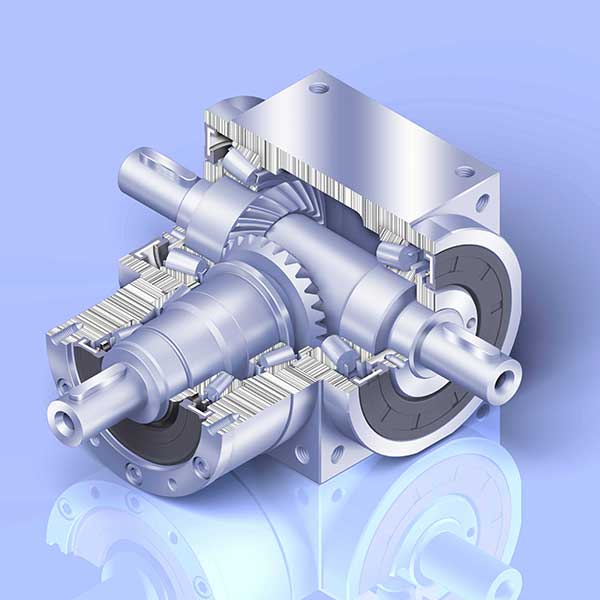

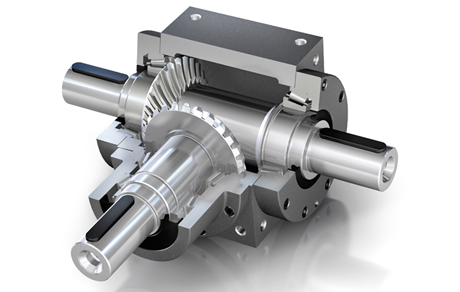

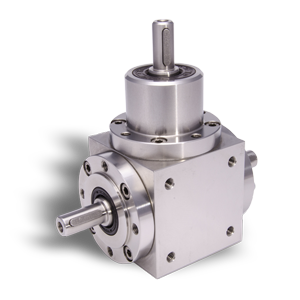

Product Description

MW High Quality Agricultural Industrial Aluminium Small Planetary NMRV Mower Rotary Cutter Spiral Bevel Swing Variable Speed Differential Reducer Tiller Gearbox

Our Gearbox has many items for your choosing and we can produce as per your drawing or sample to meet your special request

1. Large output torque

2. Safe, reliable, economical and durable

3. Stable transmission, quiet operation

4. High carrying ability

5. High modularization design, may equip with various outer power input conveniently. Same machine type may equip with various power motor. It is easy to realize the combination and junction between every machine type

6. Transmission ratio: Fine division, wide scope. The combined machine type may form very large transmission ratio, i. E. Output very low rotary speed.

7. Form of installation: The position to be installed is not limited.

8. High strength, compact the box body of high strength cast iron, gear and gear shaft adapts the gas carbonization, quenching and fine grinding process, therefore the bearing capacity of unit volume is high.

9. Long life: Under the condition of correct type chosen(including choosing suitable operation parament ) normal operation and maintenance, the life if main parts speed reducer(except wearing parts)should not be less than 20000 hours. The wearing parts include lubricating oil, oil seal and bearing.

10. Low noise: Because main parts of speed reducer are processed, and tested critically, therefore the noise of speed reducer is low.

11.Our gear box have reached the advance international level, can replace the same kind of products imported.

HangZhou CHINAMFG Industry Co., Ltd. is a specialized supplier of a full range of chains, sprockets, gears, gear racks, gearbox, v belt pulley, timing pulley, V-belts, couplings, machined parts and so on.

Due to our CHINAMFG in offering best service to our clients, understanding of your needs and overriding sense of responsibility toward filling ordering requirements, we have obtained the trust of buyers worldwide. Having accumulated precious experience in cooperating with foreign customers, our products are selling well in the American, European, South American and Asian markets.Our products are manufactured by modern computerized machinery and equipment. Meanwhile, our products are manufactured according to high quality standards, and complying with the international advanced standard criteria.

With many years’ experience in this line, we will be trusted by our advantages in competitive price, one-time delivery, prompt response, on-hand engineering support and good after-sales services.

