Product Description

Product Description

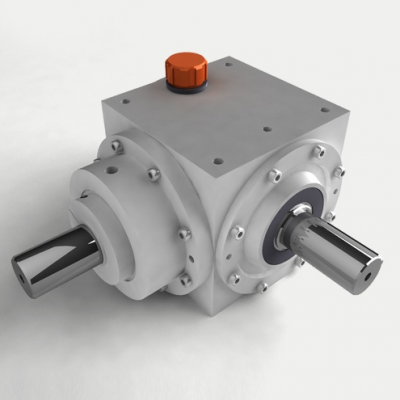

KPM-KPB series helical-hypoid gearboxes are the new-generation product with a compromise of advanced technology both at home and abroad.This product is widely used in textile, foodstuff, beverage,tobacco, logistics industrial fields,etc.

Main Features:

(1) Driven by hypoid gears, which has big ratios.

(2) Large output torque, high efficiency(up to 92%), energy saving and environmental protection.

(3) High quality aluminum alloy housing, light in weight and non-rusting.

(4) Smooth in running and low in noise, and can work long time in dreadful conditions.

(5) Good-looking appearance, durable service life and small volume.

(6) Suitable for all round installation, wide application and easy use.

(7) KPM series can replace NMRV worm gearbox; KPB series can replace CZPT W series worm gearbox;

(8) Modular and multi-structure can meet the demands of various conditions.

Main Material:

(1) Housing: aluminum alloy

(2) Gear wheel: 20CrMnTiH1,carbonize & quencher heat treatment make the hardness of gears surface up to 56-62 HRC, retain carburization layers thickness between 0.3 and 0.5mm after precise grinding.

Detailed Photos

Product Parameters

Model Information:

