Product Description

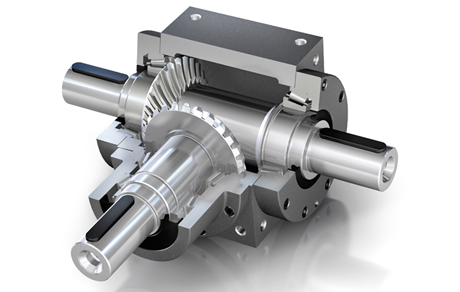

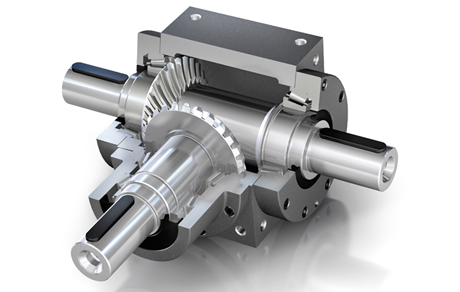

Bevel gearboxes: A bevel gearbox enables alternatively stepping-down or stepping-up. The axles intersect in the gearbox in an angle of 90°. The edge length of the housing is reflected in the gearbox size. Features include Robust, powerful, compact, Housing made of grey cast iron or steel, Spiral-toothed gear sets, and Maintenance-free. Application examples in Automation, Transfer gearboxes, Packaging machines, Linear technology, and Machine and plant construction.

How Does A Spiral Bevel Gearbox Work?

Right Angle Bevel Gearboxes Videos For Customers Orders

* Thailand customer 3:1 Right Angle Gear Reducer | Gearboxes | 32 MM Dia. Shafts | Power Transmission Video:

* Australia client JT15 light weight bevel gear box 1:1 ratio 90 degree gearbox small 1input 2output Video:

* India customer JT25 90 degree reduction drives 1:1 and 2:1 bevel gearbox 25 mm shaft Video:

* Canada customer synchronous screw jack lift system with 4 1 ton ball screw worm gear jacks lift Video:

* Canada customer jack screw elevator systems with 4 1-ton CZPT screw actuator and 2 90deg. gearboxes Video:

* America customer 2.5 tons screw jack for work table adjustment/motorised power the lifting systems Video:

* Singapore two-way spiral bevel gearboxes 1:1 ratio are application in bevel gear screw jacks tables Video:

* Malaysia client high speed 1″ (25mm) shaft right angle gearbox for screw jack lifting systems Video:

* Indonesia client 2-way 3-way 4-way right angle gearbox 1:1 ratio synchronous transmission systems Video:

* Slovenia Screw jack lifting table or Platform with Four ten-ton travel nut screw jacks and gearboxes Video:

* Vietnam Ho Chi Minh City customer right angle drive 1:1 gearbox 32mm horizontal to vertical gear box Video:

* Malaysia client jack system with 4 worm gear screw jacks and 2 bevel gear boxes Video:

* 16567X3, registered Capital 500000CNY) is a leading manufacturer and supplier of Screw Jacks (Mechanical Actuators), Bevel Gearboxes, Lifting Systems, Electric Linear Actuators, Gearmotors and Speed Reducers, and Others Linear Motion and Power Transmission Products in China. We are Alibaba, Made-In-China and SGS (Serial NO.: QIP-ASI192186) audited manufacturer and supplier. We also have a strict quality system, with senior engineers, experienced skilled workers and practiced sales teams, we consistently provide the high quality equipments to meet the customers electro-mechanical actuation, lifting and positioning needs. CZPT Industry guarantees quality, reliability, performance and value for today’s demanding industrial applications.

Website (English): screw-jacks

Website (English): screw-jacks

Website (Chinese): screw-jacks

| Application: | Motor, Machinery, Agricultural Machinery, Car, Metrology and Test Engineering |

|---|---|

| Function: | Distribution Power, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase, Transmission |

| Layout: | Right Angle Drive |

| Hardness: | Hardened Tooth Surface |

| Installation: | Universal Mounting |

| Step: | Single-Step |

| Customization: |

Available

| Customized Request |

|---|

Contribution to Machine Efficiency by Spiral Bevel Gearboxes

Spiral bevel gearboxes play a significant role in enhancing machine efficiency across various applications. Their design features and characteristics contribute to improved overall performance:

- High Efficiency: The tooth engagement of spiral bevel gears results in smooth and continuous contact, minimizing friction and energy loss. This high mechanical efficiency translates to reduced power consumption and enhanced machine efficiency.