Additionally, all our production procedures are in compliance with ISO9001 standards. We also can design and make non-standard products to meet customers’ special requirements. Quality and credit are the bases that make a corporation alive. We will provide best services and high quality products with all sincerity. If you need any information or samples, please contact us and you will have our soon reply.

|

Shipping Cost:

Estimated freight per unit. |

To be negotiated |

|---|

| Application: | Motor, Machinery, Marine, Agricultural Machinery |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Coaxial |

| Customization: |

Available

| Customized Request |

|---|

Role of Spiral Bevel Gearboxes in Automotive and Aerospace Industries

Automotive Industry: Spiral bevel gearboxes have significant roles in the automotive sector:

a. Differential Systems: In vehicles, spiral bevel gearboxes are a key component of the differential system. They enable the distribution of torque between the left and right wheels while allowing them to rotate at different speeds during turns. This improves stability, traction, and maneuverability.

b. Transmissions: Spiral bevel gearboxes are also used in some manual transmissions. They help in transferring power and torque efficiently between the engine and the wheels, contributing to smooth gear shifting and overall vehicle performance.

c. Power Steering: In power steering systems, spiral bevel gearboxes assist in translating the rotational movement of the steering wheel into lateral movement of the wheels. This makes steering easier for the driver.

Aerospace Industry: In the aerospace sector, spiral bevel gearboxes have crucial roles:

a. Landing Gear Systems: Aircraft landing gear systems use spiral bevel gearboxes to control the extension and retraction of landing gear during takeoff and landing. These gearboxes ensure precise and synchronized movement, contributing to safe landings and takeoffs.

b. Flight Control Systems: Spiral bevel gearboxes are used in flight control systems to translate pilot inputs into controlled movements of control surfaces such as ailerons, elevators, and rudders. They ensure accurate and responsive control of the aircraft.

c. Engine Accessory Drives: Some aircraft engines utilize spiral bevel gearboxes to transfer power from the engine to various accessories such as generators, hydraulic pumps, and compressors. These gearboxes ensure efficient power distribution and operation of essential systems.

Spiral bevel gearboxes are crucial in both the automotive and aerospace industries, contributing to vehicle performance, safety, and overall functionality.

Disadvantages and Limitations of Spiral Bevel Gear Systems

Spiral bevel gear systems offer many advantages, but they also come with some disadvantages and limitations:

- Complex Manufacturing: The manufacturing process for spiral bevel gears is more intricate and time-consuming than for some other gear types, leading to potentially higher costs.

- Higher Noise Levels: While spiral bevel gears are designed to minimize noise, they can still produce more noise than other gear types, particularly at high speeds.

- Increased Friction and Heat: The meshing action of spiral bevel gears generates more friction and heat compared to some other gear systems, which may require more robust lubrication and cooling mechanisms.

- Less Suitable for High-Speed Applications: While spiral bevel gears can operate at high speeds, their design may make them less suitable for extremely high-speed applications where other gear types, such as helical gears, may be preferred.

- Complex Maintenance: Disassembling and assembling spiral bevel gearboxes can be more complex and time-consuming due to the precision required for gear meshing and alignment.

- Specific Installation Requirements: Spiral bevel gears require precise alignment during installation to ensure proper meshing and performance, which can add complexity to the assembly process.

- Space Limitations: The configuration of spiral bevel gears requires more axial space compared to some other gear types, which may be a limitation in applications with restricted space.

Despite these disadvantages, spiral bevel gear systems remain a valuable choice in various industrial applications where their benefits outweigh the limitations.

Industries Using Spiral Bevel Gearboxes

Spiral bevel gearboxes find applications across various industries where precise power transmission, high torque capacity, and efficient motion transfer are essential. Some of the industries that commonly utilize spiral bevel gearboxes include:

- Automotive: Spiral bevel gears are used in automotive differentials, axles, and steering systems to transmit power efficiently and handle changing loads and directions.

- Aerospace: Aerospace applications require reliable and lightweight power transmission, making spiral bevel gears suitable for aircraft engines, landing gear, and control systems.

- Heavy Machinery: Industries like construction, mining, and agriculture use spiral bevel gearboxes in equipment such as excavators, bulldozers, tractors, and loaders.

- Manufacturing: Spiral bevel gears play a role in industrial machinery, conveyors, robotics, and machine tools, ensuring precise motion and power distribution.

- Marine: Marine propulsion systems and steering mechanisms benefit from the robustness and efficiency of spiral bevel gears.

- Energy: Spiral bevel gearboxes are used in power generation equipment, including wind turbines, hydroelectric generators, and gas turbines.

- Railways: Trains rely on spiral bevel gears in their transmission systems and bogie assemblies to deliver power and maintain stability.

The versatility, durability, and reliable performance of spiral bevel gearboxes make them a valuable component in various industrial sectors.

editor by CX 2023-09-15