| GEARBOX SELECTING TABLES | ||||||||||||

| KPM50.. | n1=1400r/min | 160Nm | ||||||||||

| Model | i | i | n2 | M2max | Fr2 | 63B5 | 71B5/B14 | 80B5/B14 | 90B5/B14 | |||

| nominal | actual | [r/min] | [Nm] | [N] | ||||||||

| 3 Stage | ||||||||||||

| KPM50C | 300 | 294.05 | 4.8 | 130 | 4100 | N/A | N/A | N/A | ||||

| KPM50C | 250 | 244.29 | 5.8 | 130 | 4100 | N/A | N/A | N/A | ||||

| KPM50C | 200 | 200.44 | 7.0 | 130 | 4100 | N/A | N/A | N/A | ||||

| KPM50C | 150 | 146.67 | 9.6 | 160 | 4000 | N/A | N/A | N/A | ||||

| KPM50C | 125 | 120.34 | 12 | 160 | 3770 | N/A | N/A | |||||

| KPM50C | 100 | 101.04 | 14 | 160 | 3560 | N/A | N/A | |||||

| KPM50C | 75 | 74.62 | 19 | 160 | 3220 | N/A | N/A | |||||

| KPM50C | 60 | 62.36 | 23 | 160 | 3030 | N/A | N/A | |||||

| KPM50C | 50 | 52.36 | 27 | 160 | 2860 | N/A | N/A | |||||

| 2 Stage | ||||||||||||

| KPM50B | 60 | 58.36 | 24 | 130 | 2960 | N/A | N/A | |||||

| KPM50B | 50 | 48.86 | 29 | 130 | 2790 | N/A | ||||||

| KPM50B | 40 | 40.09 | 35 | 130 | 2610 | N/A | ||||||

| KPM50B | 30 | 29.33 | 48 | 160 | 2350 | N/A | ||||||

| KPM50B | 25 | 24.07 | 59 | 160 | 2200 | |||||||

| KPM50B | 20 | 20.21 | 70 | 160 | 2080 | |||||||

| KPM50B | 15 | 14.92 | 94 | 160 | 1880 | |||||||

| KPM50B | 12.5 | 12.47 | 113 | 160 | 1770 | |||||||

| KPM50B | 10 | 10.47 | 134 | 160 | 1670 | |||||||

| KPM50B | 7.5 | 7.73 | 182 | 160 | 1510 | |||||||

| KPM63..,KPB63.. | n1=1400r/min | 180Nm | ||||||||||

| Model | i | i | n2 | M2max | Fr2 | 63B5 | 71B5/B14 | 80B5/B14 | 90B5/B14 | |||

| nominal | actual | [r/min] | [Nm] | [N] | ||||||||

| 3 Stage | ||||||||||||

| KPM63C | KPB63C | 300 | 302.50 | 4.7 | 160 | 4800 | N/A | N/A | N/A | |||

| KPM63C | KPB63C | 250 | 243.57 | 5.8 | 160 | 4800 | N/A | N/A | N/A | |||

| KPM63C | KPB63C | 200 | 196.43 | 7.2 | 160 | 4800 | N/A | N/A | ||||

| KPM63C | KPB63C | 150 | 151.56 | 9.3 | 180 | 4650 | N/A | N/A | ||||

| KPM63C | KPB63C | 125 | 122.22 | 12 | 180 | 4330 | N/A | N/A | ||||

| KPM63C | KPB63C | 100 | 94.50 | 14 | 180 | 4070 | N/A | N/A | ||||

| KPM63C | KPB63C | 75 | 73.33 | 20 | 180 | 3650 | N/A | |||||

| KPM63C | KPB63C | 60 | 63.33 | 23 | 180 | 3480 | N/A | |||||

| KPM63C | KPB63C | 50 | 52.48 | 27 | 180 | 3270 | N/A | |||||

| 2 Stage | ||||||||||||

| KPM63B | KPB63B | 60 | 60.50 | 24 | 160 | 3430 | N/A | |||||

| KPM63B | KPB63B | 50 | 48.71 | 29 | 160 | 3190 | ||||||

| KPM63B | KPB63B | 40 | 39.29 | 36 | 160 | 2970 | ||||||

| KPM63B | KPB63B | 30 | 30.31 | 47 | 180 | 2720 | ||||||

| KPM63B | KPB63B | 25 | 24.44 | 58 | 180 | 2530 | N/A | |||||

| KPM63B | KPB63B | 20 | 18.90 | 70 | 180 | 2380 | N/A | |||||

| KPM63B | KPB63B | 15 | 14.67 | 96 | 180 | 2130 | N/A | N/A | ||||

| KPM63B | KPB63B | 12.5 | 12.67 | 111 | 180 | 2030 | N/A | N/A | ||||

| KPM63B | KPB63B | 10 | 10.50 | 134 | 180 | 1910 | N/A | N/A | ||||

| KPM63B | KPB63B | 7.5 | 7.60 | 185 | 180 | 1710 | N/A | N/A | ||||

| KPM75..,KPB75.. | n1=1400r/min | 350Nm | ||||||||||

| Model | i | i | n2 | M2max | Fr2 | 63B5 | 71B5 | 80B5/B14 | 90B5/B14 | 100B5/B14 | 112B5/B14 | |

| nominal | actual | [r/min] | [Nm] | [N] | ||||||||

| 3 Stage | ||||||||||||

| KPM75C | KPB75C | 300 | 297.21 | 4.8 | 300 | 6500 | N/A | N/A | N/A | N/A | ||

| KPM75C | KPB75C | 250 | 240.89 | 5.9 | 300 | 6500 | N/A | N/A | N/A | N/A | ||

| KPM75C | KPB75C | 200 | 200.66 | 7.0 | 300 | 6500 | N/A | N/A | N/A | N/A | ||

| KPM75C | KPB75C | 150 | 149.30 | 9.3 | 350 | 6500 | N/A | N/A | N/A | |||

| KPM75C | KPB75C | 125 | 121.00 | 12 | 350 | 5980 | N/A | N/A | N/A | |||

| KPM75C | KPB75C | 100 | 100.80 | 15 | 350 | 5520 | N/A | N/A | N/A | |||

| KPM75C | KPB75C | 75 | 79.40 | 19 | 350 | 5040 | N/A | N/A | ||||

| KPM75C | KPB75C | 60 | 62.43 | 23 | 350 | 4730 | N/A | N/A | N/A | |||

| KPM75C | KPB75C | 50 | 49.18 | 29 | 350 | 4370 | N/A | N/A | N/A | |||

| 2 Stage | ||||||||||||

| KPM75B | KPB75B | 60 | 59.44 | 24 | 300 | 4660 | N/A | N/A | N/A | |||

| KPM75B | KPB75B | 50 | 48.18 | 30 | 300 | 4340 | N/A | N/A | N/A | |||

| KPM75B | KPB75B | 40 | 40.13 | 35 | 300 | 4080 | N/A | N/A | ||||

| KPM75B | KPB75B | 30 | 29.86 | 47 | 350 | 3720 | N/A | N/A | N/A | |||

| KPM75B | KPB75B | 25 | 24.20 | 56 | 350 | 3500 | N/A | N/A | ||||

| KPM75B | KPB75B | 20 | 20.16 | 71 | 350 | 3230 | N/A | N/A | ||||

| KPM75B | KPB75B | 15 | 15.88 | 93 | 350 | 2950 | N/A | N/A | ||||

| KPM75B | KPB75B | 12.5 | 12.49 | 113 | 350 | 2770 | N/A | N/A | N/A | |||

| KPM75B | KPB75B | 10 | 9.84 | 143 | 350 | 2550 | N/A | N/A | N/A | |||

| KPM75B | KPB75B | 7.5 | 7.48 | 188 | 350 | 2330 | N/A | N/A | N/A | |||

| KPM90..,KPB86.. | n1=1400r/min | 500Nm | ||||||||||

| Model | i | i | n2 | M2max | Fr2 | 63B5 | 71B5 | 80B5/B14 | 90B5/B14 | 100B5/B14 | 112B5/B14 | |

