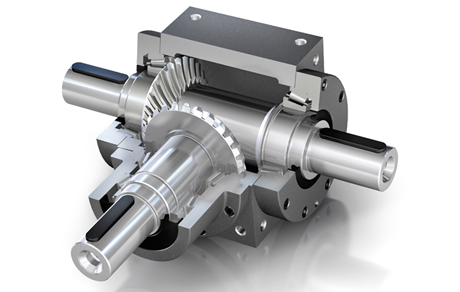

Product Description

| Product Features | Description |

| Product Models | T2, T4, T6, T7, T8, T10, T12, T16, T20, T25, Z2, Z4, Z6, Z7, Z8, Z10, Z12, Z16, Z20, Z25, JRTM2, JRTM4, JRTM6, JRTM7, JRTM8, JRTM10, JRTM12, JRTM16, JRTM20, JRTM25 |

| Maintenance | Clean internally and replace lubricant after initial use of 2 weeks or 100-200 hours. For long-term use, replace lubricant every half to 1 year or every 1000-2000 hours |

| Lubricant | China Petroleum’s all-effect gear oil of 90-120 degrees. Under low speed and light load conditions, it is recommended to use all-effect gear oil of 90 degrees. Under heavy load and high temperature conditions, it is recommended to use all-effect gear oil of 120 degrees |

| Product Description | The T series spiral bevel gear steering gearbox is widely used in food, pharmaceutical, chemical, steel, metallurgy, textile, plastic, paper and other machinery equipment, assembly lines and other industries |

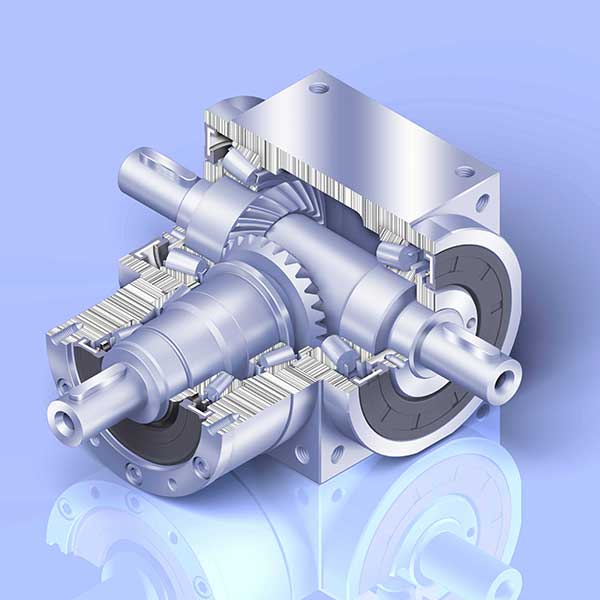

| Technical Features | The gearbox has a high rigidity FC-25 cast iron casing. The gears are made of high-quality high-purity alloy steel 20CrMnTi carburized and quenched, and ground. The shaft is tempered alloy steel with high load-bearing capacity. It is equipped with a heavy load-bearing tapered roller bearing. The oil seal has a double lip seal, which has dustproof and oil leakage prevention capabilities |

| Performance Features | The T series spiral bevel gear steering gearbox is standardized and has many varieties. The speed ratio is all actual transmission ratios, with an average efficiency of 98%. It can run CZPT and reverse, with smooth low-speed or high-speed transmission, low noise, small vibration, and large bearing force |

| Technical Parameters | Speed ratio range: 1/1, 1.5/1, 2/1, 2.5/1, 3/1, 4/1, 5/1. Torque range: 11.2 – 5713 Nm. Power range: 0.014 – 335 kW |

·Product Models: T2, T4, T6, T7, T8, T10, T12, T16, T20, T25, Z2, Z4, Z6, Z7, Z8, Z10, Z12, Z16, Z20, Z25, JRTM2, JRTM4, JRTM6, JRTM7, JRTM8, JRTM10, JRTM12, JRTM16, JRTM20, JRTM25.

·Maintenance: The gearbox should be cleaned internally and the lubricant should be replaced after the initial use of 2 weeks or 100-200 hours. For long-term use, the lubricant should be replaced every half to 1 year or every 1000-2000 hours.

·Lubricant: The product uses China Petroleum’s all-effect gear oil of 90-120 degrees. Under low speed and light load conditions, it is recommended to use all-effect gear oil of 90 degrees. Under heavy load and high temperature conditions, it is recommended to use all-effect gear oil of 120 degrees.

·Product Description: The T series spiral bevel gear steering gearbox is widely used in food, pharmaceutical, chemical, steel, metallurgy, textile, plastic, paper and other machinery equipment, assembly lines and other industries.

