Product Description

Product Description

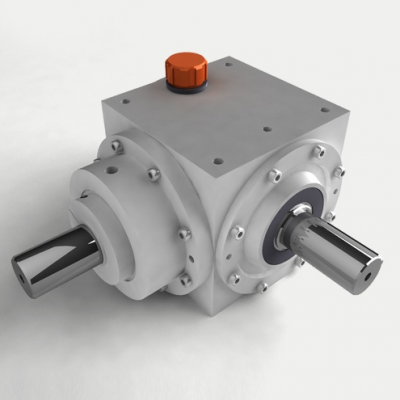

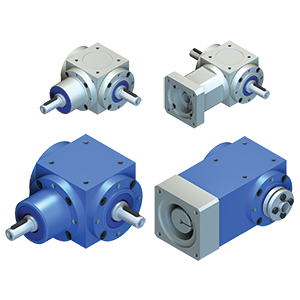

-K Series Helical Bevel Gearbox

K series gear reducer, manufactured according to international technical requirements, has a high scientific and technological content; Space saving, reliable and durable, high overload capacity, power up to 132KW; Low energy consumption, superior performance, reducer efficiency up to 95%

It is designed and manufactured on the basis of module combination system. There are a lot of motor combinations, installation forms and structural schemes. The transmission ratio is classified carefully to meet different operating conditions and realize electromechanical integration.

High transmission efficiency, low energy consumption and superior performance.

Reinforced high rigid cast iron box; The hardened gear is made of high-quality alloy steel. Its surface is carburized, quenched and hardened, and the gear is finely ground. It features stable transmission, low noise, large bearing capacity, low temperature rise, and long service life. Performance and characteristics:

1. The gear is carburized and quenched with high-quality alloy, the hardness of the tooth surface is up to 60 ± 2hrc, and the grinding accuracy of the tooth surface is up to 5-6

2. The computer modification technology is used to pre modify the gear, which greatly improves the bearing capacity of the reducer

3. Complete modular structure design is adopted from the box to the internal gear, which is suitable for large-scale production and flexible selection

4. The standard reducer models are divided according to the form of decreasing torque. Compared with the traditional equal proportion division, they are more in line with customer requirements and avoid power waste

5. It is designed and manufactured by cad/cam to ensure the stability of quality

6. Multiple sealing structures are adopted to prevent oil leakage

7. Multi directional noise reduction measures to ensure the excellent low noise performance of the reducer

8. The installation mode of Liyi products is flexible, which makes it easy for customers to choose K57 reducer, K67 reducer, K77 reducer, K87 reducer, K97 reducer, KA87 reducer, KA97 reducer, KA107 reducer, KA127 reducer

Product Features

1. Input mode: Coupled motor, belted motor, input shaft or connection flange.

2. Output: Right angle

3. Compact structure. Rigid tooth face. Carrying greater torque, high loading capacity.

4.High precision gear, ensuring the unit to operate stably, smooth transmission.

5. Low noise, long lifespan. Large overlap coefficient, abrasion resistant.

Our product line

| Hardness: | Hardened Tooth Surface |

|---|---|

| Installation: | 90 Degree |

| Layout: | Expansion |

| Gear Shape: | Bevel Gear |

| Step: | Single-Step |

| Type: | Gear Reducer |

| Samples: |

US$ 1000/Piece

1 Piece(Min.Order) | |

|---|

Torque and Load Distribution in Spiral Bevel Gearboxes

Spiral bevel gearboxes are designed to efficiently handle torque and distribute loads across their gear teeth. The unique geometry of spiral bevel

Precision Applications of Spiral Bevel Gearboxes

Spiral bevel gearboxes are well-suited for precision applications that require accurate and controlled motion. Here’s how they can be used in precision settings:

1. Automotive Manufacturing: Spiral bevel gearboxes play a critical role in automotive assembly lines, where precision is essential for proper alignment and fit of components. They help in controlling robotic arms, conveyors, and tool movements with high accuracy.

2. Aerospace Industry: In the aerospace sector, precision is paramount. Spiral bevel gearboxes are used in various applications, including aircraft landing gear systems, where they enable controlled and accurate movement during takeoff and landing.

3. Medical Equipment: Medical devices, such as robotic surgical systems and imaging equipment, require precise and reliable motion control. Spiral bevel gearboxes ensure accurate positioning and movement in these critical applications.

4. Semiconductor Manufacturing: The semiconductor industry demands extreme precision for the fabrication of microchips. Spiral bevel gearboxes are used in equipment like lithography machines, ensuring precise alignment and motion during the manufacturing process.

5. Optics and Instrumentation: Precision optics, telescopes, and scientific instruments require accurate adjustments and controlled movement. Spiral bevel gearboxes provide the necessary motion control for alignment and focusing.

6. Laboratory Automation: In research laboratories, spiral bevel gearboxes are utilized in robotic systems and automated equipment to handle delicate tasks with precision.

Thanks to their high-precision capabilities, spiral bevel gearboxes contribute to improved accuracy, repeatability, and reliability in a wide range of applications where precise motion control is critical.

gears contributes to their capability in managing torque and load distribution:

- Interlocking Teeth

Selecting a Spiral Bevel Gearbox: Key Considerations

Choosing the right spiral bevel gearbox for a specific application requires careful evaluation of various factors:

- Load Requirements: Determine the torque and load demands of the application to select a gearbox with an appropriate torque rating.

- Speed Range: Consider the desired speed range and ensure that the gearbox can handle the required speeds without compromising efficiency or durability.

- Environmental Conditions: Evaluate the operating environment, including temperature, humidity, and presence of dust or debris, to select suitable materials and sealing mechanisms.

- Mounting and Space Constraints: Assess available space and mounting requirements to ensure that the gearbox can be properly integrated into the machinery.

- Efficiency and Power Loss: Evaluate the gearbox’s efficiency to minimize energy loss and optimize power transmission.

- Noise and Vibration: Consider noise and vibration levels to ensure smooth and quiet operation, especially in applications where low noise is crucial.

- Maintenance and Serviceability: Choose a gearbox that is easy to maintain and service, with accessible lubrication points and inspection covers.

- Budget: Balance the required features and performance with the available budget for the gearbox.

- Manufacturer Reputation: Select a reputable manufacturer with a history of producing high-quality spiral bevel gearboxes.

By carefully evaluating these factors and collaborating with gearbox experts, you can make an informed decision and select a spiral bevel gearbox that meets the specific needs of your application.

:

Spiral bevel gears have curved teeth that gradually engage and disengage as they rotate. This design allows for smoother contact between the gears, reducing abrupt torque spikes and load shocks. - Multiple Contact Points: The spiral teeth provide multiple contact points along the gear tooth profile. This distributed contact helps spread the load evenly, minimizing concentrated stress points.

- High Tooth Engagement: The meshing of spiral bevel gears involves a significant amount of tooth engagement, ensuring that the load is distributed over a larger area of the gear teeth.

- Optimized Tooth Profile: The tooth profile of spiral bevel gears is designed to maintain consistent contact as the gears rotate. This optimized profile contributes to even load distribution.

- Precision Manufacturing: Spiral bevel gears are manufactured with high precision, ensuring accurate gear tooth profiles and minimal deviations. This precision results in uniform load distribution.

Overall, the interplay of these design features allows spiral bevel gearboxes to effectively manage torque and load distribution, leading to reliable and efficient power transmission.

editor by CX 2023-09-01