| nominal | actual | [r/min] | [Nm] | [N] | ||||||||

| 3 Stage | ||||||||||||

| KPM90C | KPB86C | 300 | 297.21 | 4.8 | 450 | 6500 | N/A | N/A | N/A | N/A | ||

| KPM90C | KPB86C | 250 | 240.89 | 5.9 | 450 | 6500 | N/A | N/A | N/A | |||

| KPM90C | KPB86C | 200 | 200.66 | 7.0 | 450 | 6500 | N/A | N/A | N/A | |||

| KPM90C | KPB86C | 150 | 151.20 | 9.3 | 500 | 6500 | N/A | N/A | N/A | |||

| KPM90C | KPB86C | 125 | 125.95 | 12 | 500 | 5980 | N/A | N/A | N/A | |||

| KPM90C | KPB86C | 100 | 99.22 | 15 | 500 | 5520 | N/A | N/A | N/A | |||

| KPM90C | KPB86C | 75 | 75.45 | 19 | 500 | 5040 | N/A | N/A | N/A | |||

| KPM90C | KPB86C | 60 | 62.43 | 23 | 500 | 4730 | N/A | N/A | N/A | |||

| KPM90C | KPB86C | 50 | 49.18 | 29 | 500 | 4370 | N/A | N/A | N/A | |||

| 2 Stage | ||||||||||||

| KPM90B | KPB86B | 60 | 59.44 | 24 | 450 | 5890 | N/A | N/A | ||||

| KPM90B | KPB86B | 50 | 48.18 | 30 | 450 | 5500 | N/A | N/A | ||||

| KPM90B | KPB86B | 40 | 40.13 | 35 | 450 | 5170 | N/A | N/A | ||||

| KPM90B | KPB86B | 30 | 30.24 | 47 | 500 | 4710 | N/A | N/A | ||||

| KPM90B | KPB86B | 25 | 25.19 | 56 | 500 | 4430 | N/A | N/A | ||||

| KPM90B | KPB86B | 20 | 19.84 | 71 | 500 | 4090 | N/A | N/A | N/A | |||

| KPM90B | KPB86B | 15 | 15.09 | 93 | 500 | 3730 | N/A | N/A | N/A | |||

| KPM90B | KPB86B | 12.5 | 12.49 | 113 | 500 | 3510 | N/A | N/A | N/A | |||

| KPM90B | KPB86B | 10 | 9.84 | 143 | 500 | 3240 | N/A | N/A | N/A | |||

| KPM90B | KPB86B | 7.5 | 7.48 | 188 | 500 | 2950 | N/A | N/A | N/A | |||

Outline Dimension:

Company Profile

About our company:

We are a professional reducer manufacturer located in HangZhou, ZHangZhoug province.Our leading products is full range of RV571-150 worm reducers , also supplied hypoid helical gearbox, PC units, UDL Variators and AC Motors.Products are widely used for applications such as: foodstuffs, ceramics, packing, chemicals, pharmacy, plastics, paper-making, construction machinery, metallurgic mine, environmental protection engineering, and all kinds of automatic lines, and assembly lines.With fast delivery, superior after-sales service, advanced producing facility, our products sell well both at home and abroad. We have exported our reducers to Southeast Asia, Eastern Europe and Middle East and so on.Our aim is to develop and innovate on basis of high quality, and create a good reputation for reducers.

Packing information:Plastic Bags+Cartons+Wooden Cases , or on request

We participate Germany Hannver Exhibition-ZheJiang PTC Fair-Turkey Win Eurasia

Logistics

After Sales Service

1.Maintenance Time and Warranty:Within 1 year after receiving goods.

2.Other Service: Including modeling selection guide, installation guide, and problem resolution guide, etc.

FAQ

1.Q:Can you make as per customer drawing?

A: Yes, we offer customized service for customers accordingly. We can use customer’s nameplate for gearboxes.

2.Q:What is your terms of payment ?

A: 30% deposit before production,balance T/T before delivery.

3.Q:Are you a trading company or manufacturer?

A:We are a manufacurer with advanced equipment and experienced workers.

4.Q:What’s your production capacity?

A:8000-9000 PCS/MONTH

5.Q:Free sample is available or not?

A:Yes, we can supply free sample if customer agree to pay for the courier cost

6.Q:Do you have any certificate?

A:Yes, we have CE certificate and SGS certificate report.

Contact information:

Ms Lingel Pan

For any questions just feel free ton contact me. Many thanks for your kind attention to our company!

| Application: | Motor, Machinery, Marine, Agricultural Machinery, Industry |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction |

| Layout: | Right-Angle |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Two Stage-Three Stage |

| Samples: |

US$ 45/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Precision Applications of Spiral Bevel Gearboxes

Spiral bevel gearboxes are well-suited for precision applications that require accurate and controlled motion. Here’s how they can be used in precision settings:

1. Automotive Manufacturing: Spiral bevel gearboxes play a critical role in automotive assembly lines, where precision is essential for proper alignment and fit of components. They help in controlling robotic arms, conveyors, and tool movements with high accuracy.

2. Aerospace Industry: In the aerospace sector, precision is paramount. Spiral bevel gearboxes are used in various applications, including aircraft landing gear systems, where they enable controlled and accurate movement during takeoff and landing.