·Technical Features: The gearbox has a high rigidity FC-25 cast iron casing. The gears are made of high-quality high-purity alloy steel 20CrMnTi carburized and quenched, and ground. The shaft is tempered alloy steel with high load-bearing capacity. It is equipped with a heavy load-bearing tapered roller bearing. The oil seal has a double lip seal, which has dustproof and oil leakage prevention capabilities.

·Performance Features: The T series spiral bevel gear steering gearbox is standardized and has many varieties. The speed ratio is all actual transmission ratios, with an average efficiency of 98%. It can run CZPT and reverse, with smooth low-speed or high-speed transmission, low noise, small vibration, and large bearing force.

RFQ

Q:What information should I tell you to confirm speed reducer?

A: Model/Size, Transmission Ratio, Shaft directions & Order quantity.

Q:What if I don’t know which gear reducer I need?

A:Don’t worry, Send as much information as you can, our team will help you find the right 1 you are looking for.

Q:What should I provide if I want to order NON-STANDERD speed reducers?

A: Drafts, Dimensions, Pictures and samples if possible.

Q:What is the MOQ?

A: It is OK for 1 or small pieces trial order for quality testing.

Q:How long should I wait for the feedback after I send the inquiry?

A: Within 6 hours

Q:What is the payment term?

A:You can pay via T/T(30% in advance+70% before delivery), L/C ,West Union etc

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Coaxial |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Three-Step |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) Assembly and Disassembly of Spiral Bevel GearboxesAssembly: The process of assembling spiral bevel gearboxes involves several steps: a. Preparing Components: Gather all the required components, including gears, bearings, shafts, and housing. b. Gear Placement: Place the spiral bevel gears onto the designated shafts, ensuring proper alignment and meshing of the gear teeth. c. Bearing Installation: Install the bearings onto the shafts to support the rotating components. Ensure correct positioning and fit. d. Housing Alignment: Carefully position the gearbox housing and ensure proper alignment with the shafts and gears. e. Sealing: Install seals and gaskets to prevent lubricant leakage and maintain internal cleanliness. f. Fastening: Secure the housing using bolts, ensuring even torque distribution for a stable assembly. Disassembly: The disassembly process is performed in reverse order: a. Housing Removal: Start by removing the housing bolts and separating the housing from the internals. b. Bearing Removal: Remove the bearings from the shafts using suitable tools and techniques. c. Gear Removal: Carefully slide the gears off the shafts, taking note of their orientation and alignment. d. Component Inspection: Inspect all components for wear, damage, or signs of fatigue that may require replacement. e. Cleaning: Thoroughly clean all parts, ensuring the removal of dirt, debris, and old lubricants. f. Reassembly: Reassemble the gearbox components, following the correct sequence and ensuring proper alignment and meshing. g. Lubrication: Apply the appropriate lubricant to the gears, bearings, and other moving parts. h. Housing Fastening: Reattach the housing and tighten the bolts to the specified torque. i. Functional Testing: Perform functional tests to ensure smooth rotation, proper gear engagement, and no abnormal noises. Both assembly and disassembly require precision and careful attention to detail to maintain the performance and reliability of spiral bevel gearboxes. | |

|---|

Differences Between Spiral Bevel Gearboxes and Other Gearbox Types

Spiral bevel gearboxes differ from other gearbox types in several key aspects:

- Gear Tooth Design: Spiral bevel gearboxes use spiral bevel gears with angled teeth, which allow for smoother meshing and reduced impact compared to straight bevel gears. In contrast, other gearbox types might use spur gears, helical gears, or worm gears, each with distinct tooth profiles.

- Shaft Arrangement: Spiral bevel gearboxes have intersecting input and output shafts set at right angles. This enables power transmission between shafts that are not aligned. Other gearbox types, such as parallel shaft gearboxes, have shafts that are parallel to each other.

- Direction Changes: Spiral bevel gearboxes are well-suited for applications requiring direction changes between input and output shafts due to their perpendicular shaft arrangement. Worm gearboxes, on the other hand, are commonly used for large speed reductions and right-angle drives.

- High Torque Transmission: Spiral bevel gearboxes offer high torque transmission capabilities due to the larger contact area of their gear teeth. Planetary gearboxes, while also capable of handling high torque, have a different gear arrangement involving sun, planet, and ring gears.

- Noise and Vibration: Spiral bevel gearboxes tend to produce less noise and vibration compared to straight bevel gearboxes, thanks to their spiral tooth design. Helical gearboxes, which also use angled teeth, offer similar advantages in terms of noise reduction.

- Applications: Spiral bevel gearboxes are commonly used in automotive differentials, aerospace systems, and heavy machinery. Other gearbox types find applications in various industries based on their unique characteristics and advantages.

Overall, the distinctive features of spiral bevel gearboxes set them apart from other gearbox types, making them suitable for specific applications where direction changes, torque transmission, and smooth operation are critical factors.

editor by CX 2023-08-30