single thread worm. Worm gears have either right or left threads, and their thread count will be different as well. This type of gear is used to reduce the speed of a rotating shaft. The speed reduction ratio will be about 50 percent if the worms have the same thread count as the CZPT gears.

The standard gear set transfers power at the peak load point of a tooth, called the pitchline. The worm gear moves slowly against the wheel’s metal surface. The worm gear is also more complex than the standard gear because the worm is sliding rather than rolling. Worm gears are hard to lubricate. Moreover, the sliding contact between the gear and worm increases the complexity of the gear set. They can be a great solution for applications where noise is a significant factor.

The axial pitch and circular pitch of the worm are equal. The ratio of these two indices determines the speed of transmission. For a worm reduction gearbox to work, the axial pitch and the circular pitch must match. The pitch angle of a worm can either be left-handed or right-handed. The lead of a worm is the distance one thread travels in one revolution. The lead angle is the angle tangent to the thread helix of the cylinder’s pitch. When a worm mesh is reversed, the majority of the mesh will be on the receding arc.

Worm gears generate more heat than their counterparts, so it is important to choose a worm reduction gearbox carefully. You will want to choose the material and amount of lubricating oil carefully. Worm gears are generally made of tin bronze. The paired worms are hardened to HRC45-55. In general, they are durable, lasting up to ten years. But they will wear out – and they wear out – so you may want to consider some other factors.

Shaft-mounted gearbox

Shaft-mounted gearboxes are designed for a variety of mining and quarry applications. Their high reliability and low maintenance make them an excellent choice in these types of applications. Shaft-mounted gearboxes also feature an optional backstop device that prevents the unit from rotating in one direction. This makes them an excellent choice for applications where alignment accuracy is an issue. Here are some of the benefits of using a shaft-mounted gearbox:

Shaft-mounted gearboxes are typically constructed of aluminium, and come in sizes ranging from 050 to 125. They feature a variety of reduction ratios and ensure optimum efficiency in all operating conditions. New S series sizes, 140 and 150, extend the application range of shaft-mounted gearmotors. They are both backed by a two-year warranty. For even greater peace of mind, Shaft-mounted gearboxes are available with a range of warranty options.

The most common applications for a Shaft-mounted gearbox include traction-driven applications where a low-speed shaft is required for operation. They also are suitable for applications without a foundation, where the motor is mounted next to the reducer. To prevent the gear drive from rotating, a torque arm is attached between the motor and the shaft. Small-sized shaft-mounted gear drives are usually made without motor mount kits, which can make them an excellent choice for conveying light loads.

Another important feature of a Shaft-mounted gearbox is its mounting position. The reduced motion through the drive is redirected through the shaft, creating additional forces. These additional forces can affect the performance of the gearbox, causing vibrations and noise. Consequently, it is important to replace worn or damaged belts on a regular basis. Further, shaft-mounted gearboxes can be affected by problems with other components and amplify vibrations.

1 speed gearbox

CZPT Group Components produces one speed gearboxes. These transmissions are produced in the CZPT Group’s Kassel plant. They are compact and robust, and are designed for easy integration. The Bosch Rexroth GD1 one-speed gearbox is easy to install horizontally or vertically. The Plug and Drive system integrates the gearbox with the existing cooling system. There are many other benefits to this gearbox.

With an ID.3 electric drive motor, the maximum torque is delivered at 16,000 rpm. This single-speed transmission offers high power density and excellent noise-reduction, making it ideal for electric vehicles. The e-drive motor is extremely quiet and requires precision manufacturing. The e-drive motor also enables a wide range of driving conditions. It can reverse when needed, and reaches its maximum speed at 16,000.

The single-speed gearbox is a standard feature on most electric vehicles. Some electric vehicles, such as the Porsche Taycan, will be equipped with a two-speed gearbox. This gearbox offers more top speed and range, but it is more complex than a standard single-speed gearbox. CZPT doesn’t need to add complexity to its electric vehicles. After all, a 355 horsepower family wagon is not likely to need a dual-speed gearbox.

In addition to simplifying the transmission, the patent claims also address improvements in structural design. Fig. 5 shows a schematic representation of a transmission 50′, wherein gear sets Z1 and Z4 are exchanged between partial transmissions. This switch matrix also reflects the synchronized gears and lastshelf gears. Hydraulically betatigte Lamellenkupplungen (HBA) also form a last-shelf gear.