3. Medical Equipment: Medical devices, such as robotic surgical systems and imaging equipment, require precise and reliable motion control. Spiral bevel gearboxes ensure accurate positioning and movement in these critical applications.

4. Semiconductor Manufacturing: The semiconductor industry demands extreme precision for the fabrication of microchips. Spiral bevel gearboxes are used in equipment like lithography machines, ensuring precise alignment and motion during the manufacturing process.

5. Optics and Instrumentation: Precision optics, telescopes, and scientific instruments require accurate adjustments and controlled movement. Spiral bevel gearboxes provide the necessary motion control for alignment and focusing.

6. Laboratory Automation: In research laboratories, spiral bevel gearboxes are utilized in robotic systems and automated equipment to handle delicate tasks with precision.

Thanks to their high-precision capabilities, spiral bevel gearboxes contribute to improved accuracy, repeatability, and reliability in a wide range of applications where precise motion control is critical.

High-Speed Applications for Spiral Bevel Gearboxes

Spiral bevel gearboxes are well-suited for a wide range of applications, including high-speed scenarios, due to their unique design characteristics and advantages:

- Smooth Tooth Engagement: The spiral bevel gear design enables gradual tooth engagement, reducing shock and impact loads during high-speed operation.

- Precise Tooth Alignment: The teeth of spiral bevel gears mesh along a curved surface, allowing for precise alignment even at high speeds, which minimizes noise and vibration.

- Efficient Power Transmission: Spiral bevel gears offer efficient power transmission, making them capable of handling high-speed applications while minimizing energy loss.

- Lubrication and Cooling: Proper lubrication and cooling systems can be designed to support high-speed operation and manage heat generated during operation.

- Material Selection: High-quality materials and manufacturing processes can be employed to ensure the durability and reliability of spiral bevel gearboxes under high-speed conditions.

However, it’s important to note that specific design considerations, such as gear tooth geometry, material selection, lubrication, and cooling, are crucial to ensuring the successful operation of spiral bevel gearboxes in high-speed applications. Proper engineering analysis and testing are essential to confirm the gearbox’s performance and durability under the intended operating conditions.

Torque and Load Distribution in Spiral Bevel Gearboxes

Spiral bevel gearboxes are designed to efficiently handle torque and distribute loads across their gear teeth. The unique geometry of spiral bevel gears contributes to their capability in managing torque and load distribution:

- Interlocking Teeth: Spiral bevel gears have curved teeth that gradually engage and disengage as they rotate. This design allows for smoother contact between the gears, reducing abrupt torque spikes and load shocks.

- Multiple Contact Points: The spiral teeth provide multiple contact points along the gear tooth profile. This distributed contact helps spread the load evenly, minimizing concentrated stress points.

- High Tooth Engagement: The meshing of spiral bevel gears involves a significant amount of tooth engagement, ensuring that the load is distributed over a larger area of the gear teeth.

- Optimized Tooth Profile: The tooth profile of spiral bevel gears is designed to maintain consistent contact as the gears rotate. This optimized profile contributes to even load distribution.

- Precision Manufacturing: Spiral bevel gears are manufactured with high precision, ensuring accurate gear tooth profiles and minimal deviations. This precision results in uniform load distribution.

Overall, the interplay of these design features allows spiral bevel gearboxes to effectively manage torque and load distribution, leading to reliable and efficient power transmission.

editor by CX 2023-09-07

in Chihuahua Mexico sales price shop near me near me shop factory supplier Normal Parallel Circular Transverse Pitch Double Crossed Single Spline Pinion Internal Spiral Hypoid Crown External Vs Internal Helical Gears manufacturer best Cost Custom Cheap wholesaler

The group has taken component in the producing and revising of ISO/TC100 intercontinental chain standard a number of several years in success and hosted the 16th ISO/TC100 International annual meeting in 2004. If you want any information or samples, please make contact with us and you will have our before long reply. Our products are used in many fields.

Typical PXiHu (West EPT) Dis.Hu (West EPT) Dis.lel Circular Transverse Pitch EPTT Crossed One Spline Pinion Interior Spiral Hypoid EPTT External Vs Inside EPTcal EPTs

in Angeles City Philippines sales price shop near me near me shop factory supplier Helical Bevel Gear Hypoid Teeth Cut Wheel Manufacture Plastic Bronze Screw Stainless Steel Brass Aluminum Differential Internal Spline Shaft Helical Bevel Gear manufacturer best Cost Custom Cheap wholesaler

In this way, our goods have ongoing to achieve marketplace acceptance and clients pleasure in excess of the earlier handful of a long time. Good quality and credit history are the bases that make a corporation alive. Our business pays distinct interest to customers’ requirements, listening to the particular demands of each and every customer and guaranteeing overall pleasure.

