Product Description

| Product Features | Description |

| Product Models | T2, T4, T6, T7, T8, T10, T12, T16, T20, T25, Z2, Z4, Z6, Z7, Z8, Z10, Z12, Z16, Z20, Z25, JRTM2, JRTM4, JRTM6, JRTM7, JRTM8, JRTM10, JRTM12, JRTM16, JRTM20, JRTM25 |

| Maintenance | Clean internally and replace lubricant after initial use of 2 weeks or 100-200 hours. For long-term use, replace lubricant every half to 1 year or every 1000-2000 hours |

| Lubricant | China Petroleum’s all-effect gear oil of 90-120 degrees. Under low speed and light load conditions, it is recommended to use all-effect gear oil of 90 degrees. Under heavy load and high temperature conditions, it is recommended to use all-effect gear oil of 120 degrees |

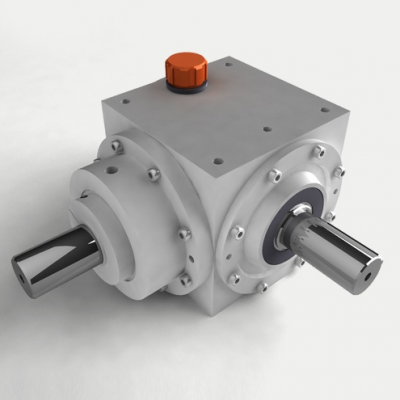

| Product Description | The T series spiral bevel gear steering gearbox is widely used in food, pharmaceutical, chemical, steel, metallurgy, textile, plastic, paper and other machinery equipment, assembly lines and other industries |

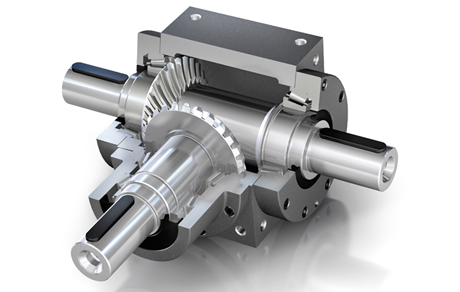

| Technical Features | The gearbox has a high rigidity FC-25 cast iron casing. The gears are made of high-quality high-purity alloy steel 20CrMnTi carburized and quenched, and ground. The shaft is tempered alloy steel with high load-bearing capacity. It is equipped with a heavy load-bearing tapered roller bearing. The oil seal has a double lip seal, which has dustproof and oil leakage prevention capabilities |

| Performance Features | The T series spiral bevel gear steering gearbox is standardized and has many varieties. The speed ratio is all actual transmission ratios, with an average efficiency of 98%. It can run CZPT and reverse, with smooth low-speed or high-speed transmission, low noise, small vibration, and large bearing force |

| Technical Parameters | Speed ratio range: 1/1, 1.5/1, 2/1, 2.5/1, 3/1, 4/1, 5/1. Torque range: 11.2 – 5713 Nm. Power range: 0.014 – 335 kW |

·Product Models: T2, T4, T6, T7, T8, T10, T12, T16, T20, T25, Z2, Z4, Z6, Z7, Z8, Z10, Z12, Z16, Z20, Z25, JRTM2, JRTM4, JRTM6, JRTM7, JRTM8, JRTM10, JRTM12, JRTM16, JRTM20, JRTM25.

·Maintenance: The gearbox should be cleaned internally and the lubricant should be replaced after the initial use of 2 weeks or 100-200 hours. For long-term use, the lubricant should be replaced every half to 1 year or every 1000-2000 hours.

·Lubricant: The product uses China Petroleum’s all-effect gear oil of 90-120 degrees. Under low speed and light load conditions, it is recommended to use all-effect gear oil of 90 degrees. Under heavy load and high temperature conditions, it is recommended to use all-effect gear oil of 120 degrees.

·Product Description: The T series spiral bevel gear steering gearbox is widely used in food, pharmaceutical, chemical, steel, metallurgy, textile, plastic, paper and other machinery equipment, assembly lines and other industries.

·Technical Features: The gearbox has a high rigidity FC-25 cast iron casing. The gears are made of high-quality high-purity alloy steel 20CrMnTi carburized and quenched, and ground. The shaft is tempered alloy steel with high load-bearing capacity. It is equipped with a heavy load-bearing tapered roller bearing. The oil seal has a double lip seal, which has dustproof and oil leakage prevention capabilities.