Another advantage of the patent claim is that it offers numerous functional freedoms, which is especially valuable in the design of an automobile. One of the patent claims identifies a tosatzlicher middle gear that allows a driver to switch between second and third gears, with a single gearbox. In a conventional one-speed transmission, the tosatzlicher middle gear is attached to the second and first part gearbox. The latter has a second and third gear.

editor by czh 2022-12-01

in La Paz Bolivia (Plurinational State of) sales price shop near me near me shop factory supplier OEM External Tooth Spur Gear 30 Teeth manufacturer best Cost Custom Cheap wholesaler

At any time-Electrical power Group CO., LTD. IS Expert IN Producing ALL Types OF MECHANICAL TRANSMISSION AND HYDRAULIC TRANSMISSION LIKE: PLANETARY GEARBOXES, WORM REDUCERS, IN-LINE HELICAL Equipment Pace REDUCERS, PARALLEL SHAFT HELICAL Gear REDUCERS, HELICAL BEVEL REDUCERS, HELICAL WORM Equipment REDUCERS, AGRICULTURAL GEARBOXES, TRACTOR GEARBOXES, Vehicle GEARBOXES, PTO Push SHAFTS, Special REDUCER & Associated Gear Components AND OTHER Connected Products, SPROCKETS, HYDRAULIC System, VACCUM PUMPS, FLUID COUPLING, Gear RACKS, CHAINS, TIMING PULLEYS, UDL Velocity VARIATORS, V PULLEYS, HYDRAULIC CYLINDER, Gear PUMPS, SCREW AIR COMPRESSORS, SHAFT COLLARS Reduced BACKLASH WORM REDUCERS AND SO ON. Sophisticated thermo therapy gear, this kind of as community warmth therapy oven, multi-use thermo treatment oven, and so on. a specialized provider of a complete assortment of chains, sprockets, gears, equipment racks, V-belts, couplings and reducers.

Q:What`s the MOQ of your goods?

A:1 established,we can also deal with the sample buy. and the massive-amount.

Q:How could i know if the solution suited for my EPTT?

A:Our product sales will speak to with you to make confident the particular dimension,knowledge and other EPTTant specifics of your aimed merchandise.We make sure all the goods in shape for your EPTT.

Q:I want to discover a new provider for merchandise,can you?

A:Sure,we can give the EPTT day provider for your consulting,we goal at currently being your most EPTTant provider.

Q:What`s the payment conditions of the purchase?

A:As your prerequisite,we can take a number of sorts of payment conditions.

in Bokaro Steel City India sales price shop near me near me shop factory supplier OEM Manufacturer High Hardness Nylon Spur Gear manufacturer best Cost Custom Cheap wholesaler

we offer chromed bar and tubes for hydualic and pheumatic cylinders. The group has taken component in the creating and revising of ISO/TC100 worldwide chain common several years in good results and hosted the 16th ISO/TC100 International yearly assembly in 2004. we supply one-cease resolution for the obtain of mechanical electrical power transmission products in China.

Organization INTRODUCTION

HangEPT EPT EPT EPTT EPTT, Ltd. founded in 2001 , EPTT is found in the EPTT XiHu (West EPT) Dis.Hu (West EPT) Dis.ent metropolis — HangEPT. Our organization has been engaged in creating EPT engineering components, OEM/ODM spare components and EPTT components for a lot of years, incXiHu (West EPT) Dis.Hu (West EPT) Dis. sand casting areas and expenditure casting spare components, forging components, sheet steel stamping spare parts, EPTTd elements and plastic areas, which are commonly used in petrochemical, vehicle, chemical, environmental safety , EPTTry, building, EPT, aerospace, marine EPT and other EPTT.

PE/PVC/Abdominal muscles/PU/EPTDM/NYLON/SILICONE EPTT INJECTION OR VACUUM FORMING EPT SPARE Elements

Model NO.:As per consumer required

EPT:NBR/FKM/Viton/EPT/HNBR/EPTDM/PP/PU/PVC/Abs/NYLON and so on

Application:EPTTry, EPTT Element, EPT Merchandise, EPT, EPTT EPTT Cross-Section Condition:EPTT

Dimensions:EPTT

EPTT:Black,Pink,Gray,Brown,Espresso and so forth

Workmanship:Plastic Injection EPTing/Vacumm Forming/Blow Molding

Area:EPT, Matt Finish, Shiny, as You Needs

Functioning Temperature:-40~230 Celsius Degree

OEM/ODM:EPTT

Performance:EPT Strain

EPTT-Helpful:Non-Tonix Mould EPT EPT

Perform:Oil Prevention EPT Water Avoidance Sealin

EPTmark: NBR/FKM/Viton/EPT/HNBR/EPTDM/PP/PU/PVC/Abs/NYLON

Specification:ISO9001: 2015 TS16949 SGS

Company EPTS

THE EPTAGE AND Shipment

Consumers

in Kota India sales price shop near me near me shop factory supplier OEM Customized Auto Parts Gear Ring manufacturer best Cost Custom Cheap wholesaler

Wonderful attention has been paid out on environmental protection and power preserving. Support & Top quality controlWe offer thorough drawings and supply each time required. Our products are applied in several fields. OEM EPTT automobile components EPT ring

1. Description

| No. | Merchandise | Description |

| 1 | Name | Inside EPT Ring |

| two | Measurement | EPT can be EPT. |

| three | Manufacture StXiHu (West EPT) Dis.Hu (West EPT) Dis.rd | five-eight Grade ISO1328-1997. |