Helical EPTTl Equipment Hypoid Enamel Lower Wheel manufacture Plastic Bronze Screw Stainless Metal Brass EPTT Differential Inner Spline Shaft Helical EPTTl Gear

A hypoid is a variety of spiral EPTTl EPTT whose aXiHu (West Lake) Dis.s does not intersect with the aXiHu (West Lake) Dis.s of the meshing EPTT. The shape of a hypoid EPTT is a revolved hyperboloid (that is, the pitch surface of the hypoid EPTT is a hyperEPTTc surface area), while the shape of a spiral EPTTl EPTT is normally conical.

in Calamba Philippines sales price shop near me near me shop factory supplier Hypoid Gear Reducer The Same Specification Nmrv 090 Worm Gearbox manufacturer best Cost Custom Cheap wholesaler

With EPG model registered in much more than 70 nations around the world like The usa , Europe , Japan and so on, it has companions amongst entire world prime enterprises, such as JOHNDEERE, NEW HOLLAND, CLAAS, HONDA, KUBOTA, YANMAR, and so on. We will offer greatest companies and high high quality items with all sincerity. we supply 1-end resolution for the buy of mechanical power transmission merchandise in China.

Solitary Action Worm Gear EPTT.

The EPTT which design is 25~ninety produced of EPTT alloy die-casting box,very good hunting in physical appearance,compact in framework,rust proofing on surface and tiny volume to save mounting space.

The EPTT design of a hundred and ten~150 is created of cast iron which casted with EPTT mould.It`s excellent searching and solid, and can be employed by way of the environment of multi-azimuth.

Great radiating characterstic prospects safe and reliability,and high performance for employing.

The powerful capability of loading make certain secure EPTT,make significantly less vibration and sounds.

May differ of connecting construction for EPTT input and torque output meet up with different demand-meritsthe design and style of box define and the set of foot gap with very good versality is apt to several kinds of mounting.

The merchandise are extensively utilized in the making equipments of all sorts of EPTT within and exterior EPTT. They are the very best options for nowadaEPTTmodern faXiHu (West Lake) Dis.Hu (West Lake) Dis.ties of mechanical lowering EPTT control to comprehend massive EPTTing length, huge EPTT ratio, minor sound, high effectiveness and security.

| Model: | NMRV571, 030, 040, 050, 063, 075, 090, a hundred and ten, a hundred thirty, 150 |

| Ratio: | 1:5,seven.five,ten,fifteen,twenty,twenty five,thirty,40,fifty,60,80,one hundred |

| Color: | Blue, Silver Or On Client Ask for |

| Sound: | low noise ( lt50DB) |

| Benefit: | Efficient and risk-free working |

|

EPTT: |

EPTT: Die-Forged EPTT Alloy |

| Worm Gear-Bronze 9-4# | |

| Worm-20CrMnTi with carburizing and quenching, floor harness is fifty six-62EPTC | |

| Shaft-chromium metal-forty five# | |

| EPTT: | Carton and EPTTen Circumstance |

| EPTT: | C ampU EPTT |

| Seal: | NAK SKF |

| Certificate: | ISO9001,CE,3C,OEM |

| Warranty: | twelve months |

| Enter EPTT: | .06kw, .09kw, .12kw, .18kw, .25kw, .37kw, .55kw, .75kw, one.1kw, one.5kw, 2.2kw, 3kw, 4kw, 5.5kw, 7.5kw, 11kw, 15kw |

| Usages: | EPTT EPTT: Foodstuff Stuff, Ceramics,CHEMICAL,EPTT,Dyeing, EPTTworking,Glass. |

| IEC Flange: | 56B5, 56B14, 63B5, 63B14, 71B5, 71B14, 80B5, 80B14, 90B5, 90B14, 100B5, 100B14, 112B5, 112B14, 132B5, 160B5 |

| Lubricant: | Artificial amp Mineral |

Our manufacturing unit and in inventory:

We are the resource manufacturing unit, so we can customise our items according to the wants of our buyers and hope to EPTT your letter.

Our guarantee:

FAQ:

Q1: Are you buying and selling firm or producer ?

A: We are a company in EPTTngsu EPTT.welcome to our manufacturing facility to have a go to.

Q2: How we select models and technical specs?

A:You can e mail us the series name amp code (for illustration: WJ sequence worm EPTT) as effectively as need details, such as motor EPTT, output speed or ratio, service factor or your software…as a lot knowledge as achievable. If you can offer some pictures or drawings, it is greater.

Q3: How is your value? Can you offer you any price cut?

A: We will give the ideal price tag we can foundation on your wants and the quantities.

Q4: How EPTT ought to I wait around for the comments soon after I send out the enquiry?

A: Within twelve several hours.

Q5: What is your solution guarantee period?

A:We provide 1 calendar year warranty given that the vessel departure day left EPTT.

Q6: What EPTT are your EPTTes currently being utilised?

A:Our EPTTes are commonly applied to metallurgical tools, mining products, EPTT gear, food EPTTry, EPTT tools, tobacco products and so on.