·Performance Features: The T series spiral bevel gear steering gearbox is standardized and has many varieties. The speed ratio is all actual transmission ratios, with an average efficiency of 98%. It can run CZPT and reverse, with smooth low-speed or high-speed transmission, low noise, small vibration, and large bearing force.

RFQ

Q:What information should I tell you to confirm speed reducer?

A: Model/Size, Transmission Ratio, Shaft directions & Order quantity.

Q:What if I don’t know which gear reducer I need?

A:Don’t worry, Send as much information as you can, our team will help you find the right 1 you are looking for.

Q:What should I provide if I want to order NON-STANDERD speed reducers?

A: Drafts, Dimensions, Pictures and samples if possible.

Q:What is the MOQ?

A: It is OK for 1 or small pieces trial order for quality testing.

Q:How long should I wait for the feedback after I send the inquiry?

A: Within 6 hours

Q:What is the payment term?

A:You can pay via T/T(30% in advance+70% before delivery), L/C ,West Union etc

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Coaxial |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Three-Step |

| Samples: |

Contribution of Spiral Bevel Gearboxes to Mechanical System EfficiencySpiral bevel gearboxes play a crucial role in enhancing the overall efficiency of mechanical systems by:

By effectively transmitting power, optimizing torque distribution, reducing friction, and providing smooth and reliable operation, spiral bevel gearboxes significantly enhance the overall efficiency of mechanical systems in various industries. US$ 100/Piece | |

|---|

Advantages of Using Spiral Bevel Gearboxes in Industrial Applications

Spiral bevel gearboxes offer several advantages when used in industrial applications:

- High Efficiency: Spiral bevel gearboxes have high efficiency due to the smooth and gradual meshing of their angled teeth. This redu

Disadvantages and Limitations of Spiral Bevel Gear Systems

Spiral bevel gear systems offer many advantages, but they also come with some disadvantages and limitations:

- Complex Manufacturing: The manufacturing process for spiral bevel gears is more intricate and time-consuming than for some other gear types, leading to potentially higher costs.

- Higher Noise Levels: While spiral bevel gears are designed to minimize noise, they can still produce more noise than other gear types, particularly at high speeds.

- Increased Friction and Heat: The meshing action of spiral bevel gears generates more friction and heat compared to some other gear systems, which may require more robust lubrication and cooling mechanisms.

- Less Suitable for High-Speed Applications: While spiral bevel gears can operate at high speeds, their design may make them less suitable for extremely high-speed applications where other gear types, such as helical gears, may be preferred.

- Complex Maintenance: Disassembling and assembling spiral bevel gearboxes can be more complex and time-consuming due to the precision required for gear meshing and alignment.

- Specific Installation Requirements: Spiral bevel gears require precise alignment during installation to ensure proper meshing and performance, which can add complexity to the assembly process.

- Space Limitations: The configuration of spiral bevel gears requires more axial space compared to some other gear types, which may be a limitation in applications with restricted space.

Despite these disadvantages, spiral bevel gear systems remain a valuable choice in various industrial applications where their benefits outweigh the limitations.

ces friction and power loss during gear operation.

- Robust and Durable: The design of spiral bevel gears provides robustness and durability, allowing them to handle heavy loads and high torque without premature wear.

- Compact Design: Spiral bevel gearboxes have a compact and space-saving design, making them suitable for applications with limited installation space.

- Smooth Operation: The gradual tooth engagement of spiral bevel gears results in smoother and quieter operation compared to straight bevel gears, minimizing noise and vibration.

- Direction Changes: Spiral bevel gearboxes are ideal for applications requiring changes in the direction of power transmission due to their intersecting shafts at right angles.

- High Torque Transmission: The larger contact area of the spiral bevel gear teeth allows for efficient and reliable transmission of high torque, making them suitable for heavy-duty applications.

- Reliable Power Transmission: Spiral bevel gearboxes ensure accurate and consistent power transmission between intersecting shafts, reducing the risk of gear slippage or misalignment.

- Wide Range of Applications: Spiral bevel gearboxes find use in a variety of industrial applications, including automotive, aerospace, mining, construction, and manufacturing.

- Customization: Manufacturers can customize spiral bevel gearboxes to meet specific application requirements, such as gear ratios, input and output shaft sizes, and mounting options.

Overall, the advantages of spiral bevel gearboxes make them a preferred choice in industrial settings where efficient, reliable, and precise power transmission is essential.

editor by CX 2023-09-01