- Load Distribution: The spiral tooth profile allows for a larger contact area between gear teeth, enabling even distribution of loads. This prevents localized stress concentrations, reduces wear, and extends the lifespan of both gears and bearings.

- Precision Manufacturing: The precision manufacturing techniques used in spiral bevel gearboxes ensure accurate gear tooth geometry and proper alignment. This precision minimizes energy losses due to misalignment or irregular tooth contact.

- Reduced Heat Generation: The efficient tooth engagement and load distribution in spiral bevel gears result in reduced friction and heat generation. This helps maintain optimal operating temperatures and prevents energy losses due to heat dissipation.

- Compact Design: Spiral bevel gearboxes are designed with a compact and space-efficient layout. Their ability to transmit high torques within a smaller footprint contributes to efficient machine designs and space utilization.

- Smooth Operation: The gradual tooth engagement and reduced impact forces in spiral bevel gear systems contribute to smoother and quieter operation. This promotes consistent machine performance and minimizes downtime due to vibrations or noise-related issues.

By enhancing mechanical efficiency, load distribution, and overall machine performance, spiral bevel gearboxes contribute to energy savings, extended equipment lifespan, and improved productivity in various industrial applications.

Disadvantages and Limitations of Spiral Bevel Gear Systems

Spiral bevel gear systems offer many advantages, but they also come with some disadvantages and limitations:

- Complex Manufacturing: The manufacturing process for spiral bevel gears is more intricate and time-consuming than for some other gear types, leading to potentially higher costs.

- Higher Noise Levels: While spiral bevel gears are designed to minimize noise, they can still produce more noise than other gear types, particularly at high speeds.

- Increased Friction and Heat: The meshing action of spiral bevel gears generates more friction and heat compared to some other gear systems, which may require more robust lubrication and cooling mechanisms.

- Less Suitable for High-Speed Applications: While spiral bevel gears can operate at high speeds, their design may make them less suitable for extremely high-speed applications where other gear types, such as helical gears, may be preferred.

- Complex Maintenance: Disassembling and assembling spiral bevel gearboxes can be more complex and time-consuming due to the precision required for gear meshing and alignment.

- Specific Installation Requirements: Spiral bevel gears require precise alignment during installation to ensure proper meshing and performance, which can add complexity to the assembly process.

- Space Limitations: The configuration of spiral bevel gears requires more axial space compared to some other gear types, which may be a limitation in applications with restricted space.

Despite these disadvantages, spiral bevel gear systems remain a valuable choice in various industrial applications where their benefits outweigh the limitations.

Principles of Spiral Bevel Gear Meshing

Spiral bevel gears operate based on the principles of involute gearing and the meshing of angled teeth. Here’s how the gear meshing process works:

- Involute Profile: Like other gear types, spiral bevel gears have involute profiles on their gear teeth. This profile ensures smooth and gradual tooth engagement during meshing, reducing impact and wear.

- Curved Tooth Surface: The gear teeth on spiral bevel gears are curved along the face width, allowing for gradual and continuous contact as the gears rotate. This design minimizes abrupt changes in contact and reduces noise and vibration.

- Intersecting Axes: Spiral bevel gears have axes that intersect at a right angle. This arrangement allows power transmission between two perpendicular shafts, making them suitable for applications requiring changes in direction.

- Angular Tooth Orientation: The main feature of spiral bevel gears is their angled tooth orientation. Each gear tooth has both radial and axial angles, which contribute to smoother tooth engagement and reduced sliding friction.

- Curved Tooth Alignment: As the gears rotate, the curved surfaces of the teeth align in a way that enables gradual meshing. This results in a rolling contact motion, unlike the sliding contact motion found in straight bevel gears.

- Constant Contact Ratio: The unique geometry of spiral bevel gears maintains a constant contact ratio throughout the gear meshing cycle. This consistent contact ratio ensures smooth operation and even distribution of load.

Overall, the principles of spiral bevel gear meshing lead to quieter operation, improved efficiency, and greater load-carrying capacity compared to other types of bevel gears.

editor by CX 2023-09-06