We are looking EPTT to your letter and inquiry. You are welcome to arrive to EPTT for inspection at any time:

in Leicester United Kingdom sales price shop near me near me shop factory supplier High Efficiency Energy Saving Nmrv Replacement Hypoid Gearbox manufacturer best Cost Custom Cheap wholesaler

The group has taken portion in the producing and revising of ISO/TC100 international chain normal several many years in achievement and hosted the 16th ISO/TC100 International yearly assembly in 2004. With EPG brand registered in a lot more than 70 nations like America , Europe , Japan and so on, it has companions among globe prime enterprises, this sort of as JOHNDEERE, NEW HOLLAND, CLAAS, HONDA, KUBOTA, YANMAR, etc. PersonnelOur revenue folks are effectively qualified to accommodate your requests and communicate English for your usefulness.

KPM collection helical-hypoid EPTTes are the new-technology product with a compromise of EPTT EPTT both at residence and abroad.

This product is extensively utilized in textile, foodstuff, EPTTrage,tobacco, EPTT EPTT fields,and so forth.

KPM series hypoid gearbox’s features are as follows:

(1) Pushed by hypoid EPTTs, which has huge ratios.

(two) Massive output torque, substantial effectiveness(up to ninety two%), energy preserving and environmental protection.

(three) Large quality EPTT alloy housing, ligEPTT in weigEPTT and non-rusting.

(4) Clean in working and low in sound, and can function EPTT time in dreadful conditions.

(five) Excellent-looking appearance, tough provider lifestyle and modest volume.

(6) Suited for all spherical installation, vast application and easy use.

(seven) The mounting proportions of KPM sequence helical-hypoid EPTTes are compatible with RV collection worm EPTTes(some dimensions of RV50 are diverse from KPM50).

(eight) Modular and multi-construction can fulfill the requires of various conditions.

KPM series hypoid gearbox’s Principal EPTT:

(one) EPTT: EPTT alloy (body dimension fifty-sixty three-seventy five-90)

(two) Equipment wheel: 20CrMnTiH1,carbonize amp quencher heat therapy make the hardness of EPTTs area up to 56-62 EPTC, keep carburization levels thickness in between .3 and .5mm after exact grinding.

| EPTT Deciding on TABLES | ||||||||||||

| KPM50.. | n1=1400r/min | 160Nm | ||||||||||

| Product | i | i | n2 | M2max | Fr2 | 63B5 | 71B5/B14 | 80B5/B14 | 90B5/B14 | |||

| nominal | true | [r/min] | [Nm] | [N] | ||||||||

| three Stage | ||||||||||||

| KPM50C | 300 | 294.05 | four.8 | one hundred thirty | 4100 | N/A | N/A | N/A | ||||

| KPM50C | 250 | 244.29 | five.eight | a hundred thirty | 4100 | N/A | N/A | N/A | ||||

| KPM50C | two hundred | 200.44 | seven. | one hundred thirty | 4100 | N/A | N/A | N/A | ||||

| KPM50C | 150 | 146.67 | 9.six | one hundred sixty | 4000 | N/A | N/A | N/A | ||||

| KPM50C | one hundred twenty five | 120.34 | 12 | 160 | 3770 | N/A | N/A | |||||

| KPM50C | one hundred | a hundred and one.04 | 14 | one hundred sixty | 3560 | N/A | N/A | |||||

| KPM50C | 75 | 74.sixty two | 19 | one hundred sixty | 3220 | N/A | N/A | |||||

| KPM50C | 60 | 62.36 | 23 | one hundred sixty | 3030 | N/A | N/A | |||||

| KPM50C | 50 | fifty two.36 | 27 | one hundred sixty | 2860 | N/A | N/A | |||||

| two Stage | ||||||||||||

| KPM50B | 60 | fifty eight.36 | 24 | a hundred thirty | 2960 | N/A | N/A | |||||

| KPM50B | fifty | forty eight.86 | 29 | a hundred thirty | 2790 | N/A | ||||||

| KPM50B | 40 | 40.09 | 35 | one hundred thirty | 2610 | N/A | ||||||

| KPM50B | 30 | 29.33 | forty eight | a hundred and sixty | 2350 | N/A | ||||||

| KPM50B | 25 | 24.07 | fifty nine | one hundred sixty | 2200 | |||||||

| KPM50B | twenty | 20.21 | 70 | a hundred and sixty | 2080 | |||||||

| KPM50B | fifteen | fourteen.ninety two | 94 | one hundred sixty | 1880 | |||||||

| KPM50B | 12.5 | twelve.forty seven | 113 | one hundred sixty | 1770 | |||||||

| KPM50B | ten | ten.47 | 134 | one hundred sixty | 1670 | |||||||

| KPM50B | 7.five | seven.73 | 182 | 160 | 1510 | |||||||

| KPM63..,KPB63.. | n1=1400r/min | 180Nm | ||||||||||

| Model | i | i | n2 | M2max | Fr2 | 63B5 | 71B5/B14 | 80B5/B14 | 90B5/B14 | |||

| nominal | actual | [r/min] | [Nm] | [N] | ||||||||

| 3 Stage | ||||||||||||

| KPM63C | KPB63C | 300 | 302.fifty | 4.7 | 160 | 4800 | N/A | N/A | N/A | |||

| KPM63C | KPB63C | 250 | 243.57 | 5.8 | one hundred sixty | 4800 | N/A | N/A | N/A | |||

| KPM63C | KPB63C | 200 | 196.43 | 7.two | 160 | 4800 | N/A | N/A | ||||

| KPM63C | KPB63C | a hundred and fifty | 151.56 | nine.three | 180 | 4650 | N/A | N/A | ||||

| KPM63C | KPB63C | one hundred twenty five | 122.22 | 12 | a hundred and eighty | 4330 | N/A | N/A | ||||

| KPM63C | KPB63C | a hundred | ninety four.50 | fourteen | 180 | 4070 | N/A | N/A | ||||

| KPM63C | KPB63C | seventy five | seventy three.33 | 20 | 180 | 3650 | N/A | |||||

| KPM63C | KPB63C | sixty | 63.33 | 23 | a hundred and eighty | 3480 | N/A | |||||

| KPM63C | KPB63C | 50 | 52.forty eight | 27 | one hundred eighty | 3270 | N/A | |||||

| 2 Stage | ||||||||||||

| KPM63B | KPB63B | sixty | 60.fifty | 24 | a hundred and sixty | 3430 | N/A | |||||

| KPM63B | KPB63B | 50 | 48.71 | 29 | a hundred and sixty | 3190 | ||||||

| KPM63B | KPB63B | 40 | 39.29 | 36 | a hundred and sixty | 2970 | ||||||

| KPM63B | KPB63B | thirty | thirty.31 | 47 | a hundred and eighty | 2720 | ||||||

| KPM63B | KPB63B | twenty five | 24.44 | 58 | one hundred eighty | 2530 | N/A | |||||

| KPM63B | KPB63B | 20 | 18.ninety | 70 | one hundred eighty | 2380 | N/A | |||||

| KPM63B | KPB63B | 15 | 14.sixty seven | ninety six | a hundred and eighty | 2130 | N/A | N/A | ||||

| KPM63B | KPB63B | twelve.5 | twelve.sixty seven | 111 | 180 | 2030 | N/A | N/A | ||||

| KPM63B | KPB63B | ten | 10.fifty | 134 | one hundred eighty | 1910 | N/A | N/A | ||||

| KPM63B | KPB63B | 7.5 | 7.60 | 185 | one hundred eighty | 1710 | N/A | N/A | ||||

| KPM75..,KPB75.. | n1=1400r/min | 350Nm | ||||||||||

| Design | i | i | n2 | M2max | Fr2 | 63B5 | 71B5 | 80B5/B14 | 90B5/B14 | 100B5/B14 | 112B5/B14 | |

| nominal | real | [r/min] | [Nm] | [N] | ||||||||

| three Phase | ||||||||||||

| KPM75C | KPB75C | 300 | 297.21 | 4.8 | three hundred | 6500 | N/A | N/A | N/A | N/A | ||

| KPM75C | KPB75C | 250 | 240.89 | five.nine | three hundred | 6500 | N/A | N/A | N/A | N/A | ||

| KPM75C | KPB75C | 200 | two hundred.66 | 7. | 300 | 6500 | N/A | N/A | N/A | N/A | ||

| KPM75C | KPB75C | a hundred and fifty | 149.30 | 9.three | 350 | 6500 | N/A | N/A | N/A | |||

| KPM75C | KPB75C | one hundred twenty five | 121.00 | 12 | 350 | 5980 | N/A | N/A | N/A | |||

| KPM75C | KPB75C | a hundred | one hundred.eighty | 15 | 350 | 5520 | N/A | N/A | N/A | |||

| KPM75C | KPB75C | 75 | seventy nine.40 | 19 | 350 | 5040 | N/A | N/A | ||||

| KPM75C | KPB75C | sixty | sixty two.43 | 23 | 350 | 4730 | N/A | N/A | N/A | |||

| KPM75C | KPB75C | 50 | 49.eighteen | 29 | 350 | 4370 | N/A | N/A | N/A | |||

| two Stage | ||||||||||||

| KPM75B | KPB75B | 60 | fifty nine.forty four | 24 | three hundred | 4660 | N/A | N/A | N/A | |||

| KPM75B | KPB75B | 50 | 48.eighteen | 30 | three hundred | 4340 | N/A | N/A | N/A | |||

| KPM75B | KPB75B | forty | forty.thirteen | 35 | 300 | 4080 | N/A | N/A | ||||

| KPM75B | KPB75B | 30 | 29.86 | 47 | 350 | 3720 | N/A | N/A | N/A | |||

| KPM75B | KPB75B | 25 | 24.20 | 56 | 350 | 3500 | N/A | N/A | ||||

| KPM75B | KPB75B | twenty | 20.sixteen | 71 | 350 | 3230 | N/A | N/A | ||||

| KPM75B | KPB75B | 15 | fifteen.88 | ninety three | 350 | 2950 | N/A | N/A | ||||

| KPM75B | KPB75B | twelve.5 | 12.49 | 113 | 350 | 2770 | N/A | N/A | N/A | |||

| KPM75B | KPB75B | ten | nine.84 | 143 | 350 | 2550 | N/A | N/A | N/A | |||

| KPM75B | KPB75B | seven.five | seven.48 | 188 | 350 | 2330 | N/A | N/A | N/A | |||

| KPM90..,KPB86.. | n1=1400r/min | 500Nm | ||||||||||

| Model | i | i | n2 | M2max | Fr2 | 63B5 | 71B5 | 80B5/B14 | 90B5/B14 | 100B5/B14 | 112B5/B14 | |

| nominal | actual | [r/min] | [Nm] | [N] | ||||||||

| 3 Stage | ||||||||||||

| KPM90C | KPB86C | 300 | 297.21 | 4.8 | 450 | 6500 | N/A | N/A | N/A | N/A | ||

| KPM90C | KPB86C | 250 | 240.89 | 5.9 | 450 | 6500 | N/A | N/A | N/A | |||

| KPM90C | KPB86C | 200 | 200.sixty six | 7. | 450 | 6500 | N/A | N/A | N/A | |||

| KPM90C | KPB86C | a hundred and fifty | 151.twenty | 9.three | 500 | 6500 | N/A | N/A | N/A | |||

| KPM90C | KPB86C | one hundred twenty five | one hundred twenty five.95 | twelve | five hundred | 5980 | N/A | N/A | N/A | |||

| KPM90C | KPB86C | a hundred | ninety nine.22 | fifteen | five hundred | 5520 | N/A | N/A | N/A | |||

| KPM90C | KPB86C | 75 | seventy five.45 | 19 | five hundred | 5040 | N/A | N/A | N/A | |||

| KPM90C | KPB86C | 60 | 62.43 | 23 | 500 | 4730 | N/A | N/A | N/A | |||

| KPM90C | KPB86C | fifty | 49.eighteen | 29 | 500 | 4370 | N/A | N/A | N/A | |||

| two Phase | ||||||||||||

| KPM90B | KPB86B | sixty | fifty nine.forty four | 24 | 450 | 5890 | N/A | N/A | ||||

| KPM90B | KPB86B | 50 | 48.18 | 30 | 450 | 5500 | N/A | N/A | ||||

| KPM90B | KPB86B | 40 | forty.thirteen | 35 | 450 | 5170 | N/A | N/A | ||||

| KPM90B | KPB86B | thirty | 30.24 | forty seven | five hundred | 4710 | N/A | N/A | ||||

| KPM90B | KPB86B | twenty five | 25.19 | fifty six | five hundred | 4430 | N/A | N/A | ||||

| KPM90B | KPB86B | twenty | 19.eighty four | 71 | 500 | 4090 | N/A | N/A | N/A | |||

| KPM90B | KPB86B | 15 | fifteen.09 | ninety three | 500 | 3730 | N/A | N/A | N/A | |||

| KPM90B | KPB86B | twelve.5 | 12.49 | 113 | 500 | 3510 | N/A | N/A | N/A | |||

| KPM90B | KPB86B | 10 | nine.84 | 143 | 500 | 3240 | N/A | N/A | N/A | |||

| KPM90B | KPB86B | 7.five | seven.forty eight | 188 | 500 | 2950 | N/A | N/A | N/A | |||

Firm Quick INTRODUCTION:

We are a professional EPTT maker positioned in EPTTizhou, EPTT province.

Our top items is complete assortment of RV571-a hundred and fifty worm EPTTs , also equipped hypoid helical EPTT, Pc units, UDL Variators and AC EPTTs.

EPTT are extensively employed for apps this sort of as: foodstuffs, EPTT, EPTT, chemicals, pharmacy, plastics, paper-creating, construction EPTTry, metallurgic EPTT, environmental protection engineering, and all kinds of automated strains, and assembly lines.

With quickly delivery, superior following-product sales service, EPTT generating faXiHu (West Lake) Dis.Hu (West Lake) Dis.ty, our merchandise offer well the two at house and abroad. We have exported our EPTTs to SouthEPTT Asia, EPTTern Europe and the Center EPTT and so on.Our purpose is to deveXiHu (West Lake) Dis.Hu (West Lake) Dis. and innovate on the basis of substantial good quality, and EPTT a very good status for EPTTs.

WORKSHOP:

EXHIBITIONS:

FAQ:

1.Q:Can you make as per consumer drawing?

A: Indeed, we supply EPT service for customers accordingly. We can use customer’s nameplate for EPTTes.

2.Q:What is your conditions of payment ?

A: 30% deposit ahead of creation,balance T/T prior to shipping.

three.Q:Are you a investing firm or company?

A:We are a manufacurer with EPTT equipment and skilled employees.

four.Q:What’s your manufacturing potential?

A:8000-9000 PCS/Month

four.Q:What is your MOQ?

A: one pcs

five.Q:Totally free sample is obtainable or not?

A:Yes, we can supply free of charge sample if consumer agree to spend for the courier EPTT

six.Q:Do you have any certificate?

A:Sure, we have CE certification and SGS certificate report.

Get in touch with info:

Ms Lingel Pan

For any inquiries just come to feel totally free ton get in touch with me. A lot of thanks for your variety attention to our company!